Advant

®

Controller 450 User’s Guide

Section 2.2.10 S100 I/O

3BSE 002 415R701 Rev A 2-37

Readjustment

AO boards are factory adjusted for voltage output signals. If current signal is desired/jumpered,

you must readjust for maximum accuracy. Please follow the instructions found in Section

5.5.12, Channel Adjustment on AO Board.

Preparation for Start-up

Check of the External Wiring

Judge the level of workmanship case by case. The result determines the need to thoroughly

check all connections before the system is powered up.

You can, of course, check with a buzzer or similar device that the external wiring to the process

equipment is correct and that all conductors are intact.

Without activating the control equipment, you can also check that transducers and actuators

(including all process wiring) function correctly. This makes it necessary to connect voltage to

these units and develop suitable checking methods, which are time-consuming activities.

An alternative method is to make an integrated check of the process equipment and wiring and

the corresponding controller function, which can be accomplished with a circuit-by-circuit

procedure. Preferably, the controller is loaded with application data base. The data base is then

used as one checkpoint. Status/values can be read and control signals to process objects can be

simulated by an engineering station. When an operator station is included in the system, it is

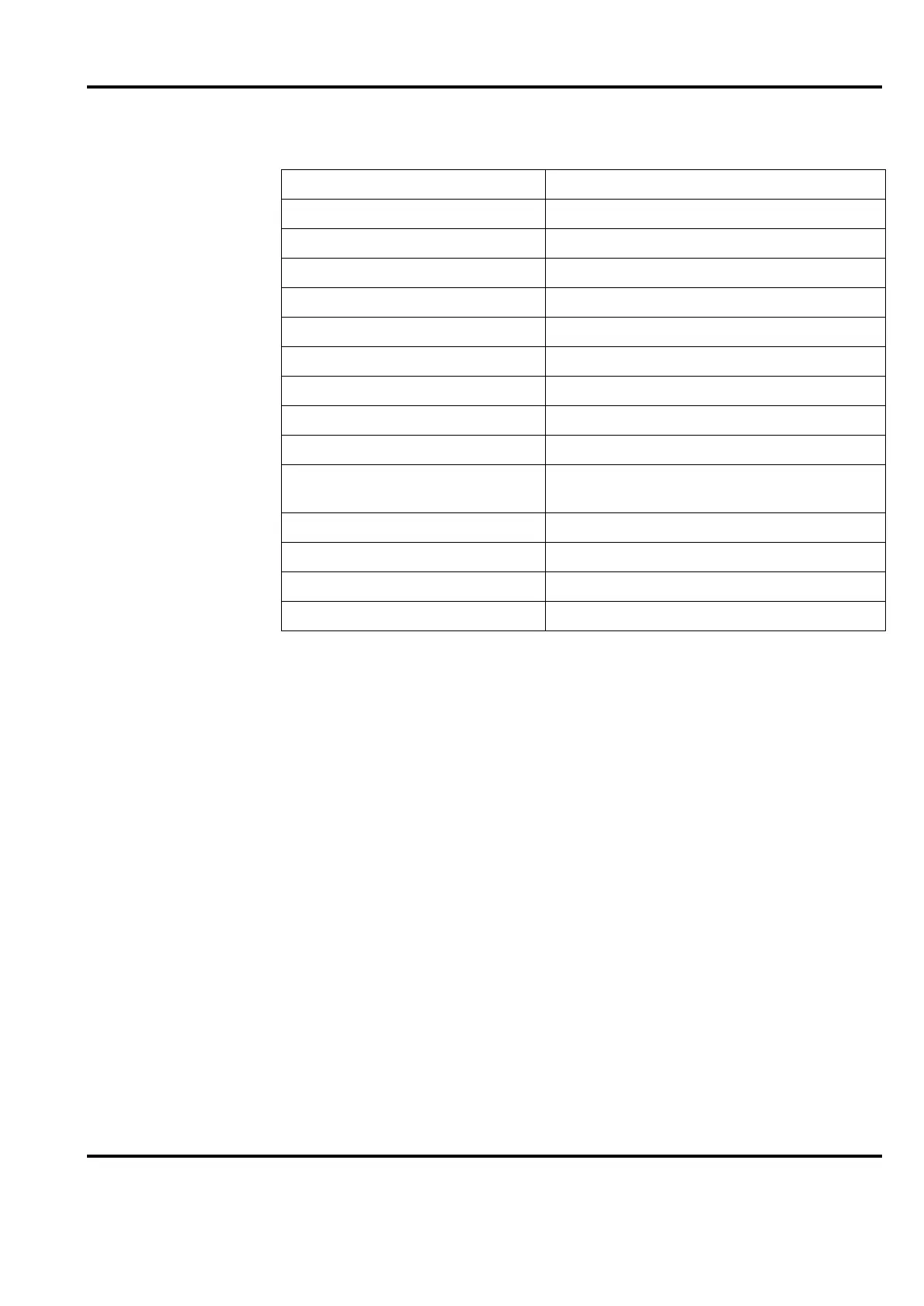

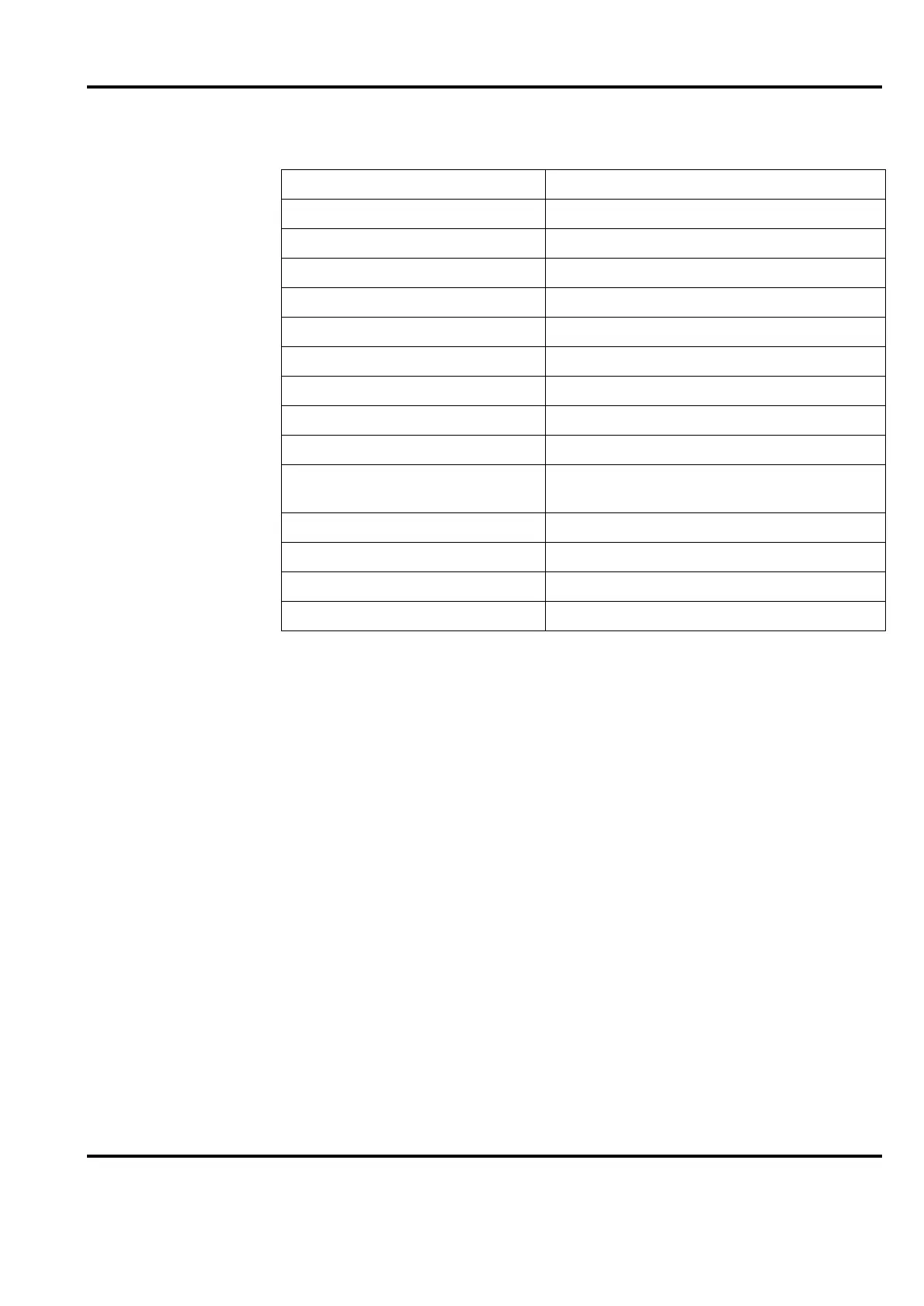

Table 2-3. Functional Jumpering

Board/Connection Unit Function

DSAI 146, 155A Mains frequency

DSTA 001, 001B, 002, 002B Current/voltage

DSTA 131, 133, 135 Current/voltage, grounded/floated supply

DSTA 155, 155P, 156, 156B Grounding

DSAO 110 Current/voltage, 10/20 mA, gain factor

DSAO 120A Current/voltage

DSAO 130 Current/voltage, 10/20 mA

DSDP 140A Filter time, function mode

DSDP 150 Function mode, voltage level

DSDP 170 Interrupt level, measuring interval source and

time, filter time for inputs

DSTX 170 Input signal level, grounding

DSDC 111 References

DSTX 110 External/internal supply

DSTY 101 Signal range

Loading...

Loading...