MAN B&W 6.04

Page 10 of 12

MAN Diesel

MAN B&W MC/MCC, ME/ME-B/MEC/MEGI-T-II engines 198 71 40-9.0

∆M

amb%

= 0.41 x (T

air

25) + 0.03 x (p

bar

1000) + 0.19 x (T

CW

25 ) 0.011 x (∆p

M

300) % [7]

∆T

amb

= 1.6 x (T

air

25) 0.01 x (p

bar

1000) +0.1 x (T

CW

25) + 0.05 x (∆p

M

300) °C [8]

where the following nomenclature is used:

∆M

amb%

: change in exhaust gas amount, in % of amount at ISO conditions

∆T

amb

: change in exhaust gas temperature, in °C compared with temperatures at ISO conditions

P

S%

= (P

S

/P

M

) x 100%

∆m

S%

= 37 x (P

S

/P

M

)

3

87 x (P

S

/P

M

)

2

+ 31 x (P

S

/P

M

) + 19

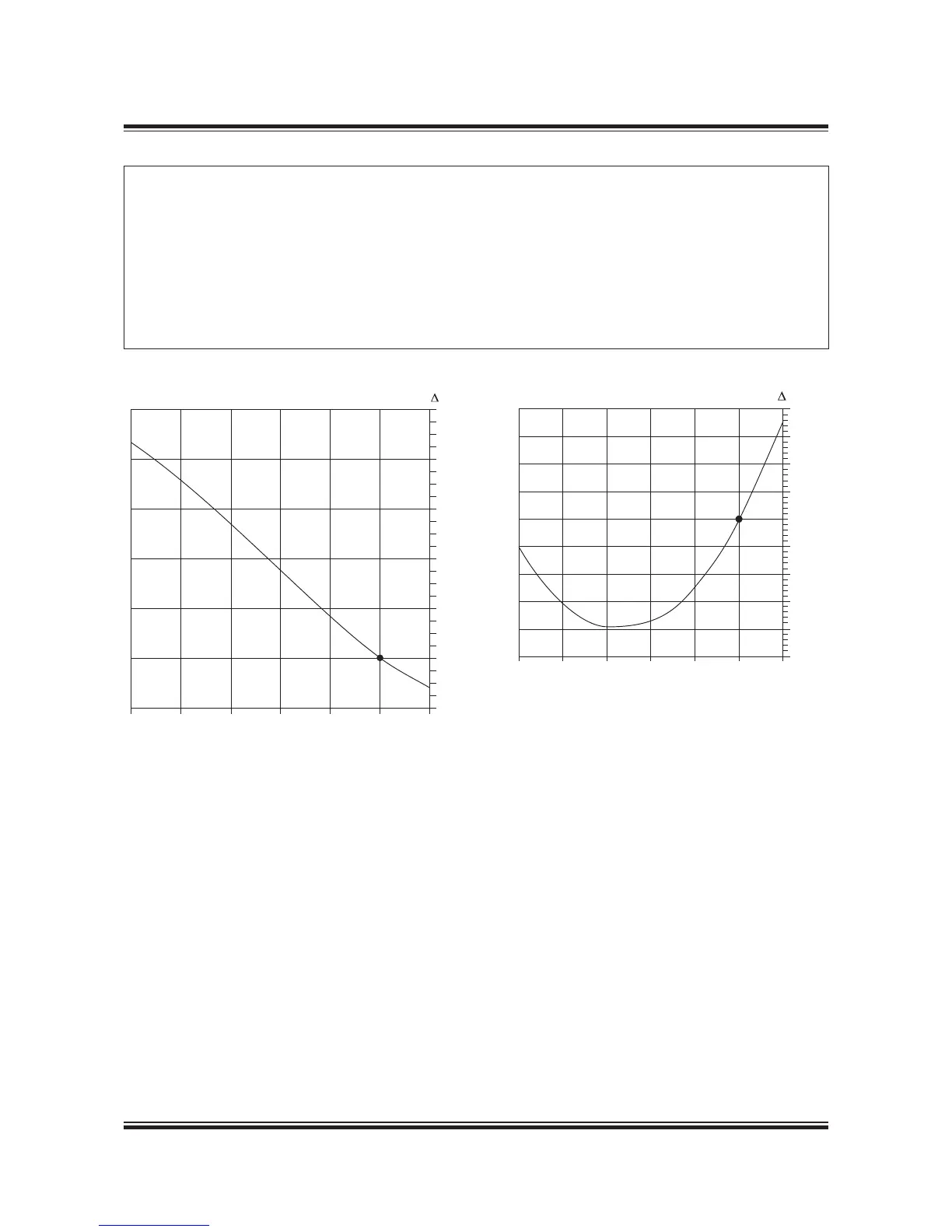

Fig. 6.04.11: Change of specific exhaust gas amount, ∆m

s%

in % at part load, and valid for FPP and CPP

P

S%

= (P

S

/P

M

) x 100%

∆T

S

= 280 x (P

S

/P

M

)

2

410 x (P

S

/P

M

) + 130

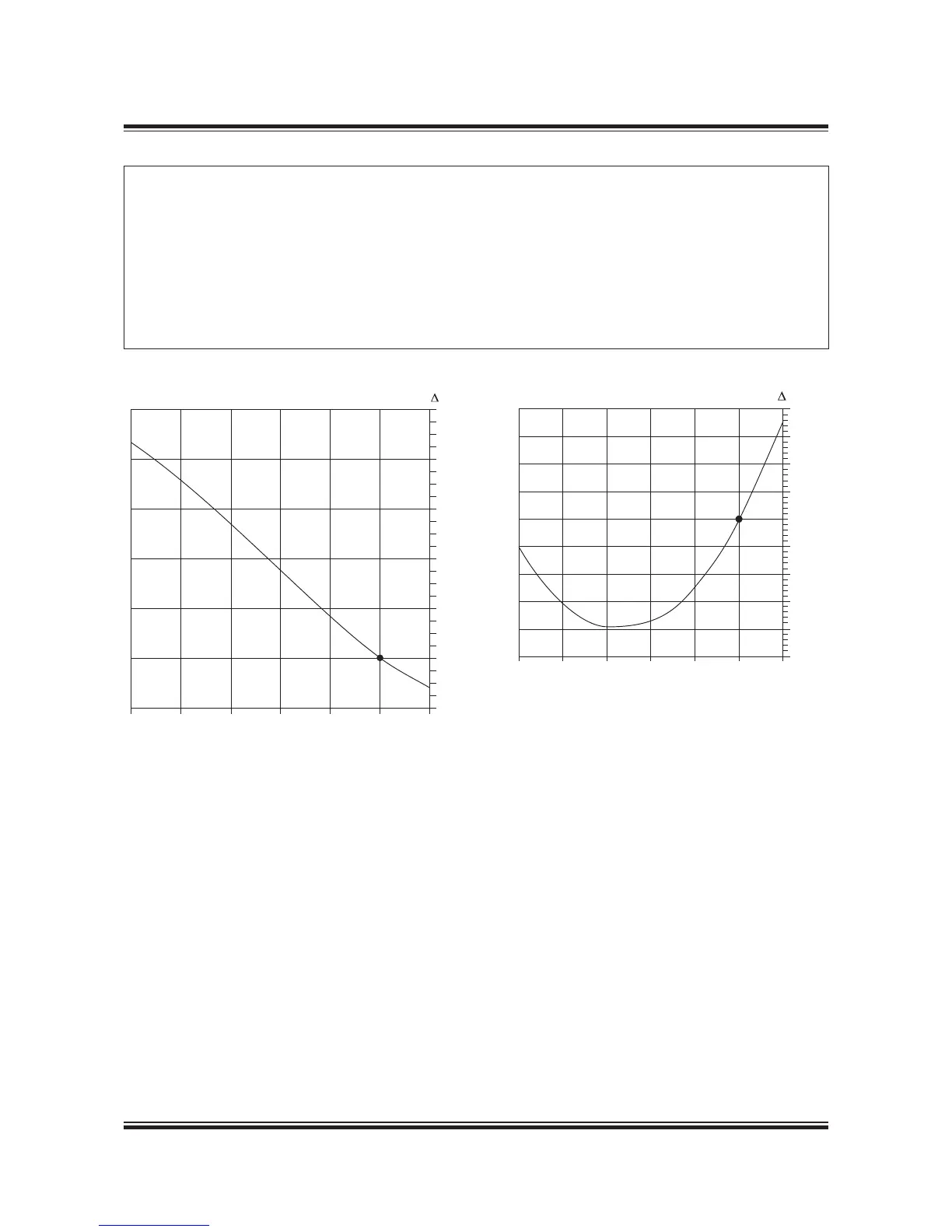

Fig. 6.04.12: Change of exhaust gas temperature, ∆T

S

in

°C at part load, and valid for FPP and CPP

178 24 623.0 178 24 635.0

c) Correction for engine load

Figs. 6.04.11 and 6.04.12 may be used, as

guidance, to determine the relative changes

in the specific exhaust gas data when running

at part load, compared to the values in the

specified MCR point, i.e. using as input P

S%

=

(P

S

/P

M

) x 100%:

∆m

s%

: change in specific exhaust gas amount,

in % of specific amount at specified MCR

point, see Fig. 6.04.11.

∆T

s

: change in exhaust gas temperature, in °C,

see Fig. 6.04.12.

16

14

20

18

12

10

8

6

4

4

2

2

0

50 60 70 80 90 100 110

P

S%

Engine load, % specified MCR power

m

S%

M

50 60 70 80 90 100 110

P

S%

Engine load, % specified MCR power

M

20

15

10

5

0

-5

-10

-15

-20

-25

T

S

°C

Fig. 6.04.10: Exhaust gas correction formula for ambient conditions and exhaust gas back pressure

Loading...

Loading...