MAN B&W 17.02

Page 1 of 3

MAN Diesel

MAN B&W S70MC/MC-C, L70MC-C, S65MC-C,

S60MC/MC-C, L60MC-C, S50MC/MC-C, S50ME-B8,

S46MC-C, S46ME-B, S42MC, S35MC, L35MC, S26MC

198 69 76-8.1

2nd Order Moments on 4, 5 and 6-cylinder Engines

The 2nd order moment acts only in the vertical

direction. Precautions need only to be considered

for 4, 5 and 6-cylinder engines in general.

Resonance with the 2nd order moment may oc-

cur in the event of hull vibrations with more than

3 nodes. Contrary to the calculation of natural

frequency with 2 and 3 nodes, the calculation of

the 4 and 5-node natural frequencies for the hull

is a rather comprehensive procedure and often

not very accurate, despite advanced calculation

methods.

A 2nd order moment compensator comprises two

counterrotating masses running at twice the en-

gine speed.

Compensator solutions

Several solutions are available to cope with the

2nd order moment, as shown in Fig. 17.03.02, out

of which the most cost efficient one can be cho-

sen in the individual case, e.g.:

1) No compensators, if considered unnecessary

on the basis of natural frequency, nodal point

and size of the 2nd order moment.

2) A compensator mounted on the aft end of the

engine, driven by the main chain drive, option:

4 31 203.

3) A compensator mounted on the fore end,

driven from the crankshaft through a separate

chain drive, option: 4 31 213.

4) Compensators on both aft and fore ends,

driven from the crankshaft by the main chain

drive and a separate chain drive respectively,

options: 4 31 203 and 4 31 213.

As standard, the compensators reduce the exter-

nal 2nd order moment to a level as for a 7-cylinder

engine or less.

Briefly speaking, solution 1) is applicable if the

node is located far from the engine, or the engine

is positioned more or less between nodes. Solu-

tion 2) or 3) should be considered where one of

the engine ends is positioned in a node or close

to it, since a compensator is inefficient in a node

or close to it and therefore superfluous. Solution

4) should be considered if the engine is positioned

over the node.

A decision regarding the vibrational aspects and

the possible use of compensators must be taken

at the contract stage. If no experience is available

from sister ships, which would be the best basis

for deciding whether compensators are necessary

or not, it is advisable to make calculations to de-

termine which of the solutions should be applied.

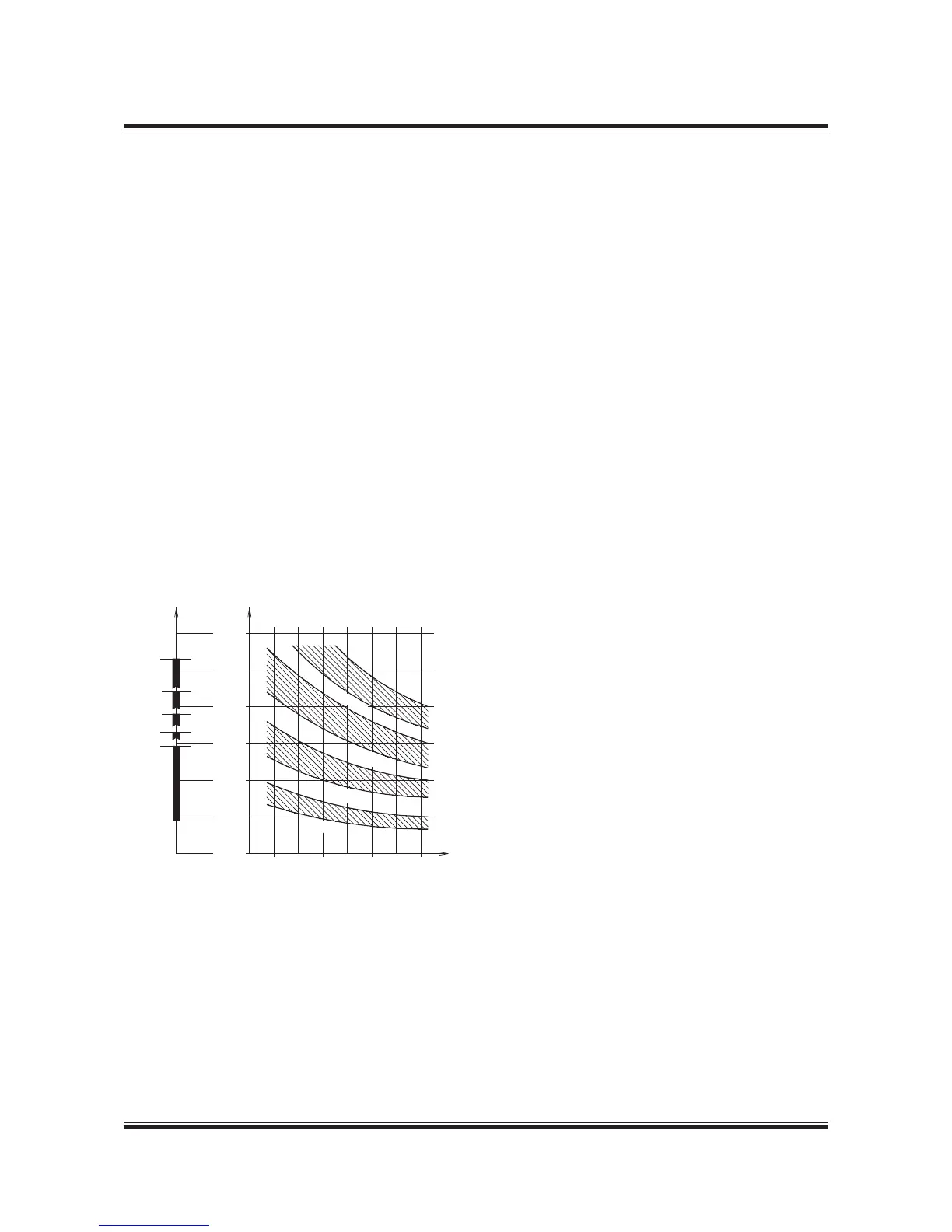

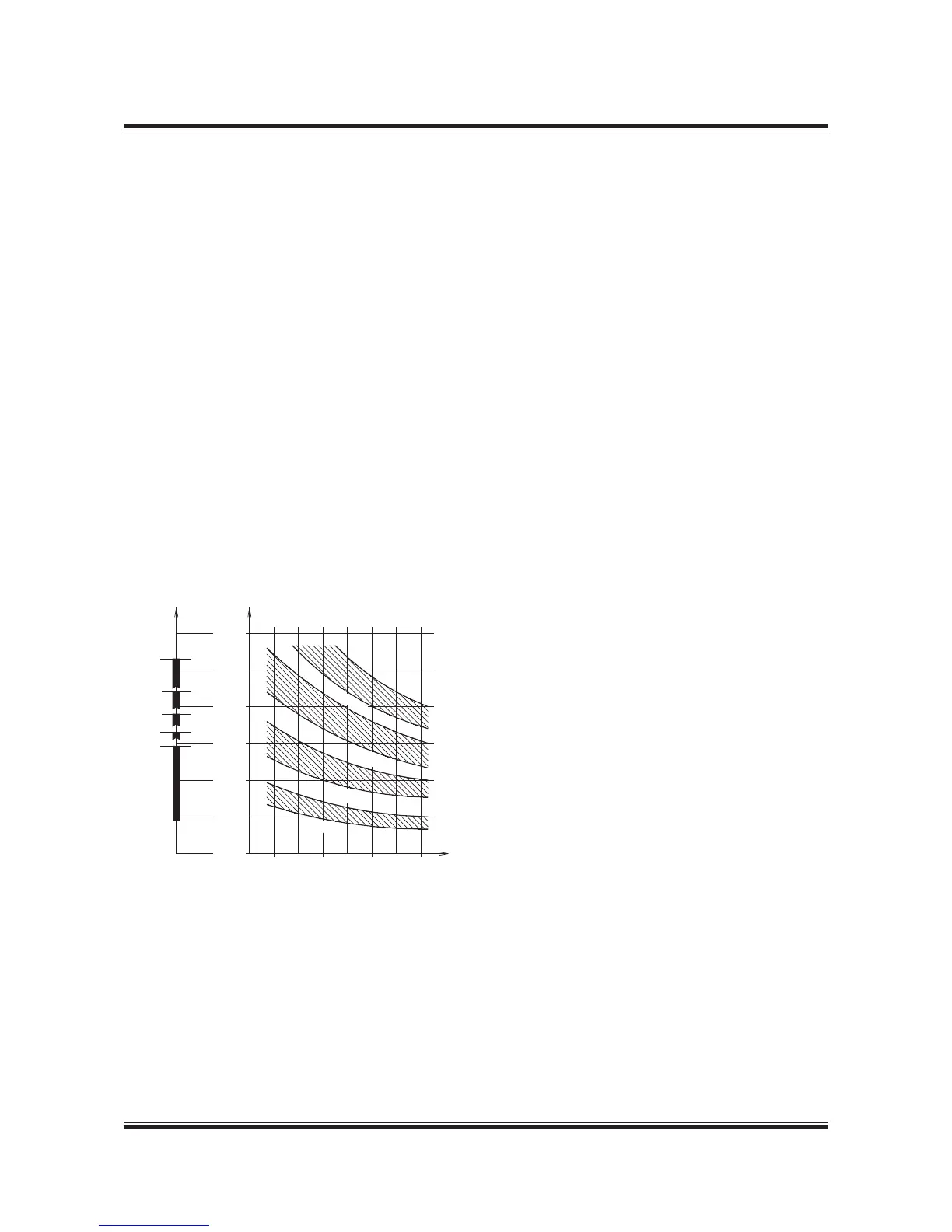

Natural frequency

cycles/min.

S50MC

S60MC

S70MC

S80MC

S90MC

150

100

50

4

n

o

d

e

3

n

o

d

e

2

n

o

d

e

20,000

40,000

60,000

dwt

80,000

200

250

300

5

n

o

de

Cycles/min. *)

*) Frequency of engine moment

M2V = 2 x engine speed

Fig. 17.02.01: Statistics of vertical hull vibrations in tank-

ers and bulk carriers

178 06 924.2

Loading...

Loading...