MAN B&W 4.01

Page 4 of 5

MAN Diesel

198 51 95-0.3MAN B&W S46MC-C7/8, S46ME-B8, S42MC7,

S40MC-C9, S40ME-B9, S35MC-C9, S35MC7,

S35ME-B9, L35MC6, S26MC6

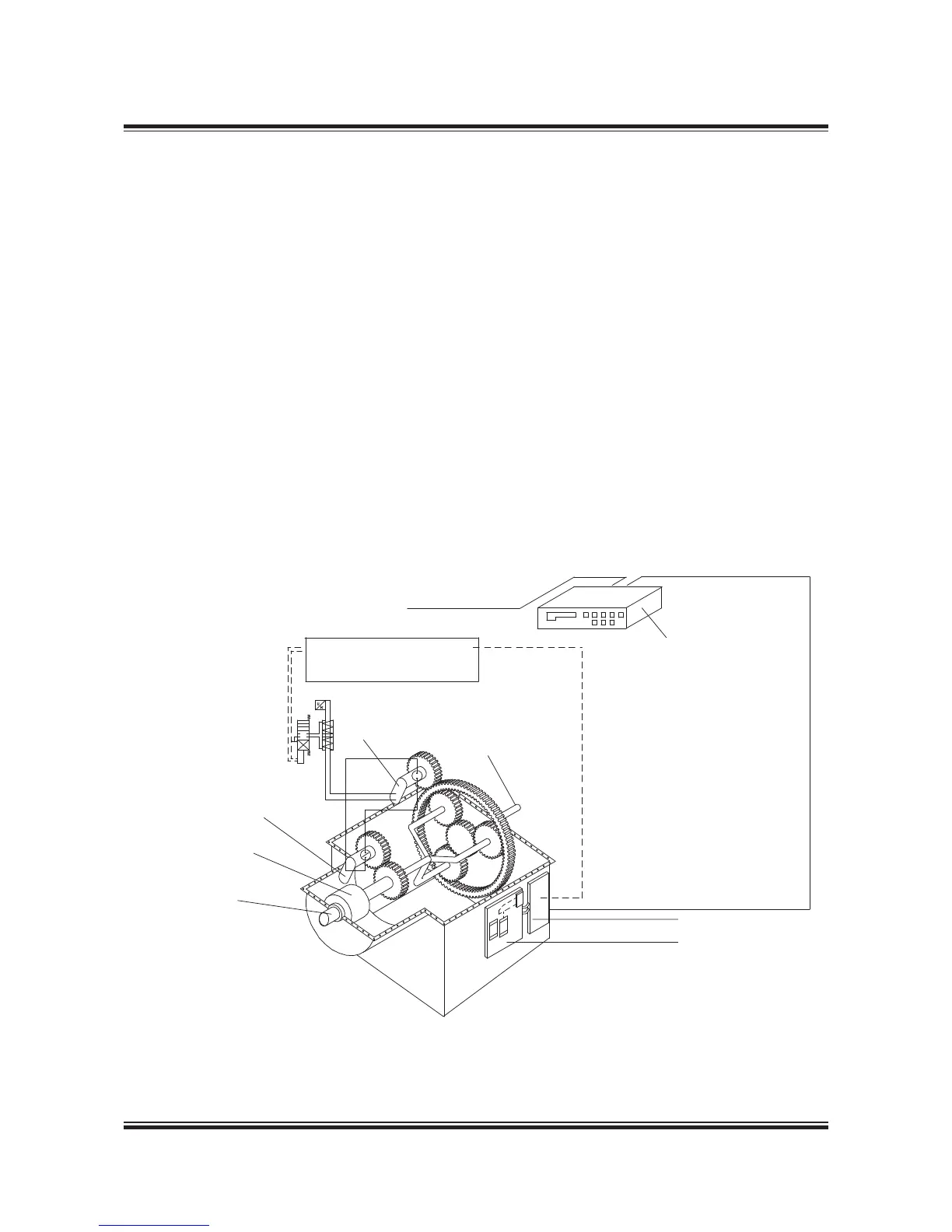

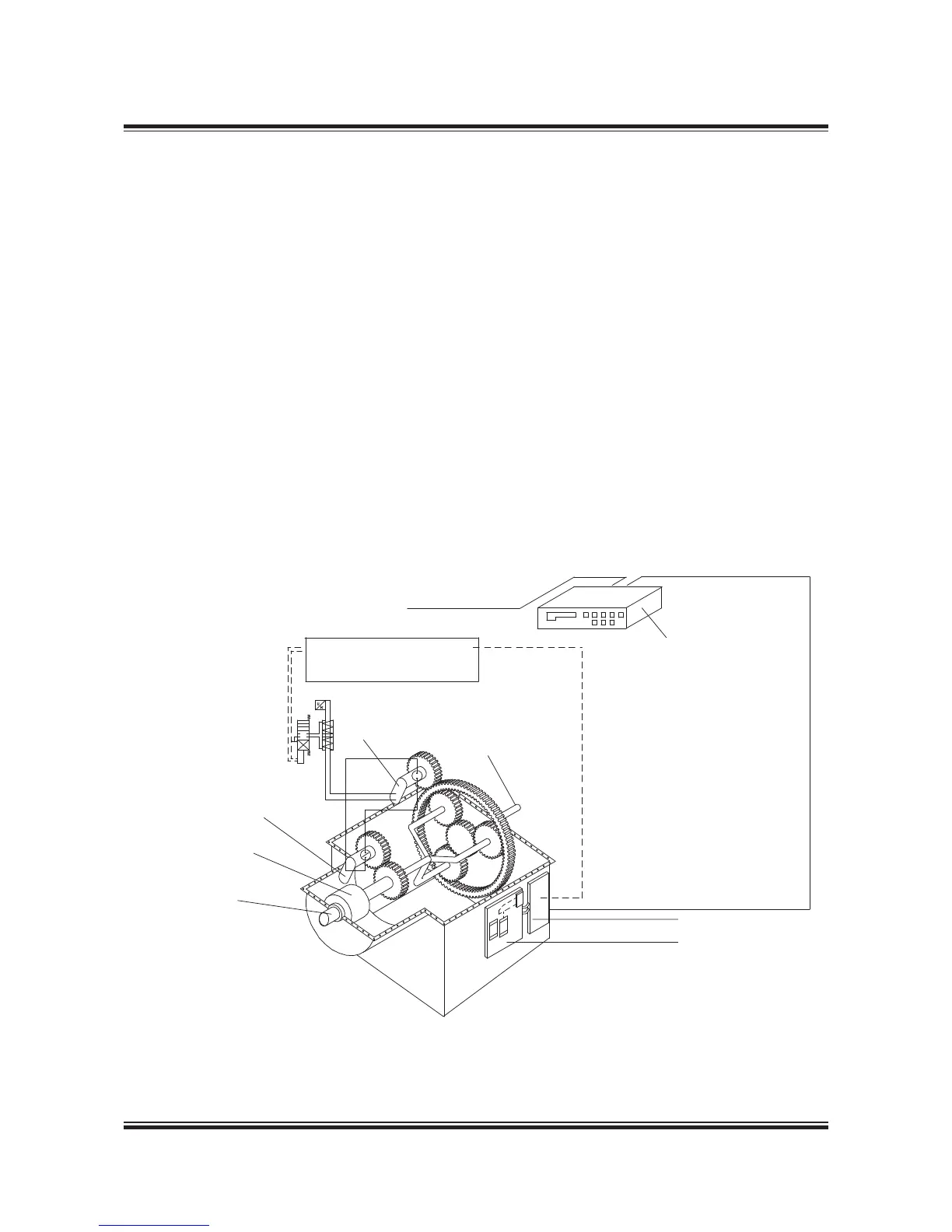

PTO/RCF

Free standing generator, BW II/RCF

(Fig. 4.01.01, alternative 2)

The PTO/RCF generator systems have been de-

veloped in close cooperation with the German

gear manufacturer RENK. A complete package

solution is offered, comprising a flexible coupling,

a step-up gear, an epicyclic, variable-ratio gear

with built-in clutch, hydraulic pump and motor,

and a standard generator.

For marine engines with controllable pitch propel-

lers running at constant engine speed, the hy-

draulic system can be dispensed with, i.e. a PTO/

GCR design is normally used, see Fig. 4.01.01,

alternative 5 or 6.

Fig. 4.01.03 shows the principles of the PTO/RCF

arrangement.

The epicyclic gear of the BW II/RCF unit has a

hydrostatic superposition drive. The hydrostatic

input drives the annulus of the epicyclic gear in

either direction of rotation, hence continuously

varying the gearing ratio to keep the genera-

tor speed constant throughout an engine speed

variation of 30%. In the standard layout, this is

between 100% and 70% of the engine speed at

specified MCR, but it can be placed in a lower

range if required.

The input power to the gear is divided into two

paths – one mechanical and the other hydrostatic

– and the epicyclic differential combines the

power of the two paths and transmits the com-

bined power to the output shaft, connected to the

generator. The gear is equipped with a hydrostatic

motor driven by a pump, and controlled by an

electronic control unit.

178 00 45-5.0

Fig. 4.01.03: PTO with RENK constant frequency gear: BW II/RCF, option: 4 85 203

Operator control panel

(in switchboard)

To panel

Hydrostatic control

Hydrostatic motor

Output shaft

Hydrostatic pump

Multidisc clutch

Input shaft

Controller

Terminal

Loading...

Loading...