MAN B&W 7.04

Page of 3

MAN Diesel

198 40 518.3MAN B&W MC/MCC, ME/ME-C/ME-GI/ME-B engines,

Engine Selection Guide

Fuel Oil Pipe Insulation

Flanges and valves

The anges and valves are to be insulated by

means of removable pads. Flange and valve pads

are made of glass cloth, minimum 400 g/m

2

,

containing mineral wool stuffed to minimum 50

kg/m

3

.

Thickness of the pads to be:

Fuel oil pipes ................................................ 20 mm

Fuel oil pipes and heating pipes together ....30 mm

The pads are to be tted so that they lap over the

pipe insulating material by the pad thickness. At

anged joints, insulating material on pipes should

not be tted closer than corresponding to the

minimum bolt length.

Mounting

Mounting of the insulation is to be carried out in

accordance with the supplier’s instructions.

Insulation of fuel oil pipes and fuel oil drain pipes

should not be carried out until the piping systems

have been subjected to the pressure tests speci-

ed and approved by the respective classication

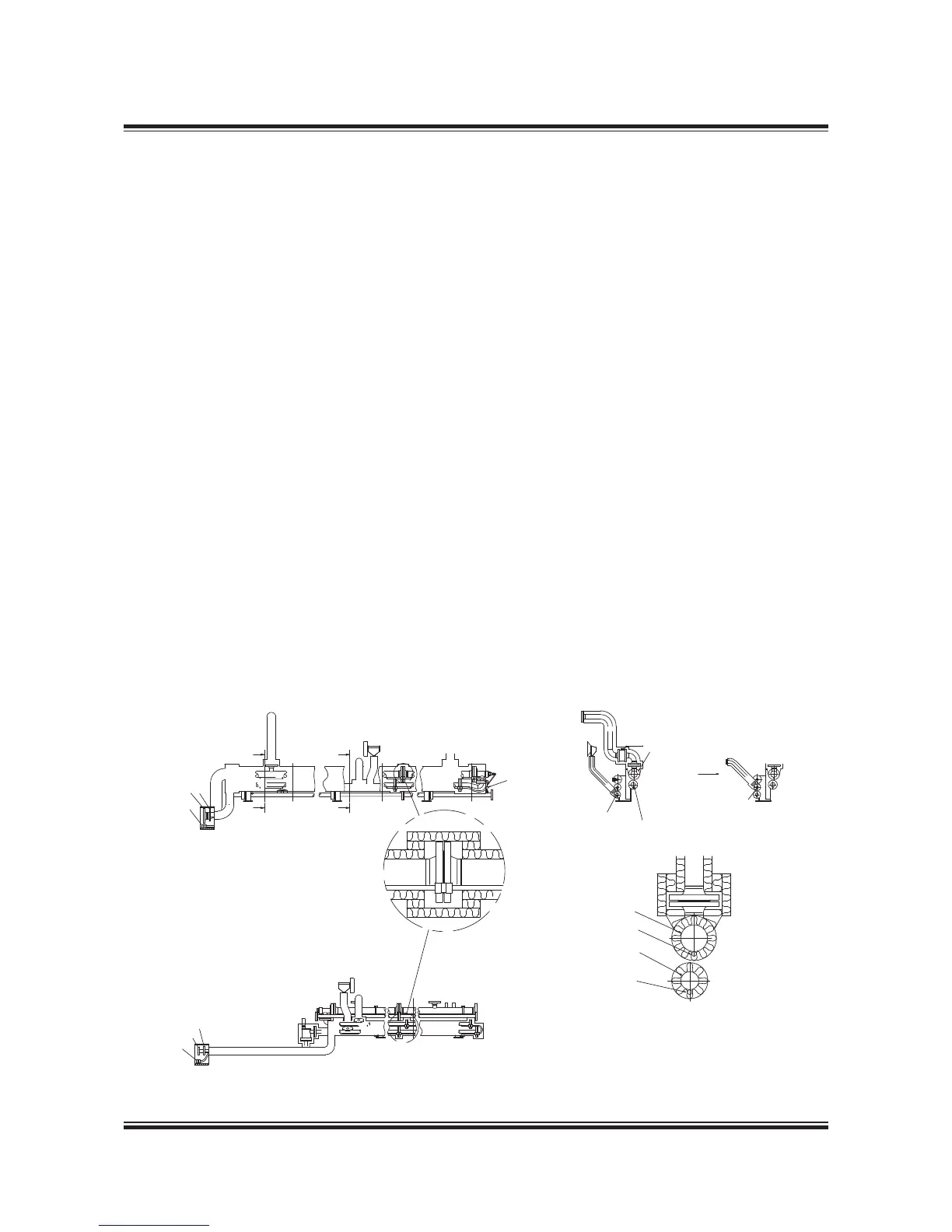

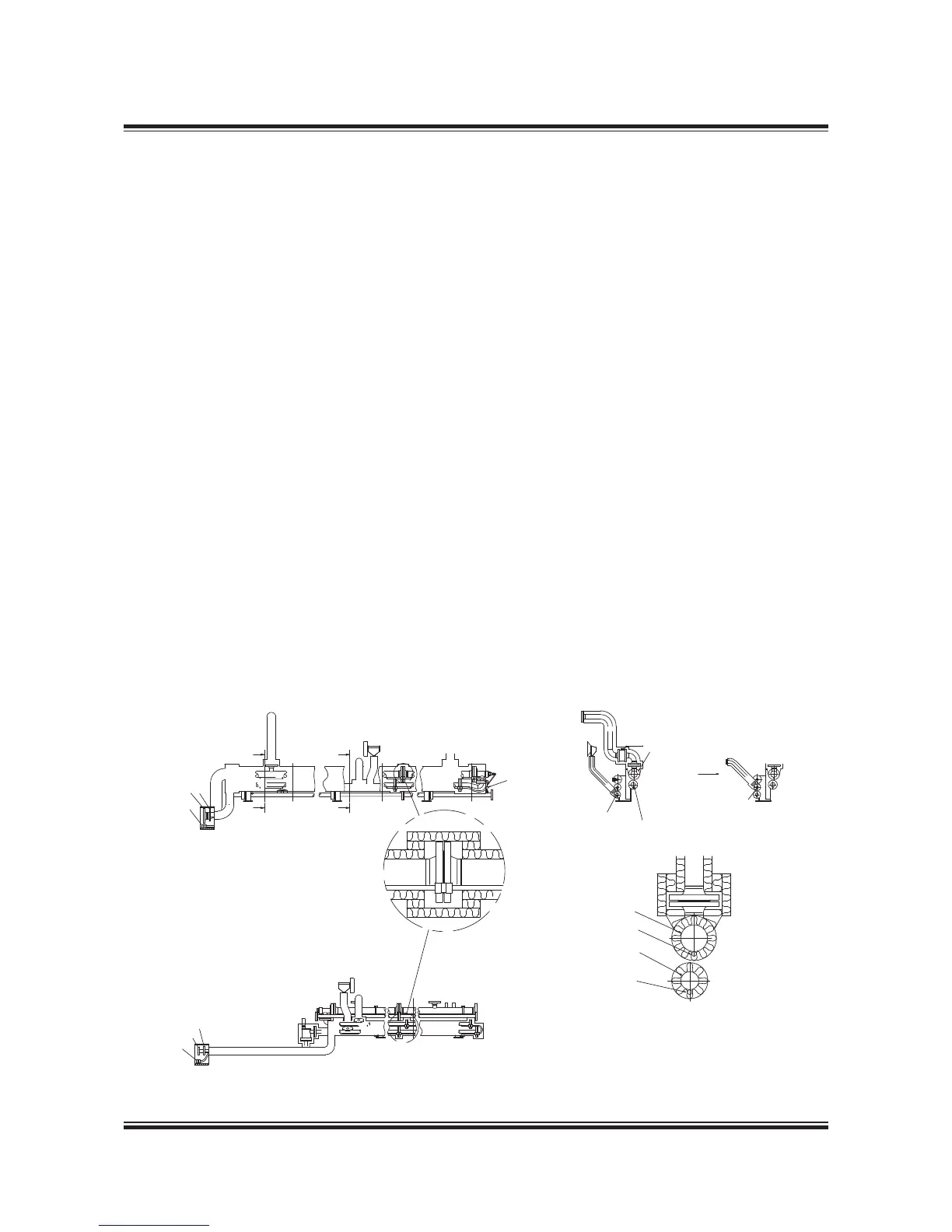

society and/or authorities, Fig. 7.04.0.

The directions mentioned below include insulation

of hot pipes, anges and valves with a surface

temperature of the complete insulation of maxi-

mum 55 °C at a room temperature of maximum 38

°C. As for the choice of material and, if required,

approval for the specic purpose, reference is

made to the respective classication society.

Fuel oil pipes

The pipes are to be insulated with 20 mm mineral

wool of minimum 50 kg/m

3

and covered with

glass cloth of minimum 400 g/m

2

.

Fuel oil pipes and heating pipes together

Two or more pipes can be insulated with 30 mm

wired mats of mineral wool of minimum 50 kg/m

3

covered with glass cloth of minimum 400 g/m

2

.

Fig. 7.04.01: Details of fuel oil pipes insulation, option: 4 35 121. Example from 98-50 MC engine

178 50 65 0.2

Loading...

Loading...