MAN B&W 4.04

Page 2 of 3

MAN Diesel

198 43 168.6MAN B&W S70MC/MC-C/ME-C/ME-GI, L70MC-C/ME-C,

S65MC-C/ME-C/ME-GI, S60MC/MC-C/ME-C/ME-GI/ME-B,

L60MC-C/ME-C, S50MC/MC-C/ME-C/ME-B, S46MC-C/ME-B,

S42MC, S40MC-C/ME-B, S/L35MC, S35MC-C/ME-B, S26MC

combinator mode. This will, however, require an

additional RENK Constant Frequency gear (Fig.

4.01.01 alternative 2) or additional electrical equip-

ment for maintaining the constant frequency of

the generated electric power.

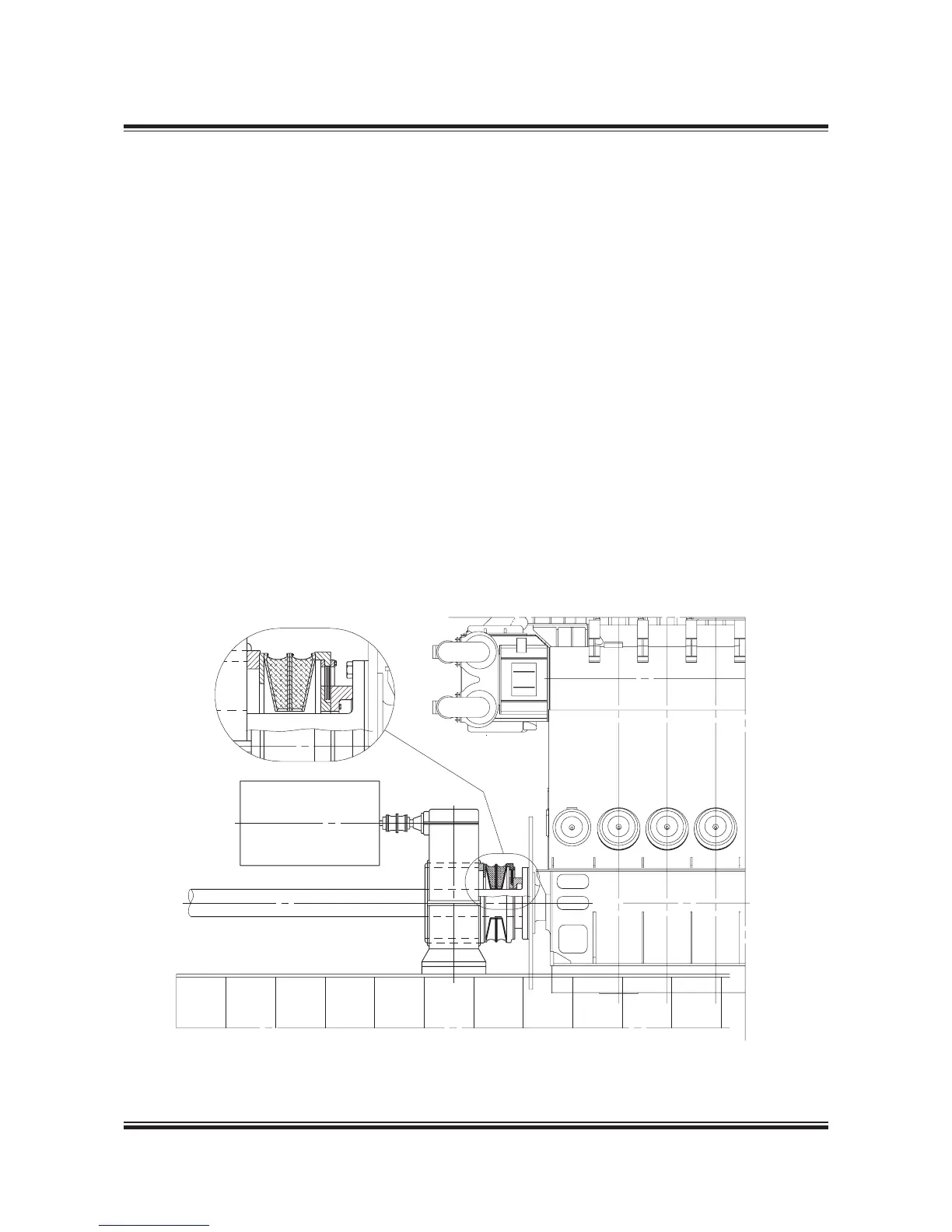

Tunnel gear with hollow flexible coupling

This PTO system is normally installed on ships

with a minor electrical power take off load com-

pared to the propulsion power, up to approxi-

mately 25% of the engine power.

The hollow flexible coupling is only to be dimensioned

for the maximum electrical load of the power take off

system and this gives an economic advantage for minor

power take off loads compared to the system with an

ordinary flexible coupling integrated in the shaft line.

The hollow flexible coupling consists of flexible

segments and connecting pieces, which allow

replacement of the coupling segments without

dismounting the shaft line, see Fig. 4.04.02.

Fig. 4.04.02: Generic outline of BW IV/GCR, tunnel gear

178 18 250.1

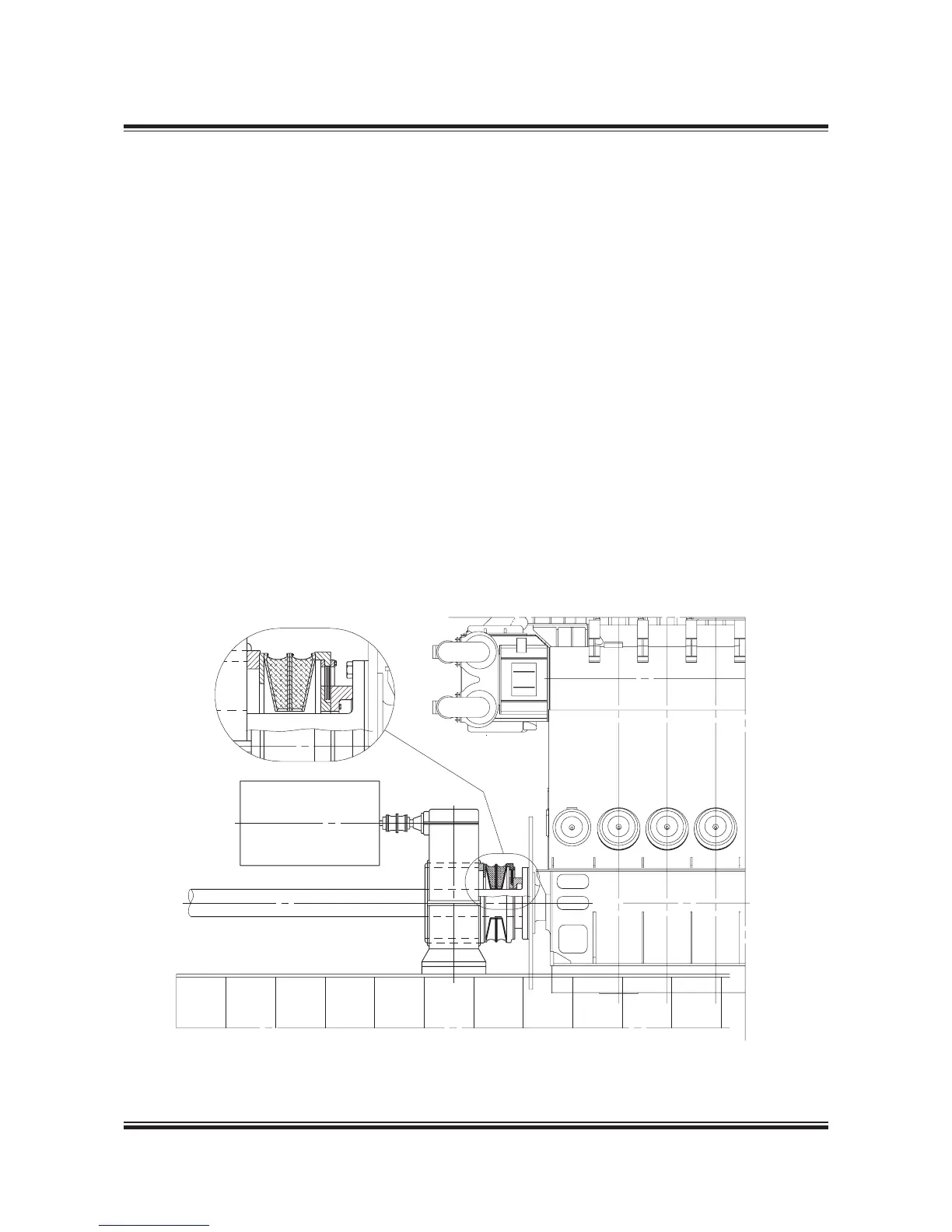

Generator stepup gear and flexible coupling

integrated in the shaft line

For higher power take off loads, a generator

stepup gear and flexible coupling integrated in

the shaft line may be chosen due to first costs of

gear and coupling.

The flexible coupling integrated in the shaft line

will transfer the total engine load for both propul-

sion and electrical power and must be dimen-

sioned accordingly.

The flexible coupling cannot transfer the thrust

from the propeller and it is, therefore, necessary

to make the gearbox with an integrated thrust

bearing.

This type of PTO system is typically installed on

ships with large electrical power consumption,

e.g. shuttle tankers.

Loading...

Loading...