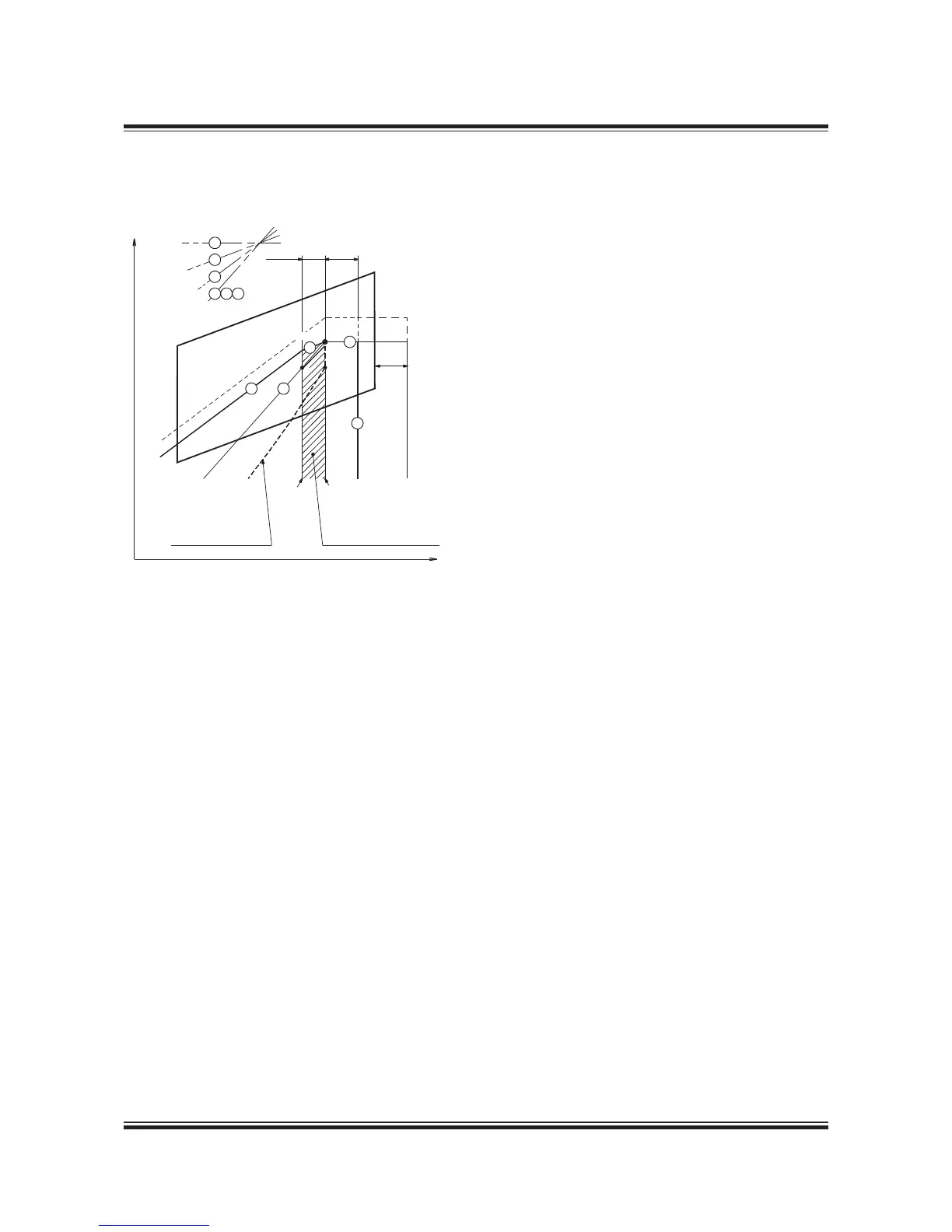

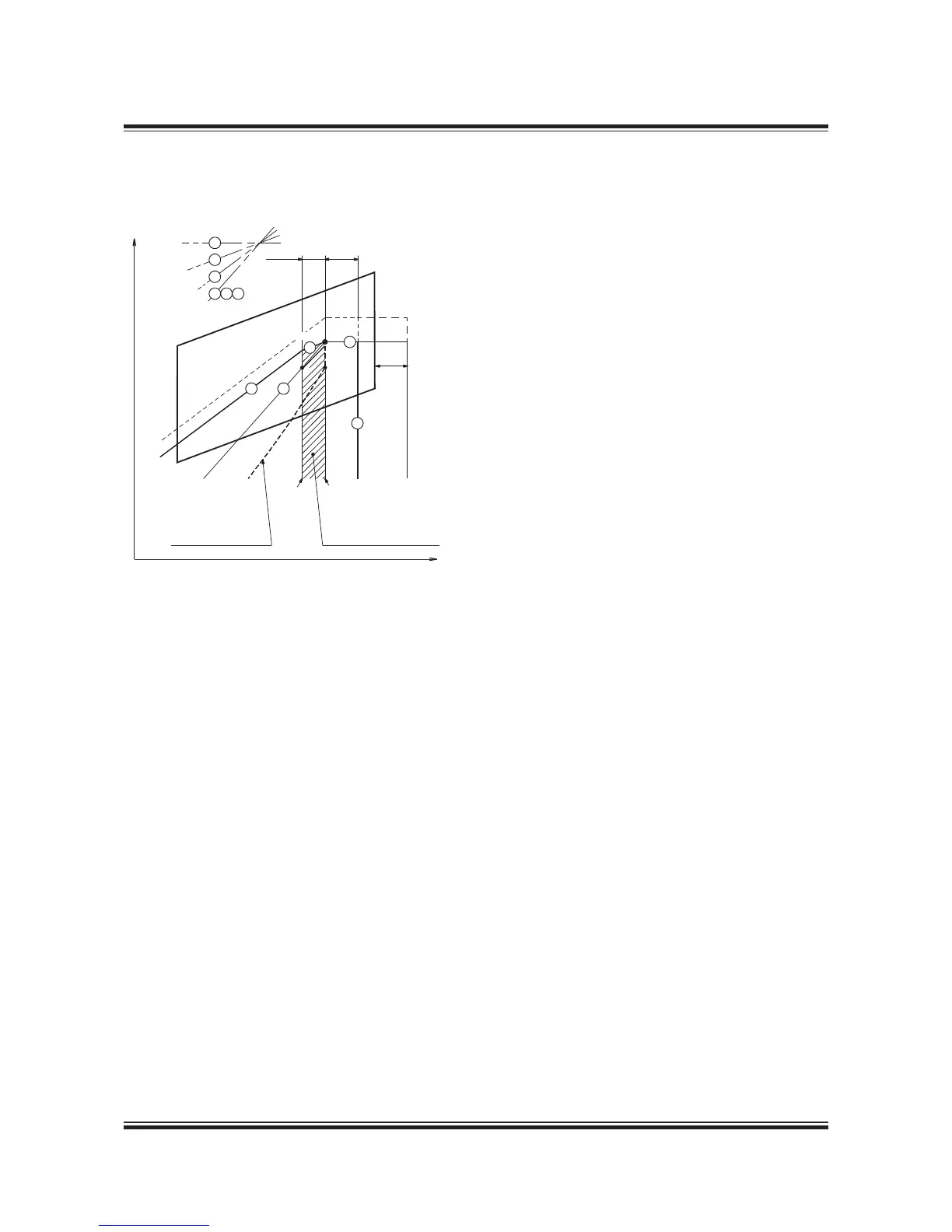

M Specified MCR of engine

S Continous service rating of engine

O Optimising point of engine

A Reference point of load diagram

178 39 31-4.4

Fig. 2.04.08: Engine with Controllable Pitch Propeller

(CPP), with or without a shaft generator

Layout diagram without shaft generator

If a controllable pitch propeller (CPP) is applied,

the combinator curve (of the propeller) will nor-

mally be selected for loaded ship, including a sea

margin.

For a given propeller speed the combinator curve

may have a given propeller pitch, and this may

be heavy running in heavy weather like for a fixed

pitch propeller.

Therefore, it is recommended to use a light run-

ning combinator curve (the dotted curve which

includes the sea power margin) as shown in the

figure to obtain an increased operation margin of

the diesel engine in heavy weather to the limit, indi-

cated by lines 4 and 5.

Layout diagram with shaft generator

The hatched area shows the recommended speed

range between 100% and 96.7% of the specified

MCR speed for an engine with a shaft generator

running at constant speed.

The service point S can be located at any point

within the hatched area.

The procedure shown in examples 3 and 4 for

engines with FPP can also be applied here for en-

gines with CPP running with a combinator curve.

The optimising point O

O may, as earlier discribed, be chosen equal to

point M, see below.

Load diagram

Therefore, when the engine’s specified MCR point

(M) has been chosen, including engine margin,

sea margin and the power for a shaft generator,

if installed, point M can be used as point A of the

load diagram, which can then be drawn.

The position of the combinator curve ensures the

maximum load range within the permitted speed

range for engine operation, and it still leaves a

reasonable margin to the limit indicated by curves

4 and 5.

Loading...

Loading...