2.32

Maintenance

Track Tension

Track tension is critical for maintaining correct suspension

operation. If the track tension is too loose, the track may

bunch-up at the rail tips, or slip (ratchet). If the track is too

tight, premature rail slide wear, reduced top speed, rear

suspension vibration can occur.

1. Lift the rear of the machine using a dedicated sled lift.

NOTE: A conventional track stand will not work for

a

djusting track tension on PRO-RIDE Progressive

suspensions as lifting the sled at the bumper will

compress the rear crank and tighten the track.

2. Start the engine and slowly let the engine turn the

tra

ck over.

3. Shut off the engine.

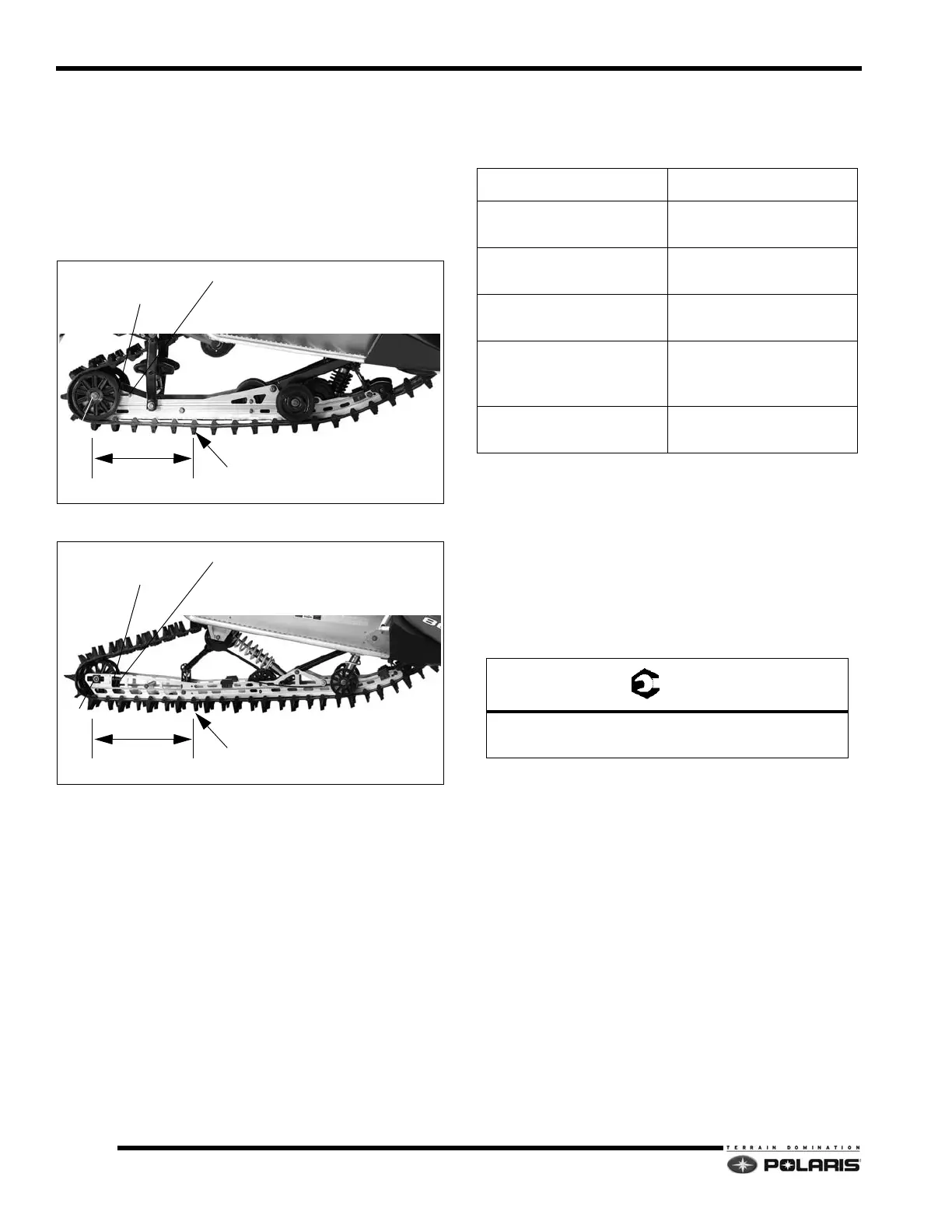

4. Place a 10 lb. (4.54kg) weight at point (A). Point (A)

is 16”

(41cm) ahead of the rear idler shaft (E).

5. Measure the distance between the rail slider and the

tr

ack. The measurement should fall within the

measurement range for the appropriate vehicle.

6. If adjustment is needed, lo

osen the jam nuts (B) on

each rail.

7. Loosen the idler shaft bolts (F).

8. Turn each adjuster screw equally (C) clockwise to

tig

hten track. Turn the adjuster screw equally

counterclockwise to loosen track tension.

9. Torque the jam nuts (B) and idler shaft bolts on each

s

ide to specification.

JAM NUT(B)

ADJUSTER SCREW(C)

10 LBS. (4.54 kg)

TRACK

A

E

F

PROGRESSIVE 120/121

16” (41CM)

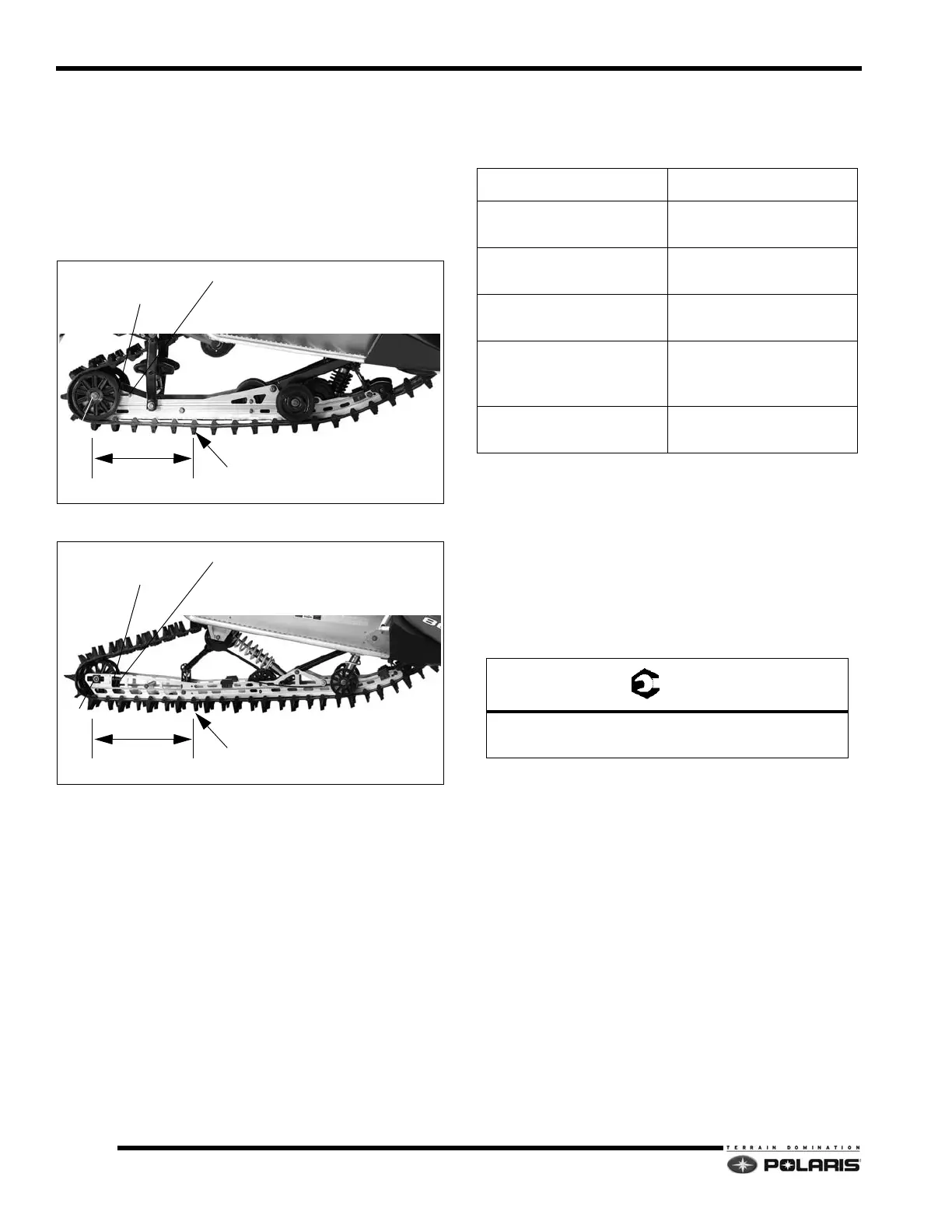

JAM NUT(B)

ADJUSTER SCREW(C)

10 LBS. (4.54 kg)

TRACK

A

E

F

16” (41CM)

SWITCHBACK 144/RMK COIL OVER

SUSPENSION MEASUREMENT

Conventional 121

(600 INDY/SP)

7/8-1-1/8

(2.2 - 2.9cm)

Progressive 120

(

2010 Rush)

7/8-1-1/8

(2.2 - 2.9cm)

Progressive 121

(2

011 Rush)

1/2- 1.0

(1.3 - 2.54cm)

Progressive 121/136

(2

012-later Rush/

Switchback)

1/4-3

/8

(6.3-9.5mm)

RMK/Switchback 144

RMK Coil Over

155/163

3/8- 1/2

(1 - 1.3cm)

Jam Nut

35 ft-lbs (47.5 Nm)

Loading...

Loading...