6.18

PVT System

Drive Clutch Disassembly

1. In a straight line, mark/etch the sheaves and the cover

with a black marker or a scribe.

2. Place the drive clutch in the clutch compression tool

(

PN 8700220).

3. Compress the clutch in the compression tool, then

secure the chain.

4. Evenly remove the cover fasteners. The cover

bu

shing may be damaged if the cover is side-loaded

or mis-aligned.

5. Carefully remove the

tension from the compression

tool.

6. Remove the cover and inspec

t the cover bushing.

Replace if damaged or worn.

NOTE: Replace the cover bushing if the inside

d

iameter is over 1.40 (28.95mm)

7. Remove the spring.

8. Mount the drive clutch securely in a drive clutch

hold

ing fixture (PN 2871358).

9. Remove the jam nut in a counterclockwise direction

(sta

ndard thread) using the drive clutch spider nut

socket (PN 2871358).

10. Install the spider removal tool (PN 2870341), and

rem

ove the spider in a counterclockwise direction

(standard thread).

11. Measure the total thickness of the spacer washers

th

at are installed on top of the clutch spacer. Record

the thickness of these spacer washers.

12. Inspect both sheave surfaces for wear or damage.

13. Inspect the moveable sheave bushing for wear or

dam

age.

14. Remove all three drive clutch weights.

15. Inspect each weight. The surface should be smooth,

w

ith no waves or galling. Place pin inside weight to

check flyweight bushing and pin surface for wear by

rocking the weight back and forth.

16. Inspect all the rollers, bushings and roller pins by

pulling a flat

metal rod across the roller.

17. Roller can also be inspected by rolling with a finger to

fe

el for flat spots, roughness, or loose bushing.

NOTE: The flyweight bushing is not replaceable. If

flyweight

bushing is damaged, the flyweight, pin and

nut will need to be replaced.

18. Inspect to see if the roller and bushing are separating.

19. Bushing must fit tightly in roller.

20. Replace roller and pin if roller fails

to roll smoothly (no

flat spots) or if the bushing is loose or worn.

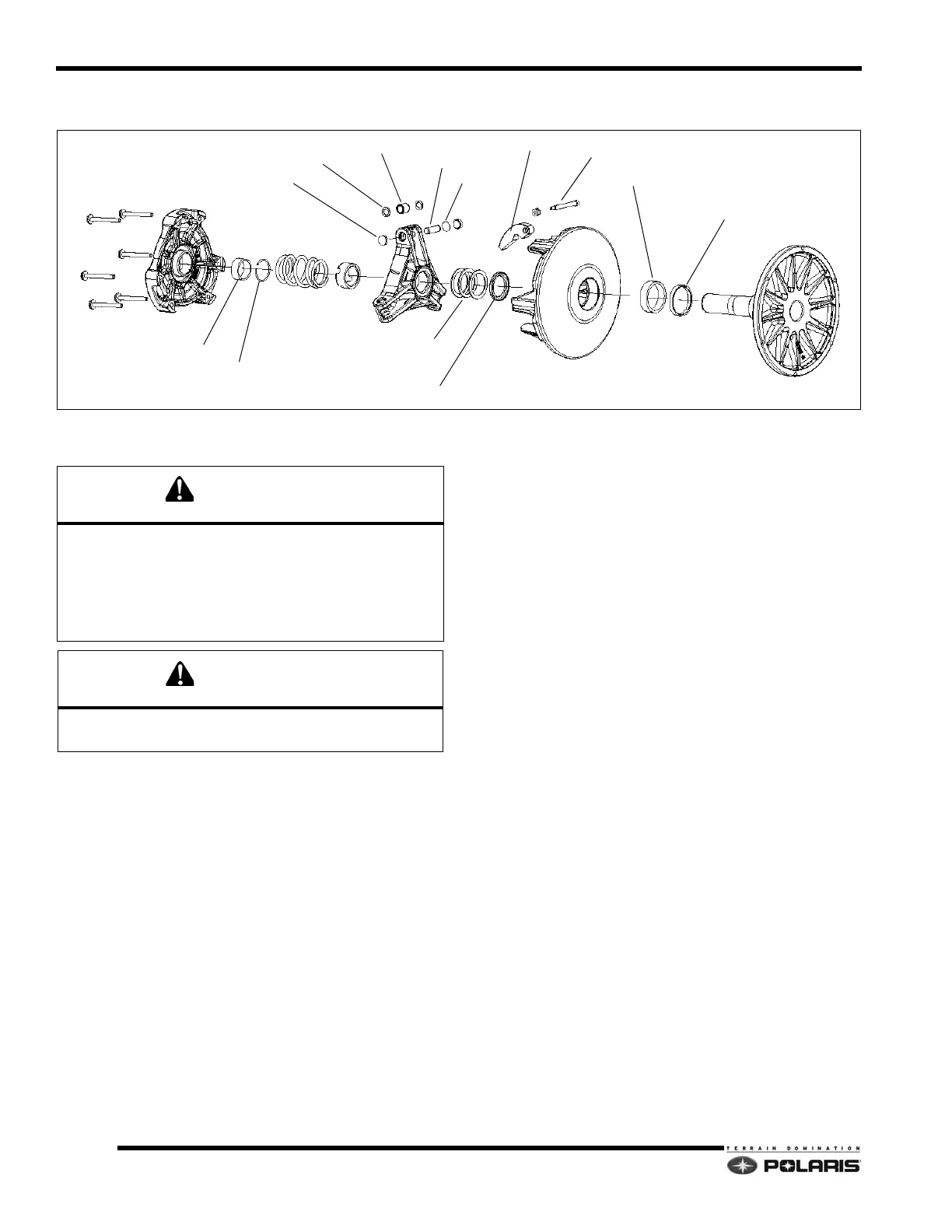

STATIONARY SHEAVE

MOVEABLE SHEAVE

SPIDER

COVER

SPRING

JAM NUT

SPACERS

CLUTCH SPACER

BEARING SLEEVE

MOVEABLE INSERT

COVER BEARING

RETAINER

SPIDER BUTTON

WASHER

ROLLER

ROLLER PIN

SHIM

WEIGHT

WEIGHT PIN

Wear eye protection when servicing the drive clutch.

Sheaves must be marked to provide a reference point

for clutch balance and spider indexing. If the sheaves

are not marked and the spider washers are changed or

misplaced, the clutch may be out of balance and

damage to the clutch may result.

Clutch spring is under extreme tension, use caution and

wear eye protection when disassembling the clutch.

Loading...

Loading...