6.24

PVT System

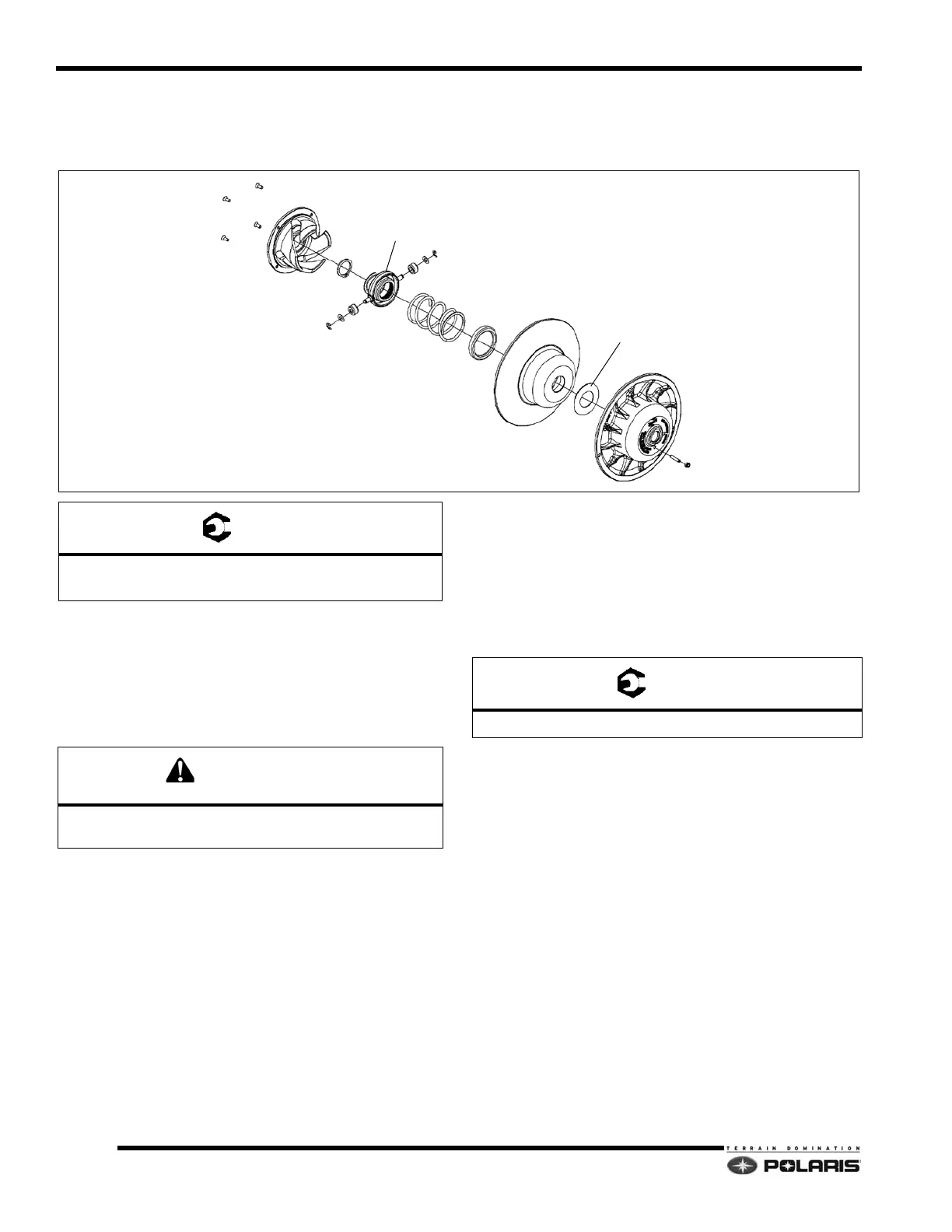

Team LWT Components

Disassembly and Assembly Process

1. Remove the screws from the helix, then carefully pry

the

helix out of the moveable sheave, or gently tap

shaft on a block of wood.

2. Install the clutch in the clutc

h compressor fixture, PN

8700220. Install the extensions, PN PS-45909.

3. Wearing eye protection, carefully compress the roller

a

ssembly to gain access to the snap ring. Remove the

snap ring.

4. Slowly release the fixture arm to remove the roller

as

sembly and spring. Disassemble the clutch

sheaves.

5. Inspect the sheaves for abnormal wear. Clean sheave

faces with

a Scotch Brite pad and a solution of warm,

soapy water.

6. Inspect spring, spring cup, spacer and rollers for wear

an

d replace as required.

7. To assemble the clutch, slide the components back on

to the sta

tionary sheave shaft.

8. Align the notch in the roller assembly with row of

dou

ble splines on the shaft. Slowly compress the

spring and roller assembly down on to the shaft. Install

the snap ring making sure it is fully seated in the

groove.

9. Install the helix by aligning the rollers with the ramps.

P

ush the helix down into the sheave while keeping the

screws holes aligned.

10. Install and torque helix fa

steners to specification.

HELIX

SNAP RING

SPRING

SPRING CUP

MOVEABLE SHEEVE

DEFLECTION SPACER

STATIONARY SHEEVE

BELT DEFLECTION SCREW

ROLLER ASSEMBLY

SCREWS

Helix Fasteners: 11 - 13 ft-lbs (15 - 17 Nm)

Driven Clutch Retaining Fastener: 17 ft-lbs (23 Nm)

Driven spring under pressure. Wear eye protection

when removing snap ring and helix.

Helix Fasteners: 11 - 13 ft-lbs (15 - 17 Nm)

Loading...

Loading...