6.26

PVT System

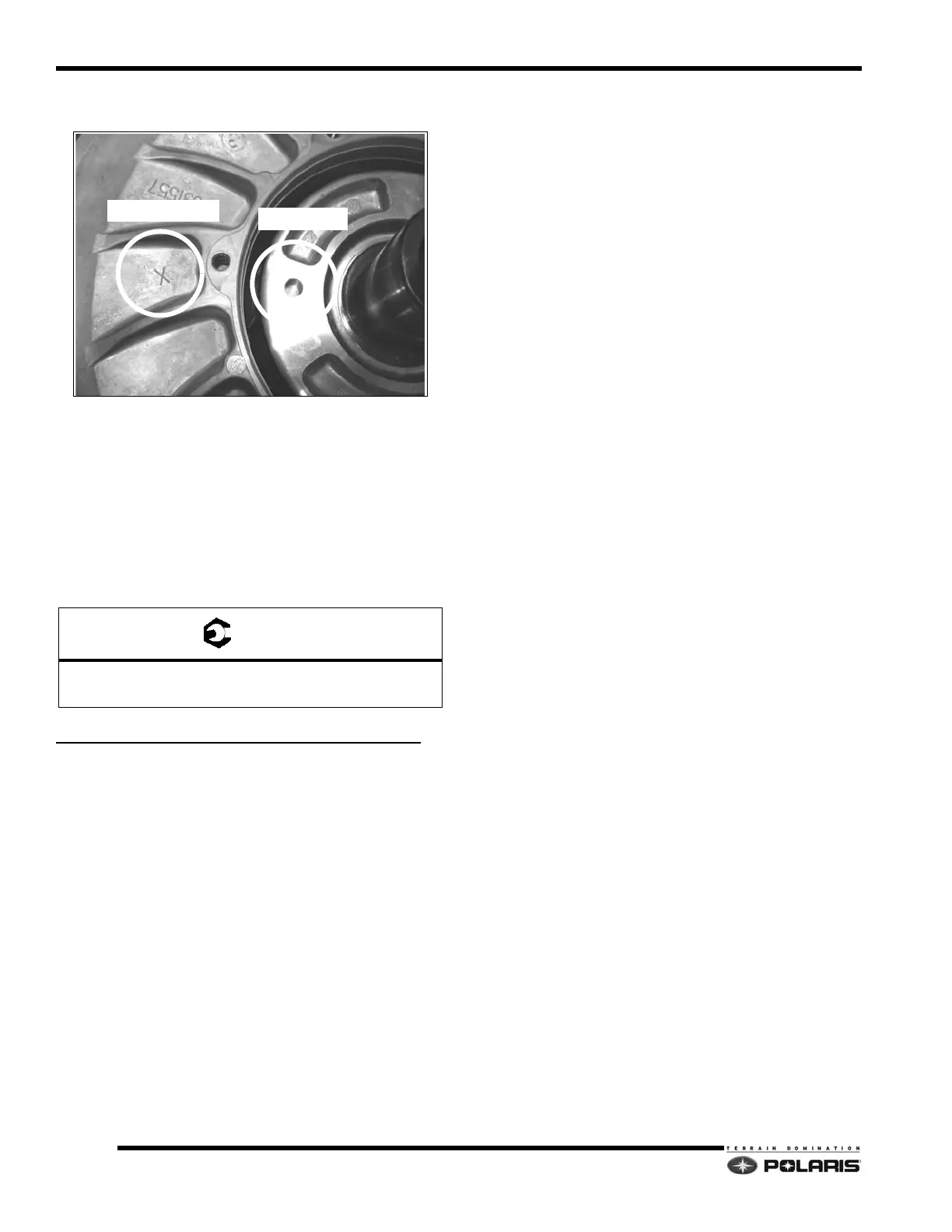

12. Align the helix alignment hole with the “X” on the

moveable sheave.

13. Align the wide gap in the helix

splines with the skip

tooth in the stationary sheave shaft.

14. Visually verify the rollers are positioned underneath

e

ach corresponding helix ramp.

15. Compress the helix down into the sheave. Install the

washe

r and snap ring. Verify the snap ring is fully

seated in the groove with the sharp edge upward.

16. Carefully release the clutch compressor.

17. Align the two “X” marks and install the cover. Torque

fastene

rs to specification.

PVT SYSTEM TROUBLESHOOTING

Drive Belt

• Verify specified drive belt is installed on vehicle.

• Drive belts have different width, angle and length

mea

surements. Reference: “Drive Belts” section

for specifications.

• Installing a non-specified drive belt of

ten requires

drive clutch spacer adjustments to achieve correct

belt-to-sheave clearance.

• Install drive belt so part number can be read from

le

ft-side of vehicle. Always install belt using the

same orientation as it was before removal.

• P

REMATURE WEAR: Ensure correct belt is

installed. Inspect belt-to-sheave clearance,

deflection, and clutch alignment.

Adjust gearing for rider type. Verify correct clutch

weight/spring

package is installed.

Change riding habits/style.

• OPER

ATING RPM DROP: Drive belts used on

snowmobiles operated at high speeds/loads

(mountain use) for extended periods of time

should be inspected for glazing at 1,000 mile

intervals.

• CO

RD POP-OUT: Inspect drive/driven clutch

alignment, motor mounts, and deflection. Set

driven clutch float.

• Remove belt during off-season storage period.

Drive Clutch

• PREMATURE WEAR:

Verify correct clutch weight/spring package is

inst

alled.

Inspect spider rollers/bushings for damage and

un

even wear.

Inspect sheave faces for premature wear. De-

gla

ze faces with 1500-2000 grit sand paper.

Verify jam nut/spider are torqued to specification.

• OPER

ATING RPM DROP:

Replace drive clutch spring and retest.

Inspect spider rollers/bushings.

Inspect/adjust belt-to-sheave clearance.

Inspect moveable/cover bushings.

Driven Clutch

• PREMATURE WEAR:

Verify correct clutch helix/spring is

installed.

Inspect rollers/bushings for damage and uneven

wear

.

Inspect sheave faces for premature wear. De-

gla

ze faces with 1500-2000 grit sand paper.

Verify driven clutch floats on jackshaft.

• OPER

ATING RPM DROP:

Replace spring and retest.

Inspect spider rollers/bushings.

Inspect moveable/cover bushings.

P2 Cover Fastener Torque:

12 ft-lbs (16 Nm)

Loading...

Loading...