5.22

Final Drive/Brake System

Brake Fluid Replacement & Bleeding

Each hydraulic brake is fitted with a bleeder valve and a

banjo bolt. The bleeder valve is a special screw, which

seals when tightened to the correct torque, but which

allows air and/or fluid to pass out through a hole in the

valve stem when loosened one turn.

NOTE: A second person is usually needed to assist in

ble

eding the brakes.

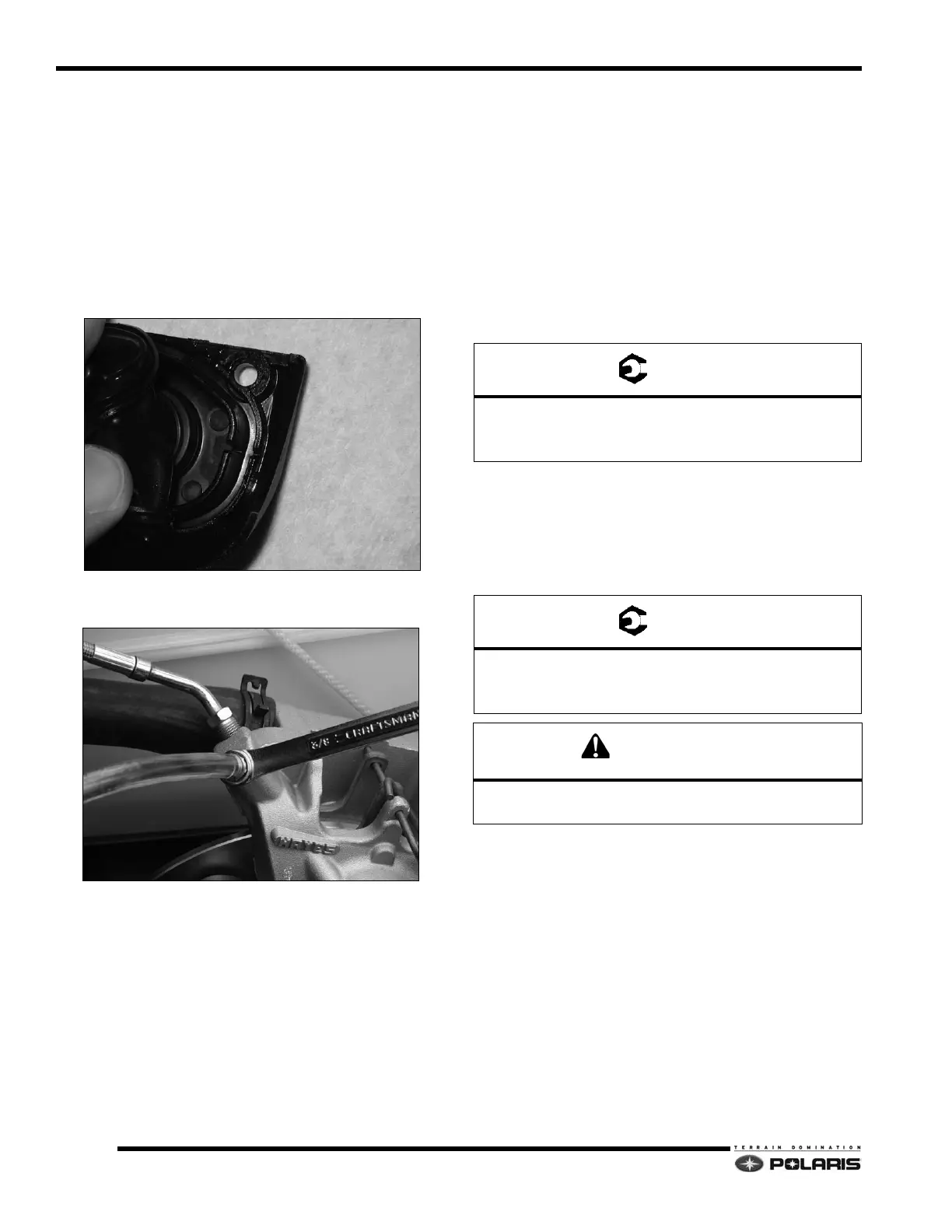

1. Clean the master cylinder cover and remove.

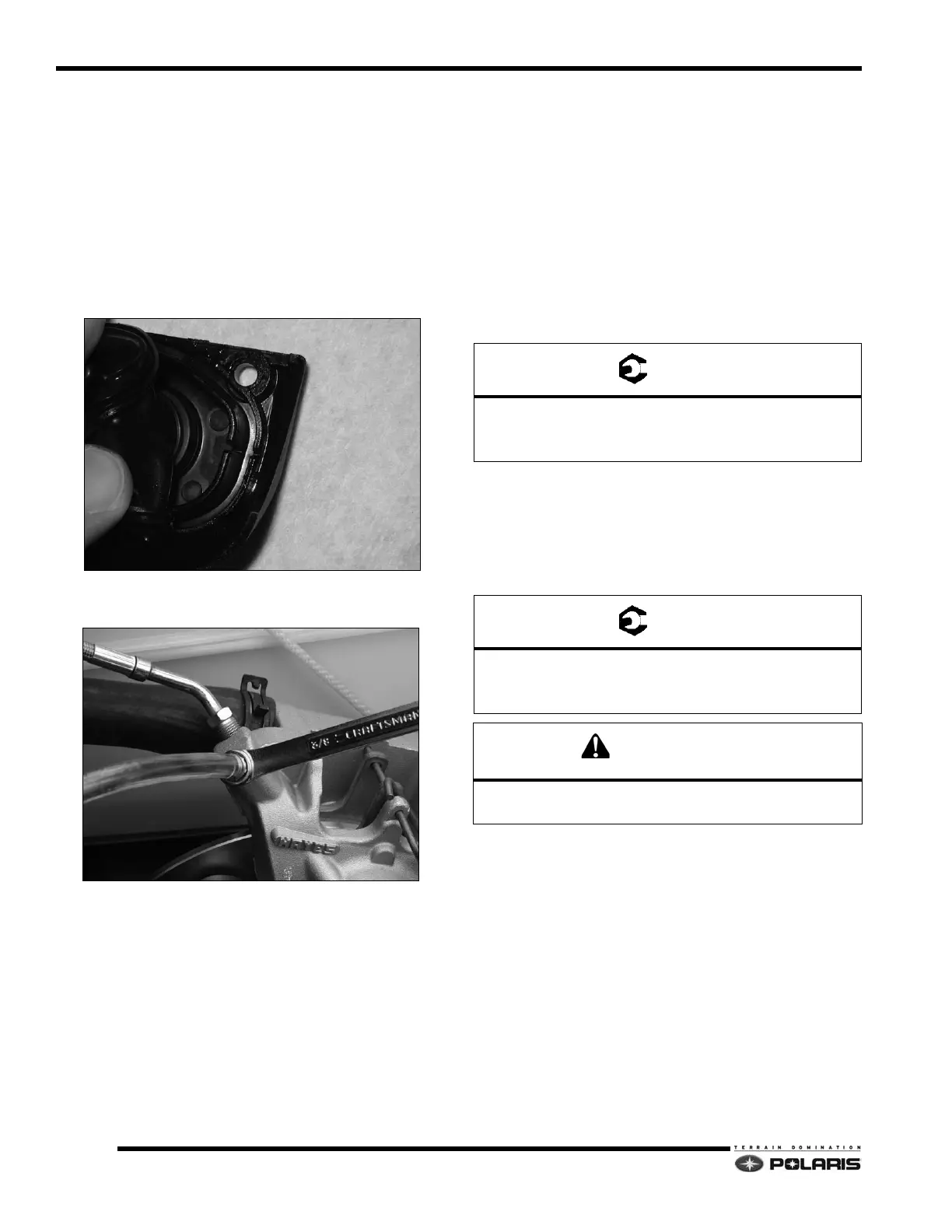

2. Attach one end of a flexible tube over the stem of the

blee

der valve.

NOTE: A 'box end' wrench placed on the bleeder

valve

before attaching the flexible tubing is a

convenient method for loosening and tightening the

bleed valve.

3. Place the other end of flexible tube into a jar

co

ntaining a small amount of clean fluid. See that the

end of the tube is below the fluid surface to prevent

breathing/sucking air back into the system.

4. Loosen bleeder valve one turn.

5. Fully apply the brake and hold, check for air bubbles

rising

in the fluid, indicating that air is being forced out

of the system.

6. Continue actuating the brake until air

bubbles stop.

This indicates that the brake has been bled

successfully.

NOTE: Add new fluid to the master cylinder reservoir

as

needed.

7. Retighten the bleeder valve when the brake lever has

re

ached the end of its stroke. Torque bleeder to

specification.

8. Evaluate the brake system for proper operation, and

inspe

ct for leaks. The brake lever should feel firm,

without excessive travel and sponginess.

9. Add new fluid to the master cylinder reservoir to bring

t

he fluid level back up to a level between the maximum

and minimum fill lines. Replace master cylinder cover.

10. Test brake system prior to returning vehicle to service.

Brake Caliper Bleeder Screws:

Phantom: 100-135 in-lbs (11-15Nm)

Phantom Lite: 36-46 in-lbs (4-5Nm)

Master Cylinder Cover Screws:

Combined: 16-20 in-lbs (1.8-2.3Nm)

Cyclone: 6-8 in-lbs (.7-.9Nm)

Caution: Take care not to get brake fluid on pads or disc.

If brake fluid gets on disc, fully clean disc with alcohol.

Loading...

Loading...