3.54

Engine/Cooling/Exhaust

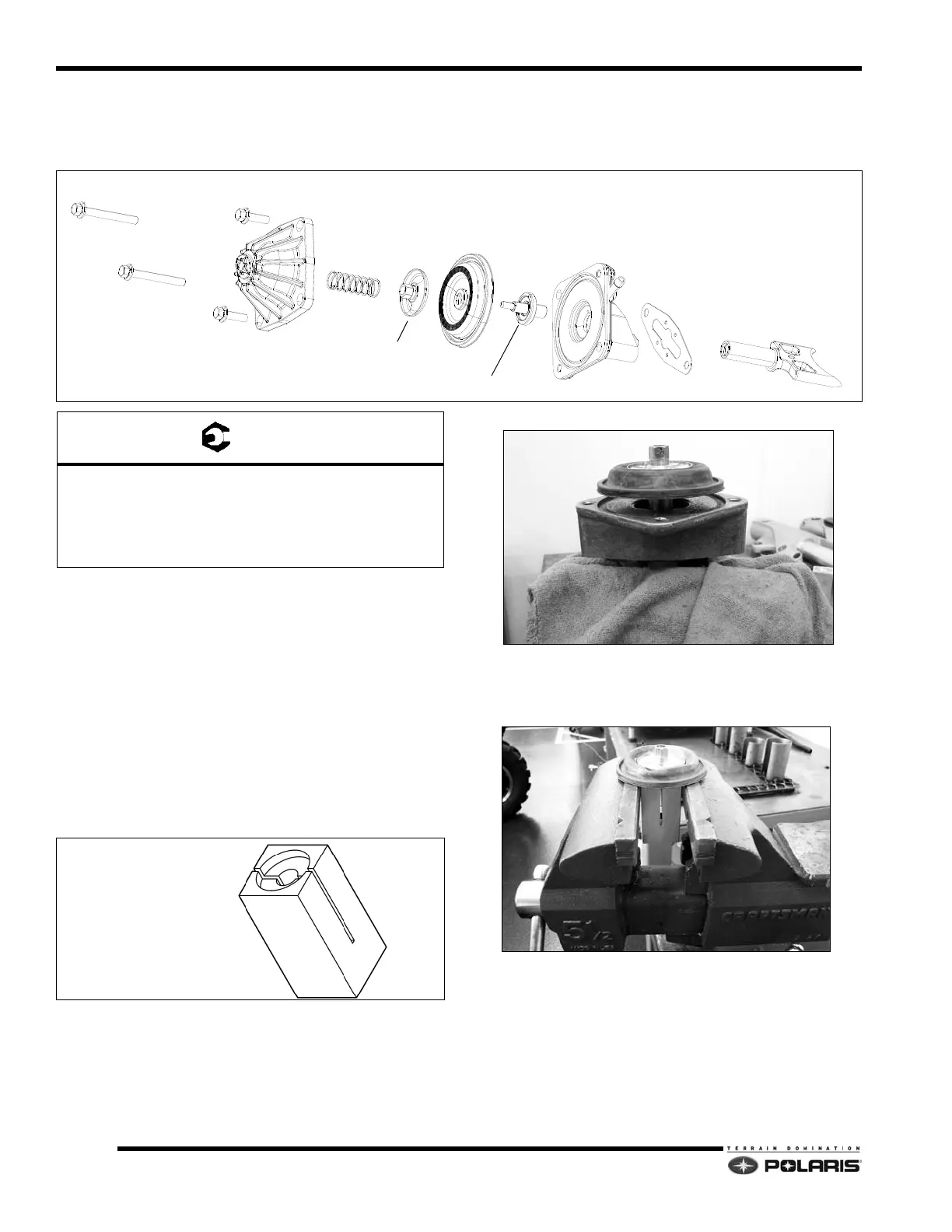

Variable Exhaust System (VES)-Threaded Stud

Assembly Notes:

• Replace spring if rusted, bent, or distorted

• Inspect bellows for tears.

• Inspect threaded stud, cap,

guillotine threads and

cap nut threads for wear/galling. Replace parts as

required.

• Discard gasket. Replace with new parts during

asse

mbly.

• Clean components as outlined in Chapter 2-

Main

tenance.

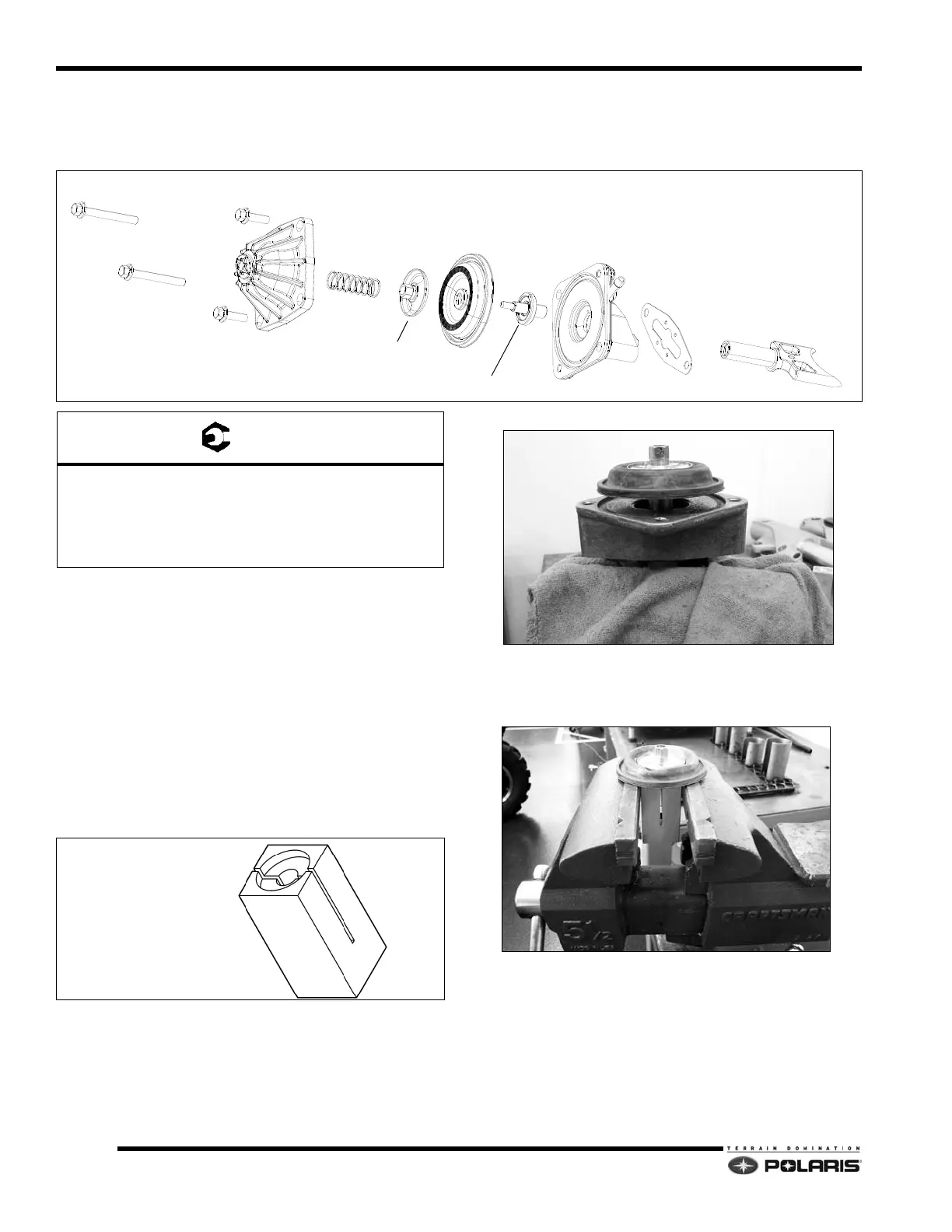

Special Tool:

Use special tool: PS-50753 to disassemble the cap nut,

b

ellows and threaded stud/washer assembly.

To disassemble guillotine component

s, clamp blade in

soft-faced bench vise. Loosen cap nut.

If the complete assembly un-s

crews from the guillotine,

use special tool PS-50753 to clamp the threaded stud/

washer in the bench vise.

During reassembly, apply Loctite® 242™ to the threaded

s

tud/washer guillotine and cap nut threads. Loosely

install the threaded stud/washer, bellows, and cap nut.

Torque only cap nut to specification to fasten all

components.

NOTE: A new threaded stud/washer has pre-applied

thr

ead lock. No Loctite® is required.

EV CAP

SPRING

CAP NUT

BELLOWS

GUILLOTINE

EV BASE

THREADED STUD/WASHER

GASKET

EV Cap Screws(A): 10.5-13.5 ft-lbs (14.3-18.3 Nm)

Apply Loctite® 242™ to cylinder screws.

Cap Nut/Threaded Stud Asm.(B): 18-22 ft-lbs

(24.5-29.9 Nm) Apply Loctite® 242™ to threaded

stu

d threads.

VES Threaded Stud/Cap Tool

PS-50573

Loading...

Loading...