7.26

Shocks

Walker Evans™ IFP Monotube Shock

Shock Disassembly

1. Remove the shock from the vehicle. Clean the shock

assemb

ly to remove all dirt and foreign material.

Inspect the assembly for any noticeable signs of

damage.

2. Clamp the body cap end of the shock in a soft-jawed

bench v

ise.

3. Remove the bleed screw from the fill port. Insert

the

needle of the gas fill tool, PN PS-45259, into the fill

port to depressurize the shock. Push the shock rod

down to ensure all nitrogen is expelled. Remove the

fill port from the body cap.

4. Remove the bearing assembly from the shock body.

Re

move the bearing assembly/shock rod from the

shock body.

5. Release the bench vise and drain all of the oil out of

th

e shock body into a suitable container. Discard the

oil in accordance with local rules and regulations.

6. Position the bearing cap end of the shock over a clean

sh

op towel on the bench. Use compressed air applied

to the fill port bore to push the IFP out of the shock

body.

NOTE: Body cap removal is only required if the

sea

ling o-ring is believed to be damaged. Final

assembly IFP depth is measured from the bearing end

of shock.

7. Remove the lock nut from the shock rod. Remove the

backup

plate, rebound stack, piston, compression

stack, and top-out plates as one assembly. Orientate

these components on a clean shop towel as they are

assembled on the shock rod.

8. Remove the shock rod from the bearing.

9. With the shock disassembled, inspect all o-rings, the

U-

cup seal, wearbands, and the wiper seal. It is

recommended that all be replaced with new parts.

10. Inspect the shock rod and shock body tube for

dam

age and/or pitting.

11. Inspect the rebound and compression stack valve

sh

ims. Shims that are damaged, bent, chipped, or

wavy in appearance must be replaced.

12. Thoroughly clean all parts and dry with compressed

air

.

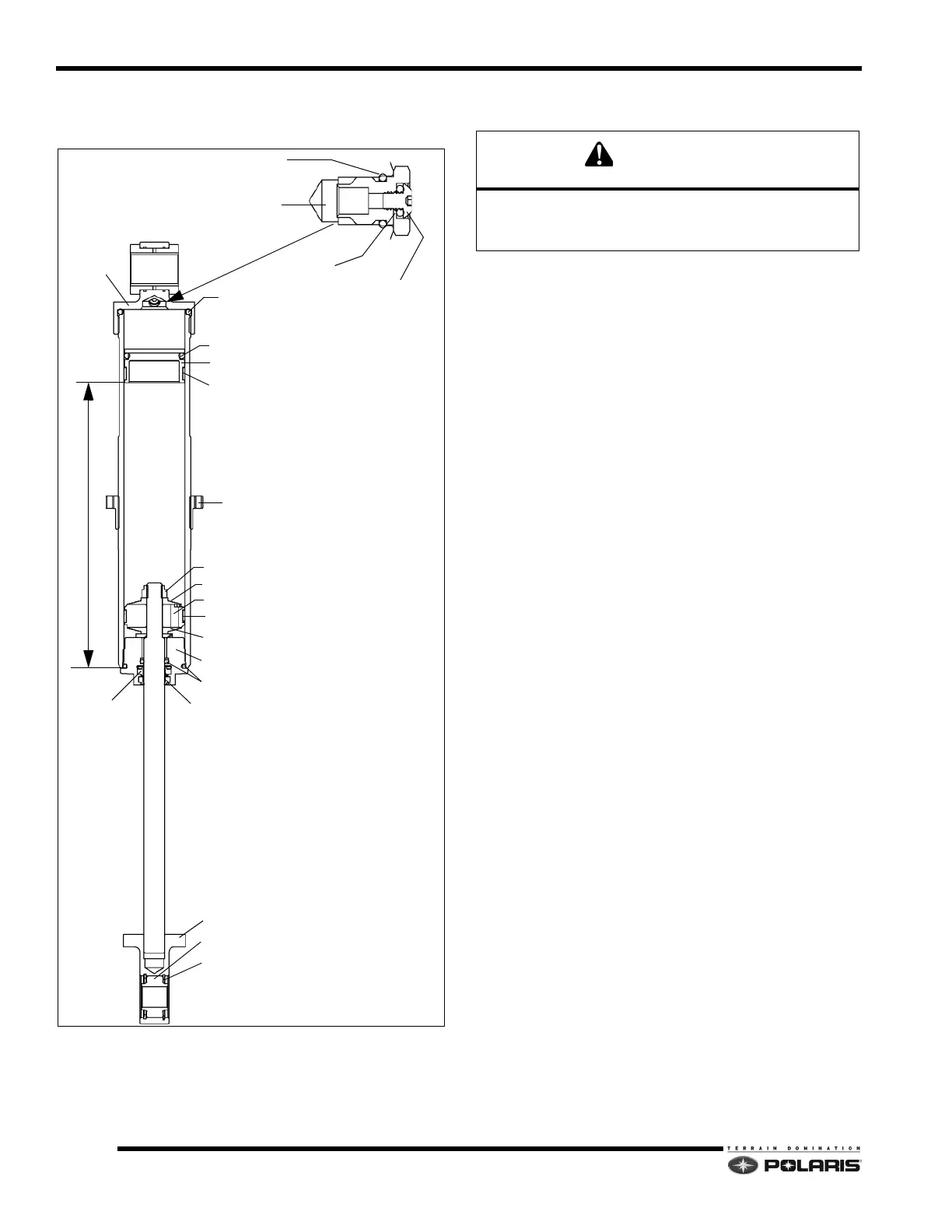

SHOCK ROD

IFP DEPTH

EYELET

O-RING

O-RING

BLEED SCREW

FILL PORT

IFP

O-RING

WEARBAND

BODY CAP

O-RING

SPRING RETAINER

LOCK NUT

REBOUND STACK

WEARBAND

PISTON VALVE

REBOUND STACK

BEARING

O-RINGS

U-CUP SEAL

WIPER

BEARING

RETAINER

SHOCK CONTENTS UNDER HIGH PRESSURE.

ALWAYS WEAR SAFETY GLASSES WHEN

WORKING WITH SHOCKS.

Loading...

Loading...