3.10

Engine/Cooling/Exhaust

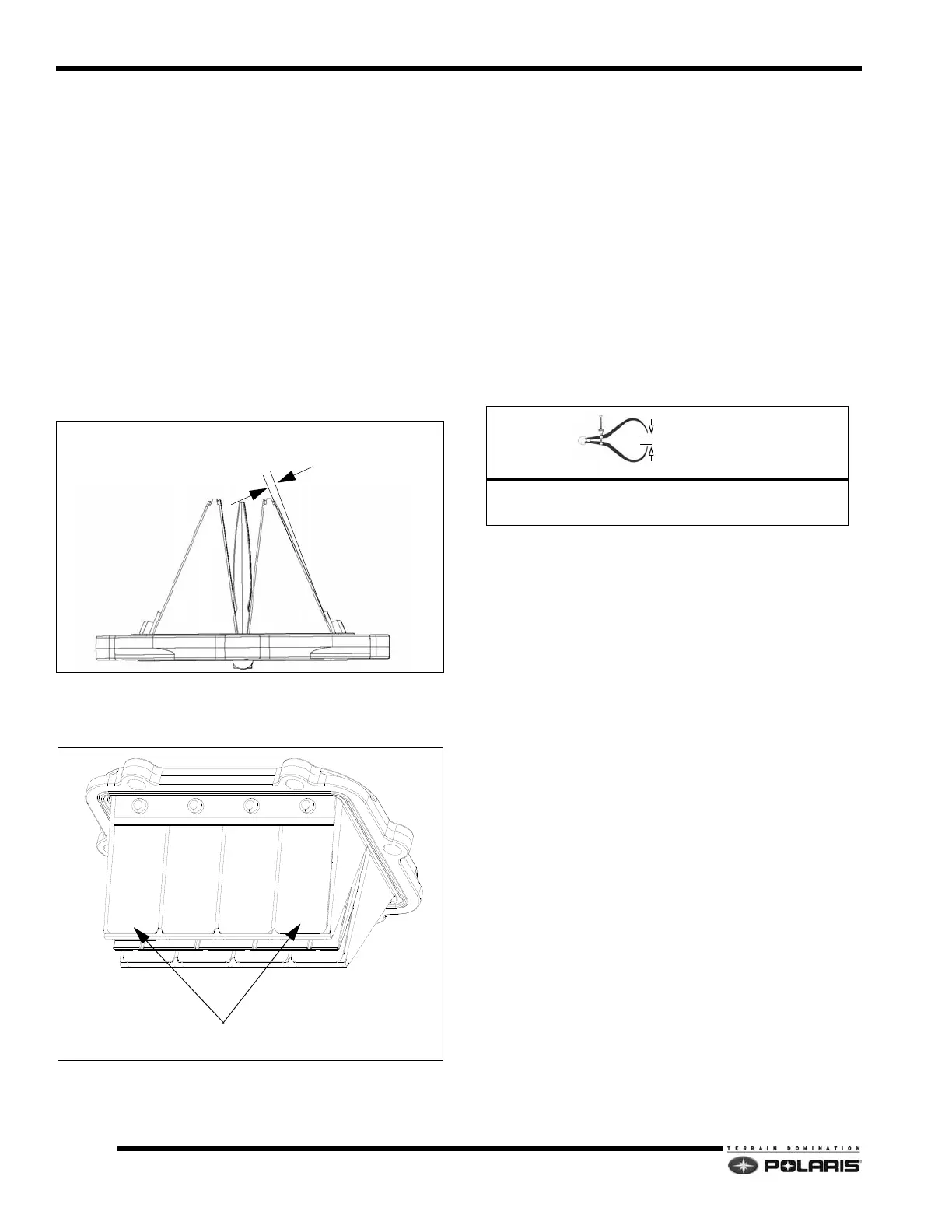

Reed Valve Inspection

1. Loosen the hose clamps.

2. Remove the throttle body

from the intake boots.

3. Remove the intake boot fasteners.

4. Remove the intake assembly.

5. Separate the intake boot from the reed cages.

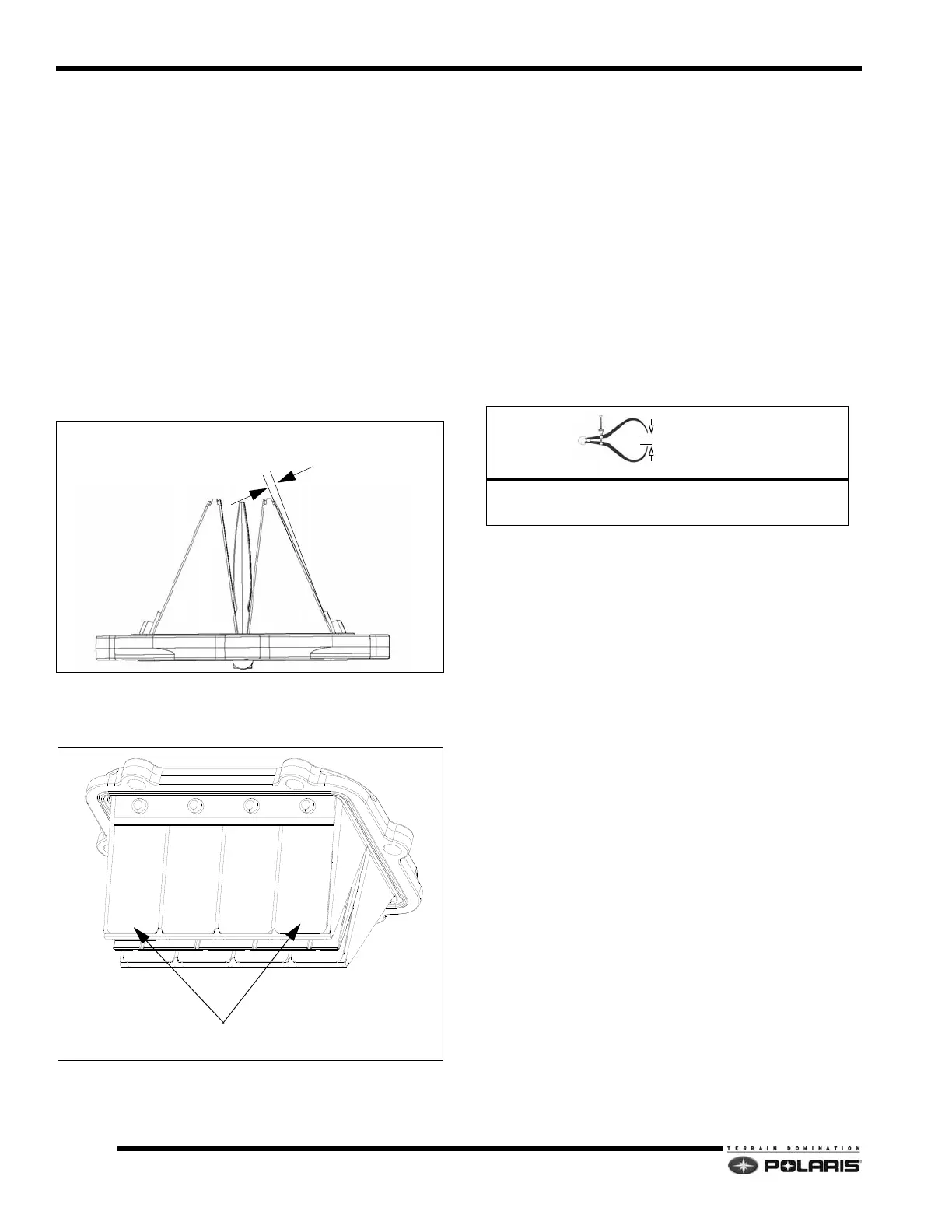

6. Separate the reed stuffer(s) from the reed cage and

in

spect the reeds before they are removed from the

reed cage.

NOTE: Measure the air gap between the fiber reed and the

reed block. The air gap should not exceed .015" (.38mm). If

clearance is excessive DO NOT attempt to reverse the reeds

to reduce the air gap. Always replace them if damaged or

worn. Check each fiber reed for white stress marks or

missing material.

7. Inspect the leading edges of each reed petal. If edges

are chipped, or excessively worn, replace the reed

assembly.

Bearing Fit

Any time crankshaft bearing failure occurs and the case is

reused, check the bearing fit into the case halves using the

following procedure.

With case halves cleaned, reins

tall the main bearings with

a piece of Plastigage between the bearing race and

crankcase.

Install and torque the crankcase fasteners to

s

pecification. Take the crankcase apart, and then

measure the Plastigage. Compare Plastigage width to

interference fit specification.

The air gap should not exceed.015” (0.30mm)

INSPECT EACH PETAL EDGE FOR DAMAGE

.061mm)

Bearing Interference Fit:

.0014" - .0024" (0.035-0.061mm)

Loading...

Loading...