4.45

Cleanfire Fuel Injection

4

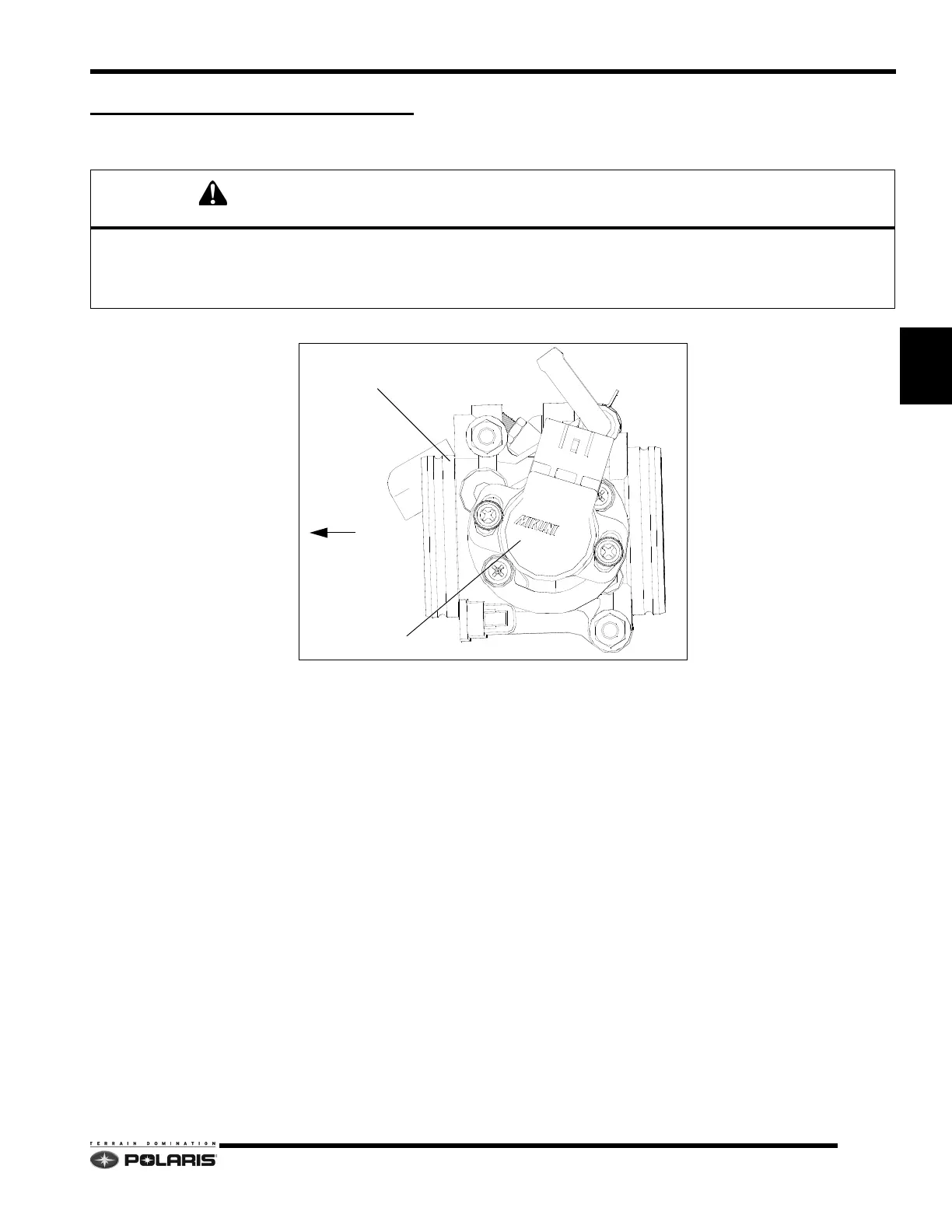

THROTTLE POSITION SENSOR

Throttle Position Sensor (TPS) Overview

The Throttle Position Sensor (TPS) is a 5 VDC potentiometer (variable resistance) type sensor mounted to the PTO side

of the throttle body. The internal components of the sensor are connected to the throttle shaft. The TPS output signal

changes as the throttle plates are opened and closed by the operator. The ECU uses this signal to determine the position

of the throttle plates.

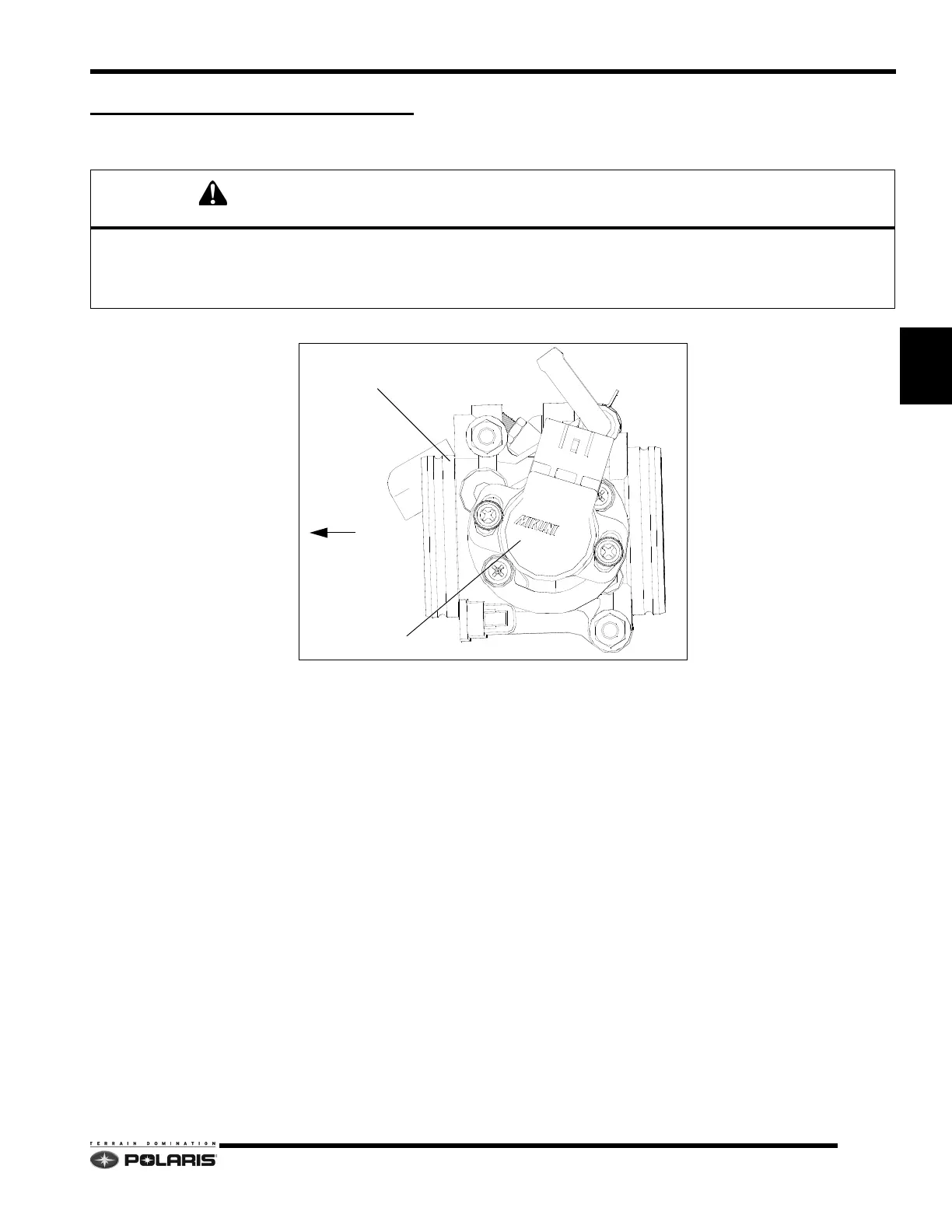

The TPS is set at the factory based on a throttle body idle air gap flow specification. Adjustments should only be

p

erformed when:

• TPS is replaced

• TPS or throttle body is mis-adjusted

• Troubleshooting erratic or inconsistent e

ngine idle, and/or engine performance

NOTE: Follow these guidelines whe

never working with the TPS:

• Use Digital Wrench® when checking the TPS volt

age. Do not use any other diagnostic tool.

• Disconnect throttle cable from the throttle lever. If the TPS

idle voltage changes, the throttle cable is too tight.

Readjust throttle cable.

• Verify the throttle cable is not pulling on the throttle

plate cam. Turn the throttle cable in line adjuster clockwise to

loosen the cable. If the cable continues to pull on the throttle plate cam, readjust the throttle cable threaded

barrel on the throttle body.

• All engine management sensors/switches

must be connected to obtain accurate TPS voltage readings.

• Use a fully charged 12VDC battery to power the

engine management system

The throttle position sensor (TPS) is set at the time of throttle body manufacture. TPS adjustments should only be

made if the TPS was loosened, repositioned, or replaced.

Any adjustments made to the idle air gap screw, TPS sensor, or throttle synchronization screw should only be

performed when directed to so by the Digital Wrench® Diagnostic Software.

Loading...

Loading...