PERIODIC MAINTENANCE

3-18

EAS30641

CHECKING THE WHEEL BEARINGS

The following procedure applies to all of the

wheel bearings.

1. Check:

• Wheel bearings

Refer to “CHECKING THE FRONT WHEEL”

on page 4-21 and “CHECKING THE REAR

WHEEL” on page 4-31.

EAS30802

CHECKING THE SWINGARM OPERATION

1. Check:

• Swingarm operation

Swingarm not working properly Check the

swingarm.

Refer to “SWINGARM” on page 4-95.

2. Check:

• Swingarm excessive play

Refer to “SWINGARM” on page 4-95.

EAS30643

LUBRICATING THE SWINGARM PIVOT

1. Lubricate:

• Oil seals

• Collars

Refer to “INSTALLING THE SWINGARM” on

page 4-97.

EAS31923

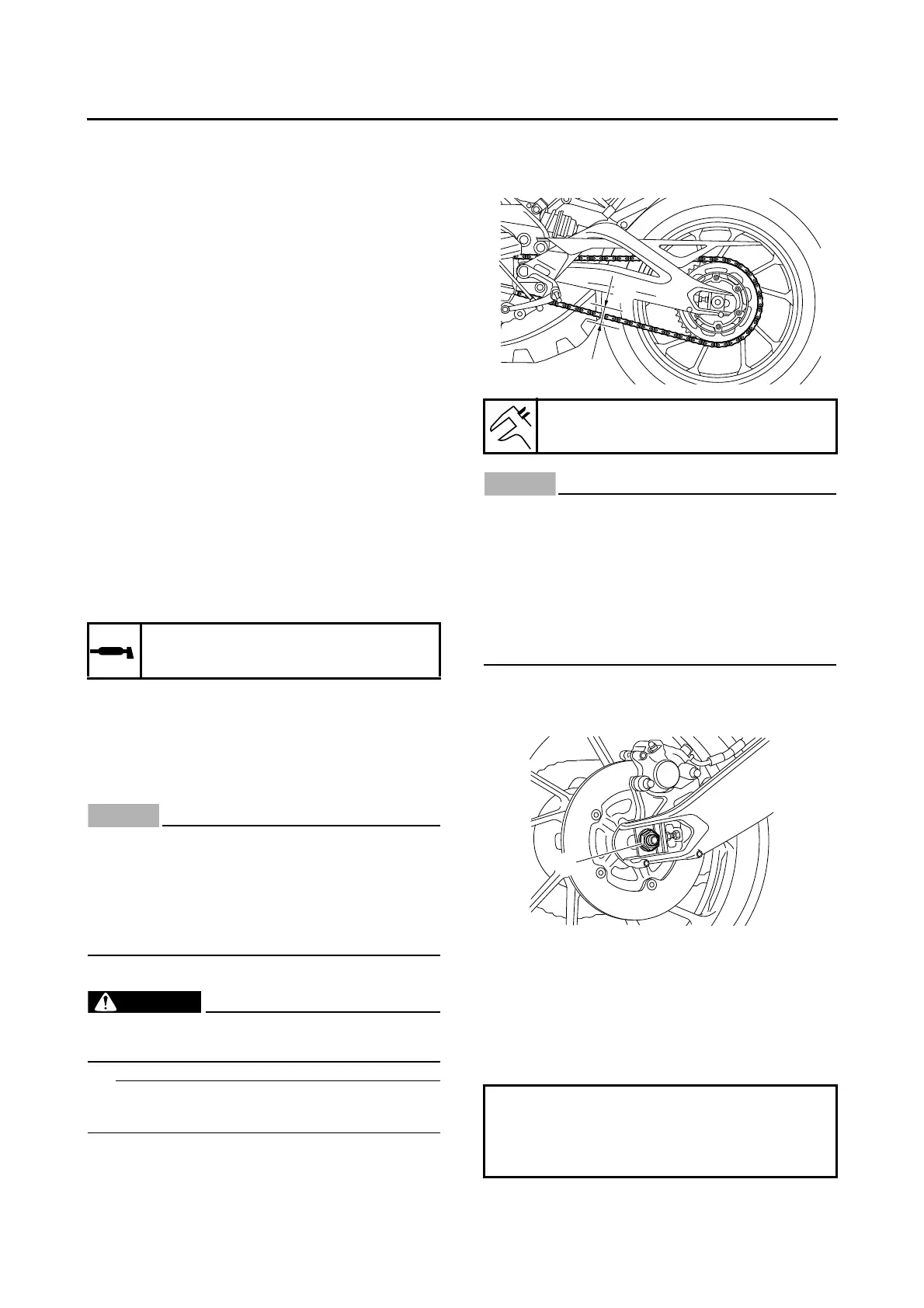

DRIVE CHAIN SLACK

Checking the drive chain slack

ECA13550

A drive chain that is too tight will overload

the engine and other vital parts, and one that

is too loose can skip and damage the swing-

arm or cause an accident. Therefore, keep

the drive chain slack within the specified lim-

its.

1. Stand the vehicle on a level surface.

EWA13120

Securely support the vehicle so that there is

no danger of it falling over.

Place the vehicle on the centerstand so that the

rear wheel is elevated.

2. Shift the transmission into the neutral posi-

tion.

3. Check:

• Drive chain slack “a”

Out of specification Adjust.

ECA20870

Improper drive chain slack will overload the

engine as well as other vital parts of the mo-

torcycle and can lead to chain slippage or

breakage. If the drive chain slack is more

than the specified limit, the chain can dam-

age the frame, swingarm, and other parts. To

prevent this from occurring, keep the drive

chain slack within the specified limits.

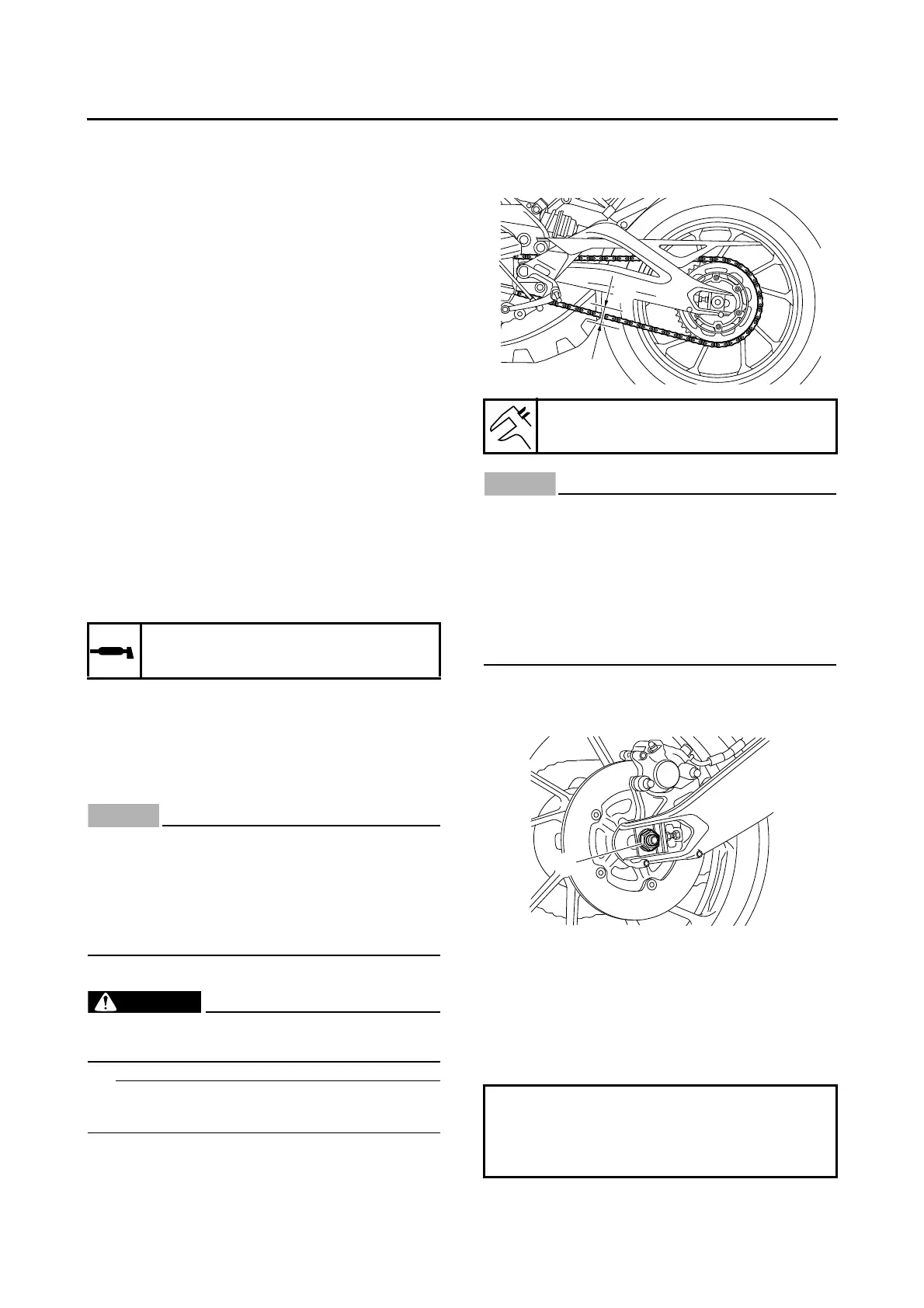

Adjusting the drive chain slack

1. Loosen:

• Wheel axle nut “1”

2. Adjust:

• Drive chain slack

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen both locknuts “1”.

b. Turn both adjusting bolts “2” in direction “a” or

“b” until the specified drive chain slack is ob-

tained.

Recommended lubricant

Lithium-soap-based grease

Drive chain slack

5.0–15.0 mm (0.20–0.59 in)

Direction “a”

Drive chain is tightened.

Direction “b”

Drive chain is loosened.

Loading...

Loading...