IMPORTANT INFORMATION

1-18

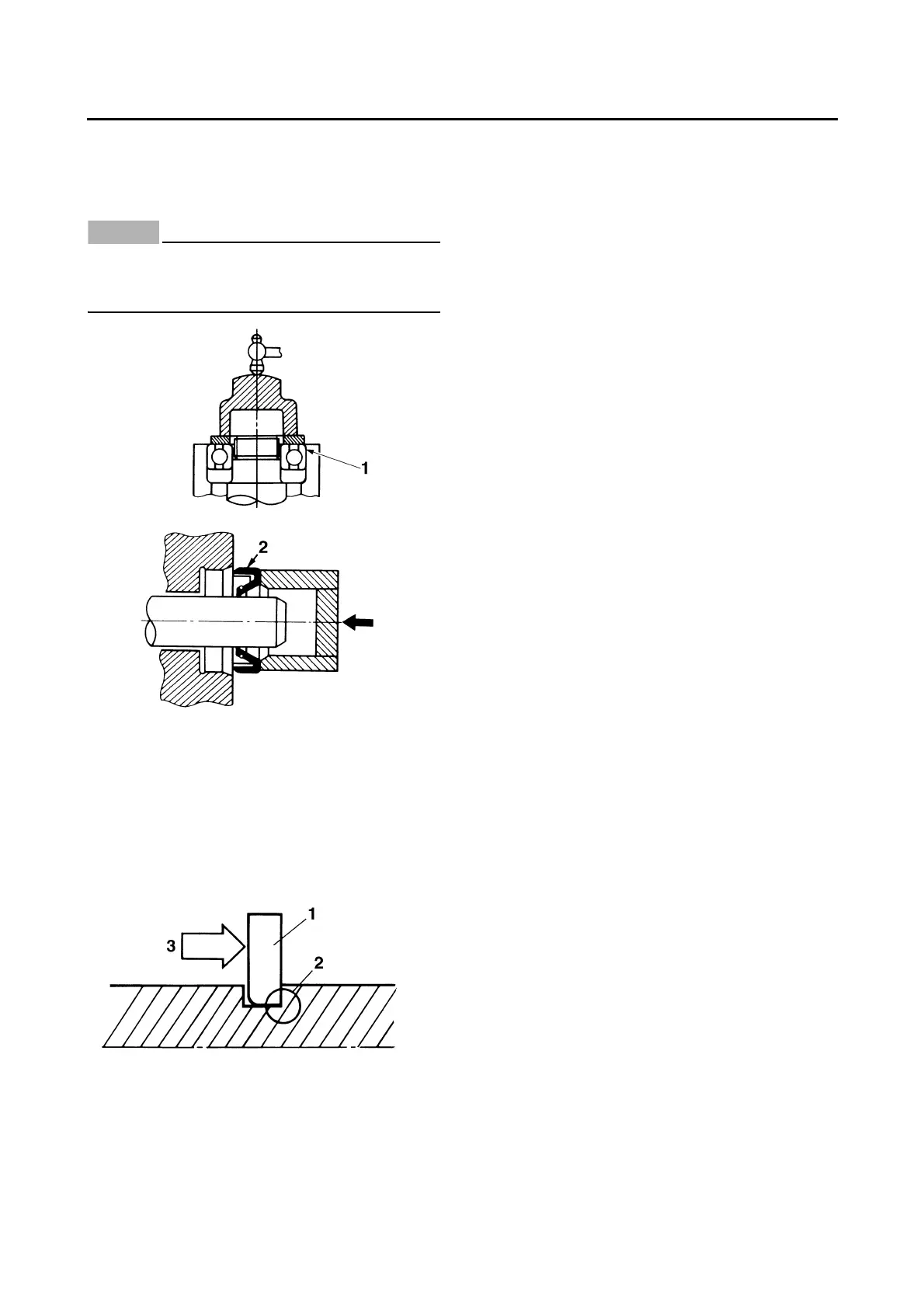

When installing oil seals, lubricate the oil seal

lips with a light coat of lithium-soap-based

grease. Oil bearings liberally when installing, if

appropriate.

ECA13300

Do not spin the bearing with compressed air

because this will damage the bearing surfac-

es.

EAS30011

CIRCLIPS

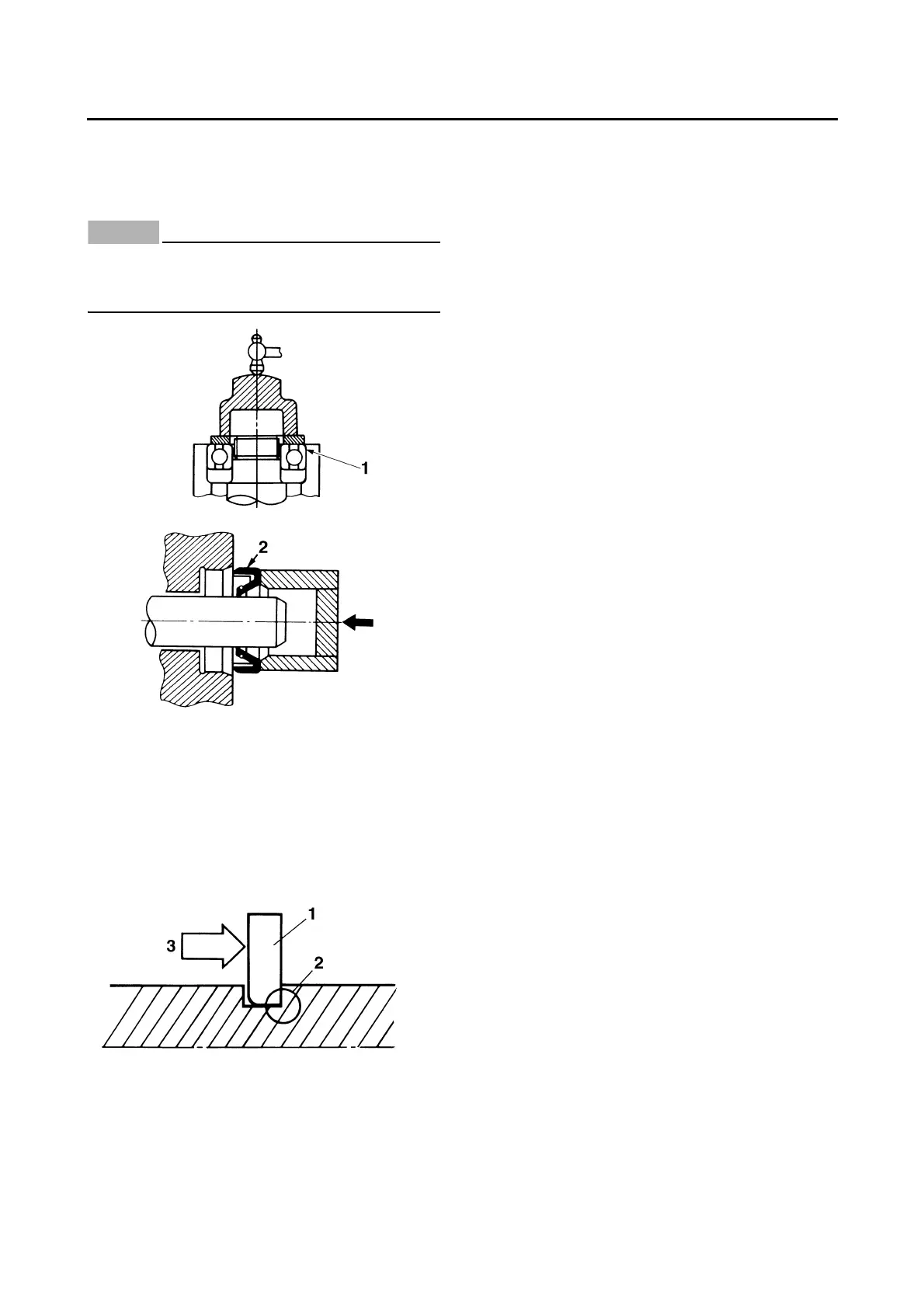

Before reassembly, check all circlips carefully

and replace damaged or distorted circlips. Al-

ways replace piston pin clips after one use.

When installing a circlip “1”, make sure the

sharp-edged corner “2” is positioned opposite

the thrust “3” that the circlip receives.

EAS30012

RUBBER PARTS

Check rubber parts for deterioration during in-

spection. Some of the rubber parts are sensitive

to gasoline, flammable oil, grease, etc. Do not al-

low any items other than the specified one to

contact the parts.

Loading...

Loading...