SWINGARM

4-97

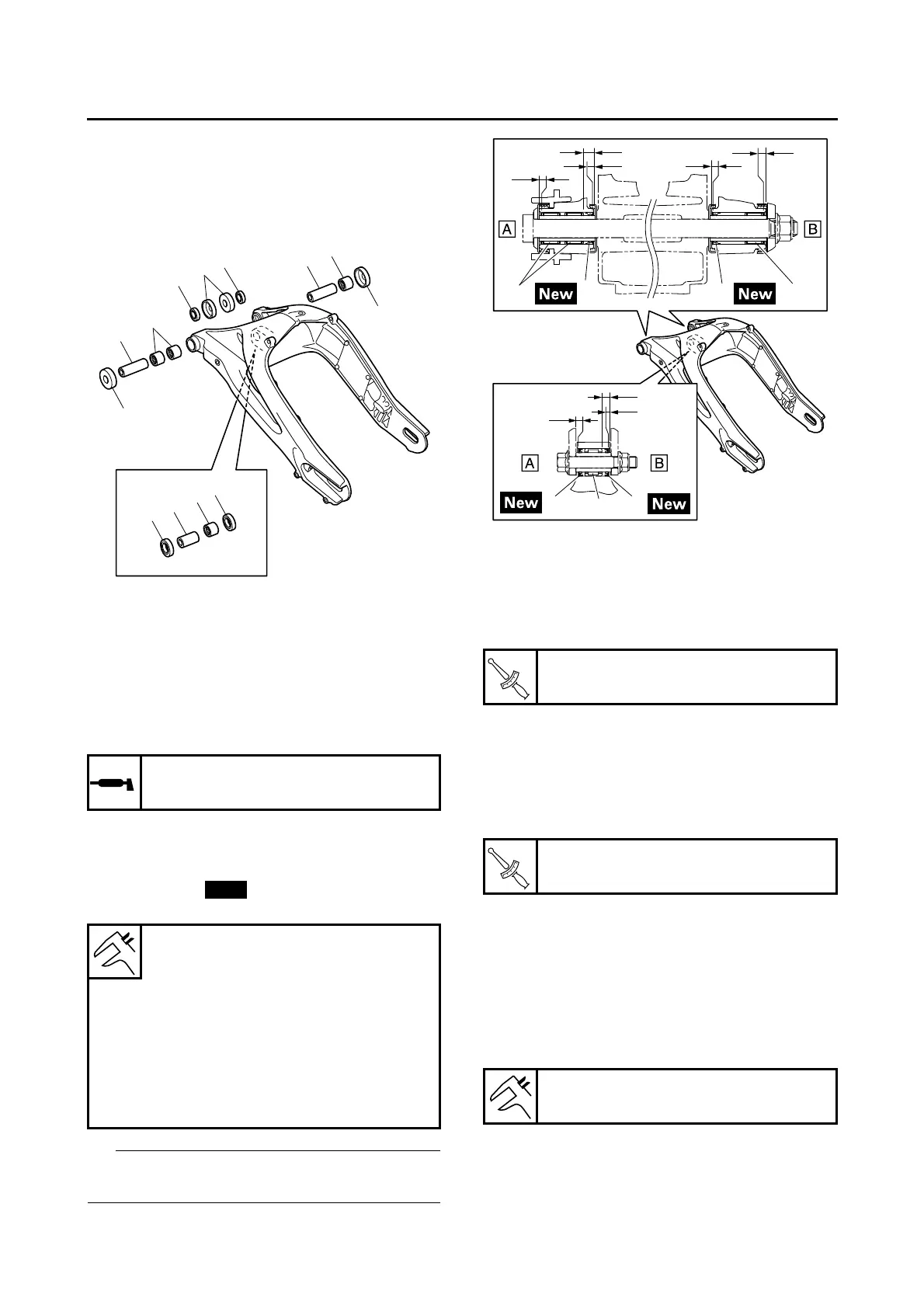

• Collars “3”

Damage/scratches Replace.

• Bearings “4”

Damage/pitting Replace.

EAS30228

INSTALLING THE SWINGARM

1. Lubricate:

• Dust covers

• Pivot shaft

• Oil seals

• Collars

2. Install:

• Bearings “1”

(to the swingarm)

• Oil seals “2”

(to the swingarm)

When installing the oil seals to the swingarm,

face the character stamp of the oil seals outside.

3. Install:

• Swingarm

• Pivot shaft

4. Install:

• Drive chain

Refer to “INSTALLING THE DRIVE CHAIN”

on page 4-101.

• Connecting arm lower bolt

• Connecting arm lower nut

• Rear wheel

Refer to “REAR SHOCK ABSORBER AS-

SEMBLY” on page 4-91 and “REAR WHEEL”

on page 4-27.

5. Adjust:

• Drive chain slack

Refer to “DRIVE CHAIN SLACK” on page

3-18.

Recommended lubricant

Lithium-soap-based grease

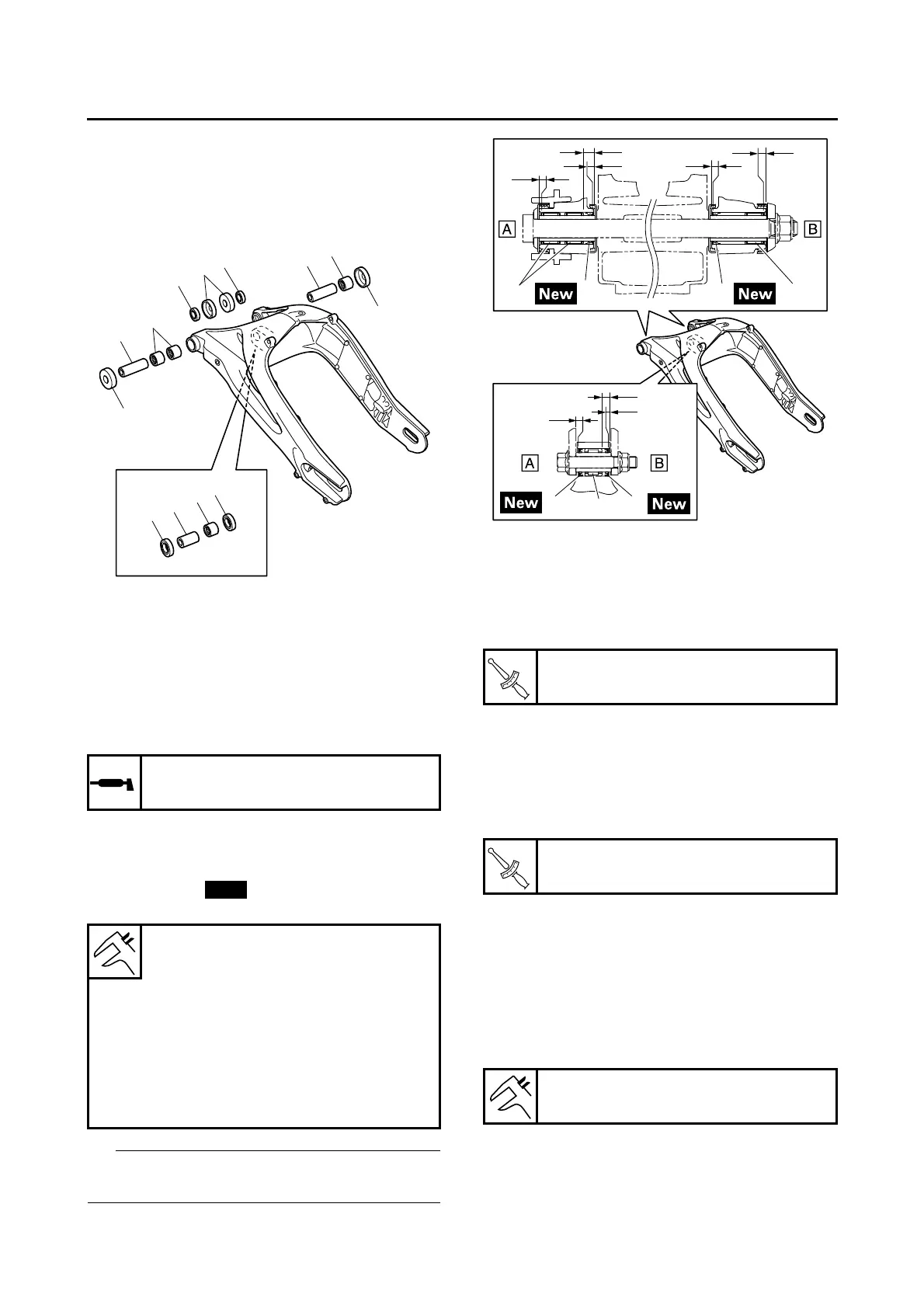

Installed depth “a”

2.0 mm (0.08 in)

Installed depth “b”

9.0 mm (0.35 in)

Installed depth “c”

0.5–1.5 mm (0.02–0.06 in)

Installed depth “d”

7.0 mm (0.28 in)

Installed depth “e”

1.5–2.5 mm (0.06–0.10 in)

A. Left side

B. Right side

Pivot shaft nut

110 N·m (11 kgf·m, 80 lb·ft)

Connecting arm lower nut

55 N·m (5.5 kgf·m, 40 lb·ft)

Drive chain slack

5.0–15.0 mm (0.20–0.59 in)

Loading...

Loading...