CRANKSHAFT AND BALANCER SHAFT

5-72

EAS31171

REMOVING THE CRANKSHAFT AND

BALANCER SHAFT

1. Remove:

• Balancer shaft “1”

• Balancer shaft journal bearing

• Crankshaft assembly “2”

• Crankshaft journal bearings

Identify the position of each balancer shaft jour-

nal bearings and crankshaft journal bearings so

that it can be reinstalled in its original place.

EAS31174

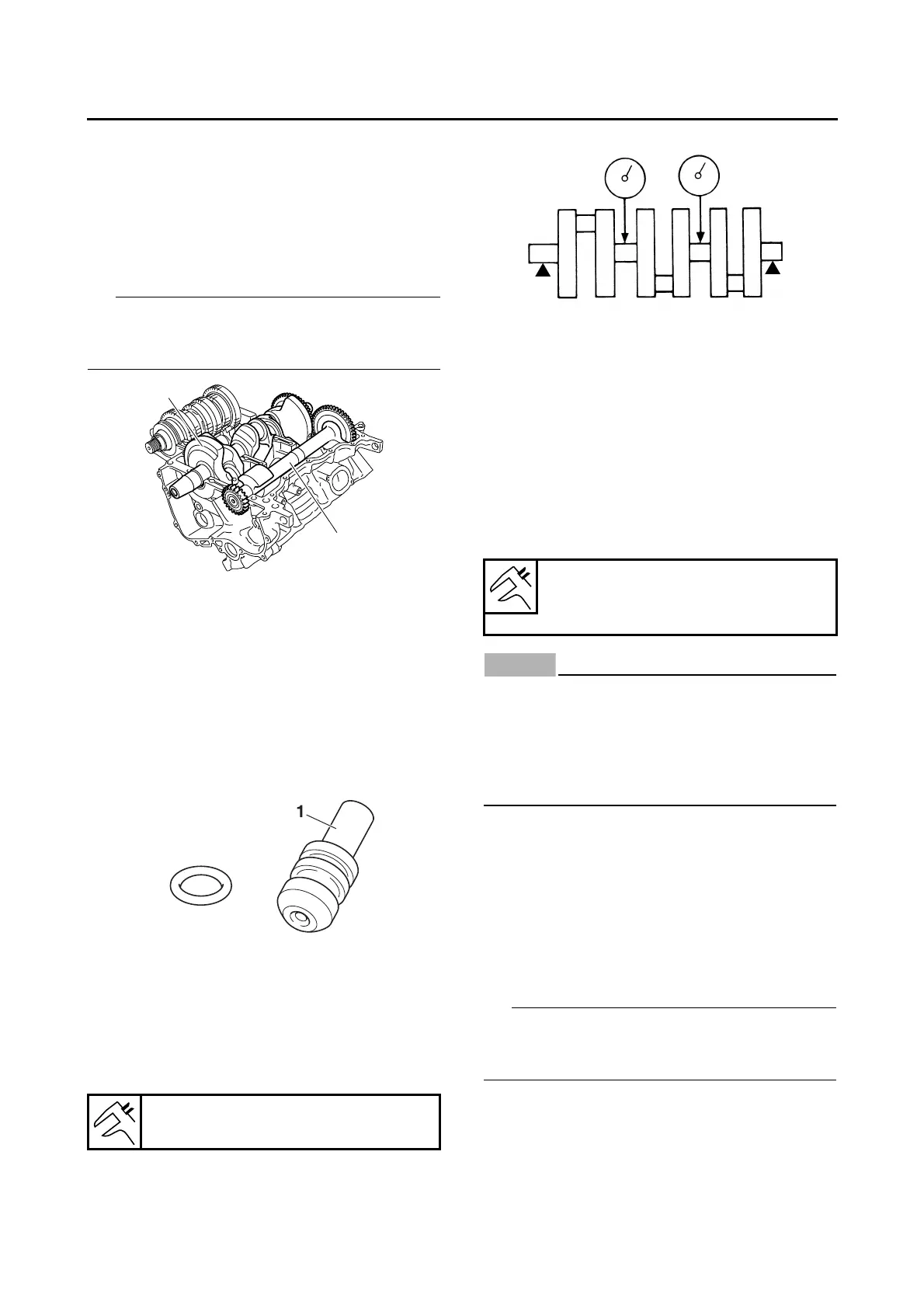

CHECKING THE OIL NOZZLES

The following procedure applies to all of the oil

nozzles.

1. Check:

• Oil nozzle “1”

Damage/wear Replace the oil nozzle.

• Oil passage

Obstruction Blow out with compressed air.

EAS31075

CHECKING THE CRANKSHAFT

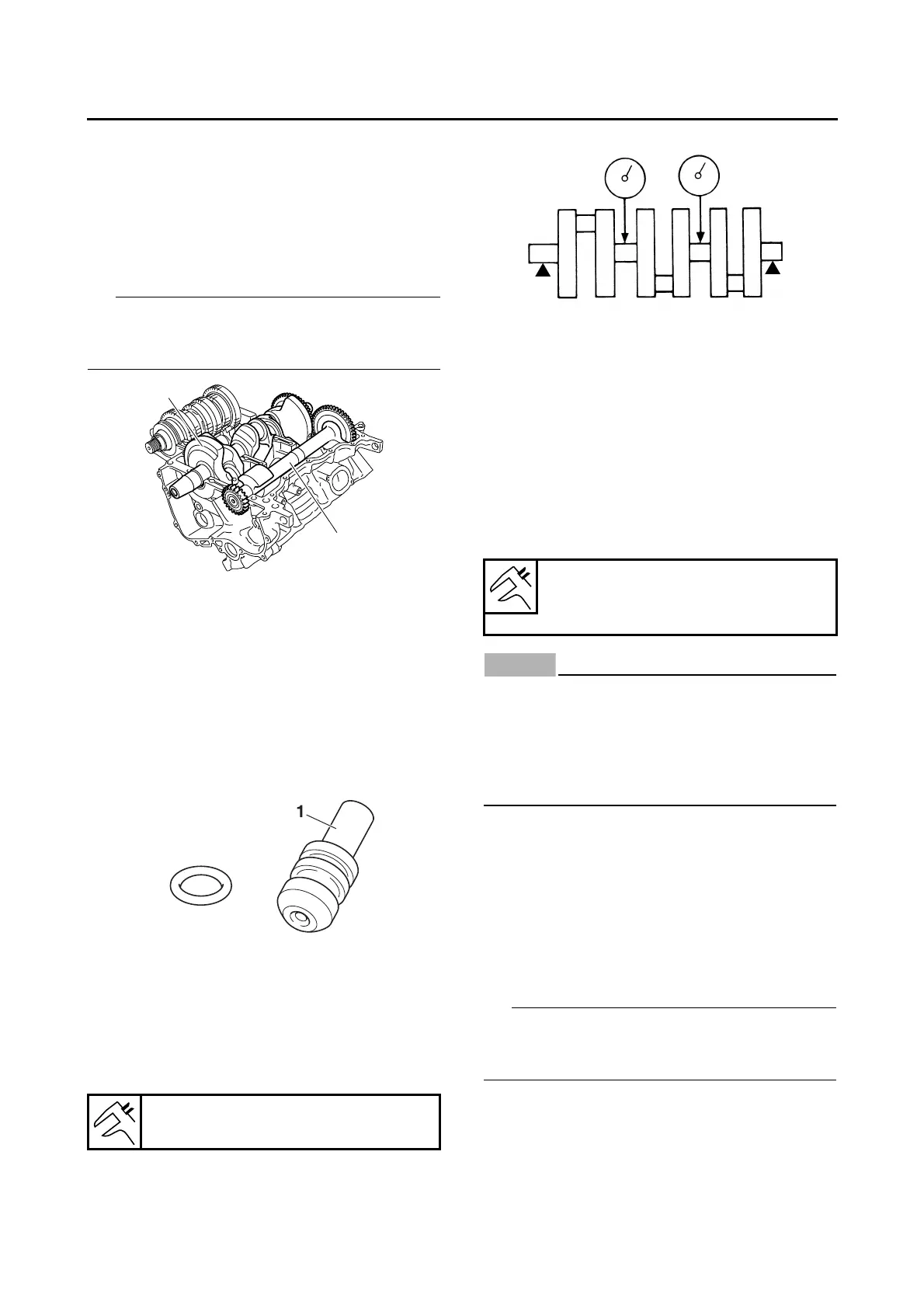

1. Measure:

• Crankshaft runout

Out of specification Replace the crank-

shaft.

2. Check:

• Crankshaft journal surfaces

• Crankshaft pin surfaces

• Bearing surfaces

Scratches/wear Replace the crankshaft.

3. Measure:

• Crankshaft-journal-to-crankshaft-journal-

bearing clearance

Out of specification Replace the crank-

shaft journal bearings.

ECA13920

Do not interchange the crankshaft journal

bearings. To obtain the correct crankshaft-

journal-to-crankshaft-journal-bearing clear-

ance and prevent engine damage, the crank-

shaft journal bearings must be installed in

their original positions.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Clean the crankshaft journal bearings, crank-

shaft journals, and bearing portions of the

crankcase.

b. Place the upper crankcase upside down on a

bench.

c. Install the crankshaft journal upper bearings

“1” and the crankshaft into the upper crank-

case.

Align the projections “a” on the crankshaft jour-

nal upper bearings with the notches “b” in the up-

per crankcase.

Runout limit

0.030 mm (0.0012 in)

Journal oil clearance

0.014–0.038 mm (0.0006–0.0015

in)

Loading...

Loading...