G.15Part. N. 8000 B0148 (02-2008)

ENGINE OVERHAULING

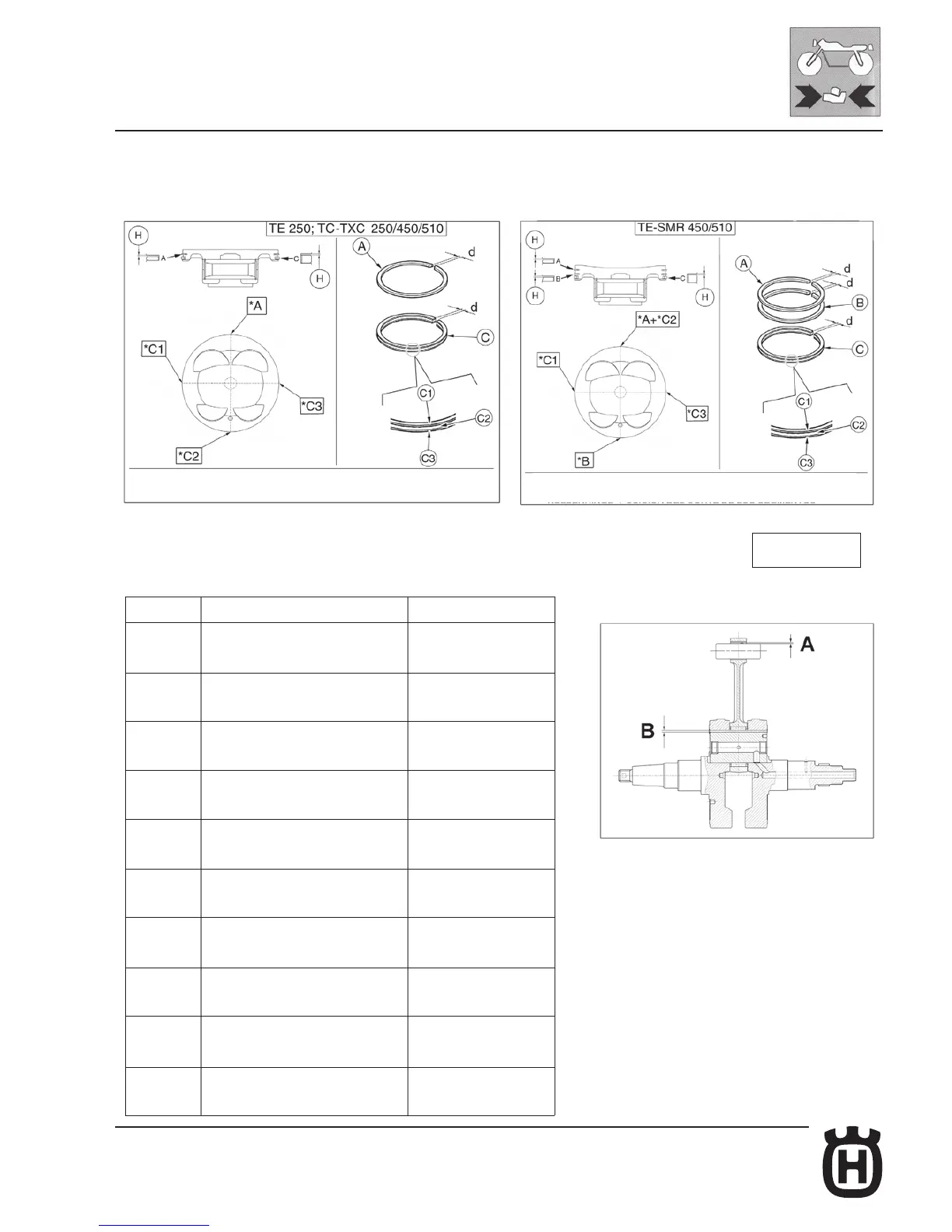

Piston ring/Piston rings groove clearance

Use a feeler gauge to check the axial play (H) of the rings in the groove. The manufacturer mark, if it is present on the piston ring, must

be turned upwards.

*: "d" cut posistion

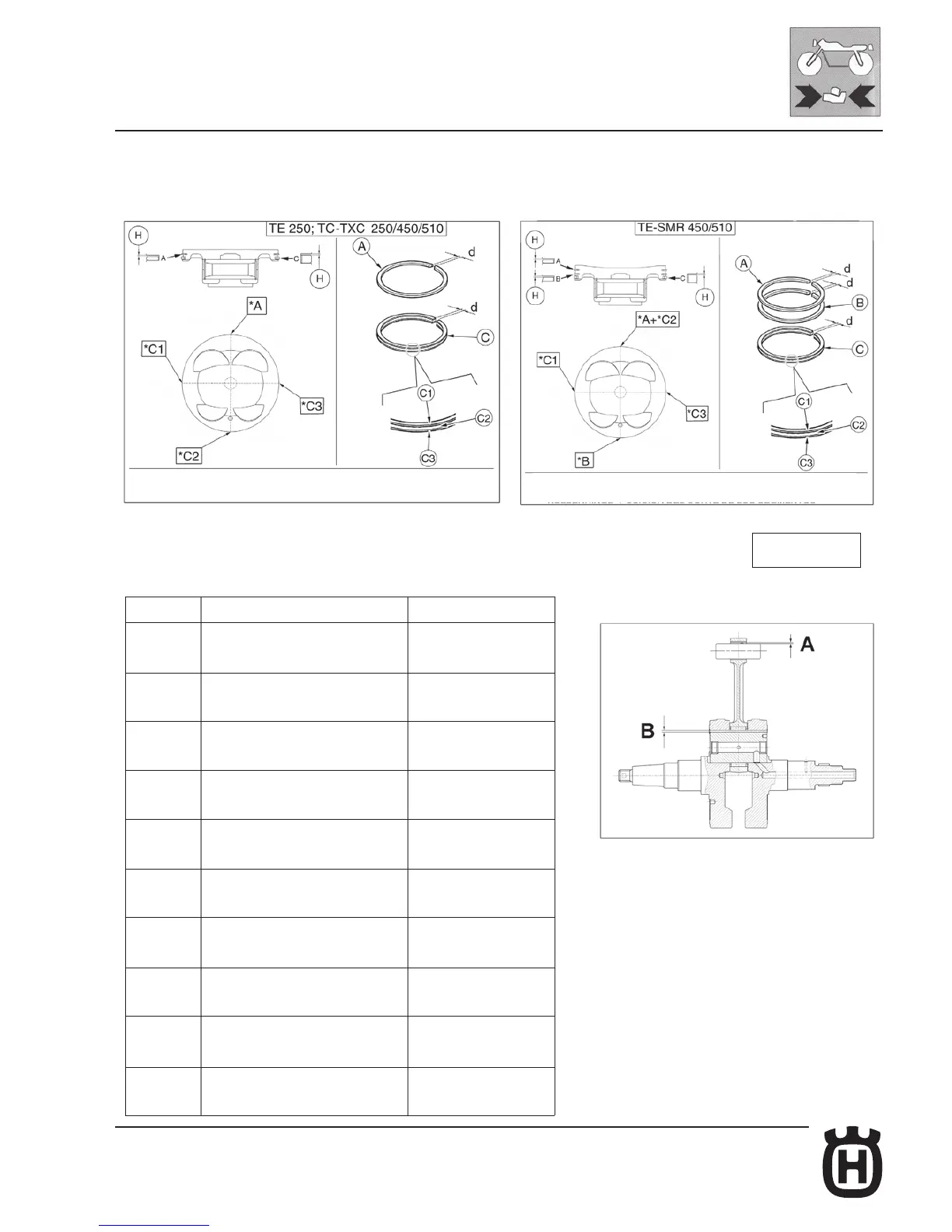

Gudgeon pin/conrod small end clearance (A): 0.00047÷0.00106 in. WEAR LIMIT: 0.0022 in.

Conrod big end radial clearance (B): 0.00102÷0.00141 in. WEAR LIMIT: 0.00315 in.

PISTON RING CUT SETTING

PISTON RING CUT SETTING

PISTON RING NOMINAL CLEARANCE (H) WEAR LIMIT

"A" TE, TC, TXC 250: 0,011÷0,033 mm 0,07 mm

(0.00043÷0.00130 in.) (0.0027 in.)

"A" TC, TXC 450-510: 0,070÷0,110 mm 0,22 mm

(0.00027÷0.0043 in.) (0.0087 in.)

"A" TE-SMR 450: 0,065÷0,100 mm 0,24 mm

(0.00256÷0.00394 in.) (0.009 in.)

"A" TE-SMR 510: 0,030÷0,065 mm 0,13 mm

(0.00012÷0.0025 in.) (0.0051 in.)

"B" TE-SMR 450: 0,035÷0,070 mm 0,15 mm

(0.00138÷0.00027 in.) (0.0059 in.)

"B" TE-SMR 510: 0,020÷0,055 mm 0,11 mm

(0.0008÷0.0022 in.) (0.0043 in.)

"C" TE, TC, TXC 250: 0,040÷0,110 mm 0,22 mm

(0.0016÷0.0043 in.) (0.0087 in.)

"C" TC, TXC 450-510: 0,040÷0,120 mm 0,24 mm

(0.00016÷0.0047 in.) (0.0094 in.)

"C" TE- SMR 450: 0,020÷0,110 mm 0,20 mm

(0.0008÷0.0043 in.) (0.0079 in.)

"C" TE- SMR 510: 0,010÷0,180 mm 0,35 mm

(0.0004÷0.0071 in.) (0.0138 in.)

Loading...

Loading...