Y.12 Part. N. 8000 B0148 (02-2008)

FRAME AND WHEELS

Wheels overhauling

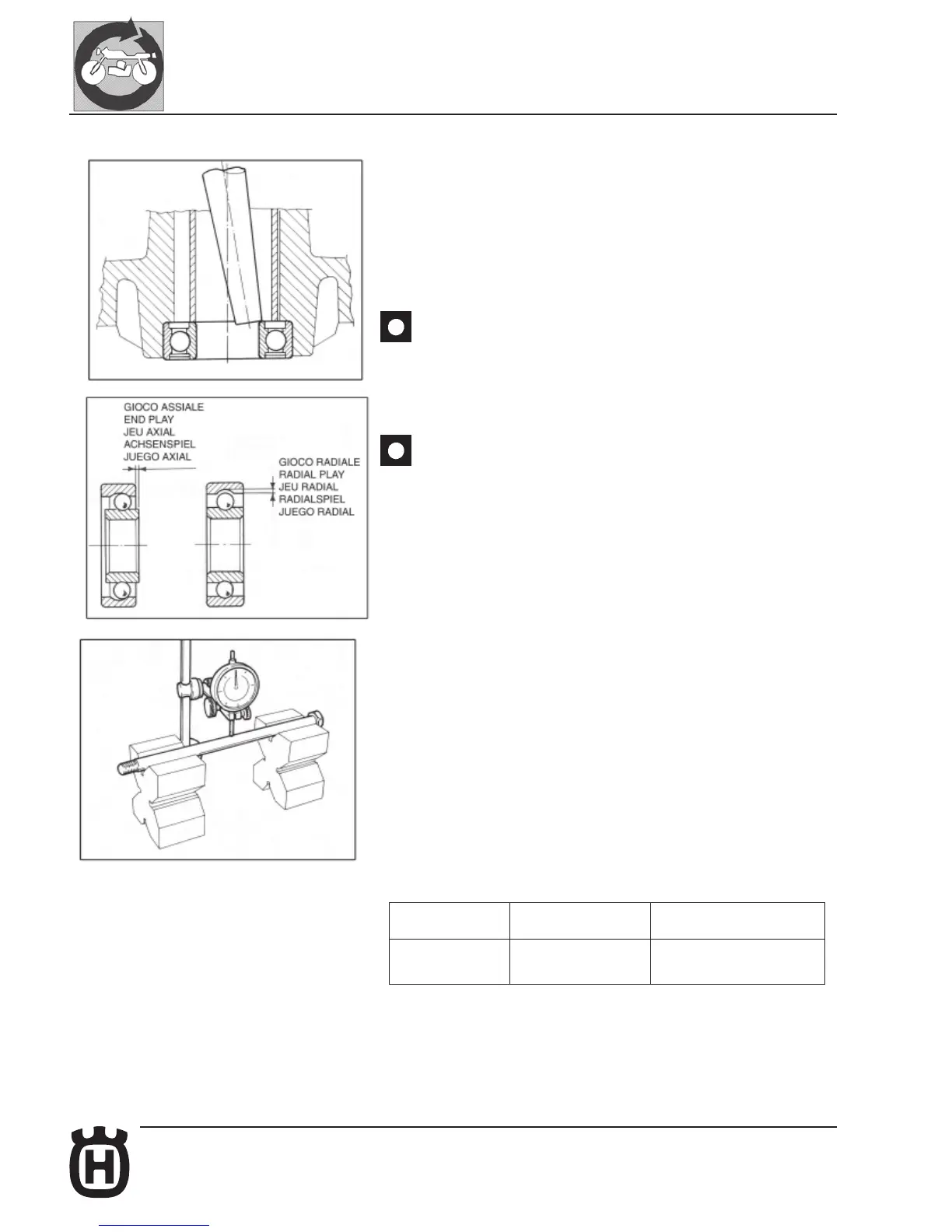

Check the wear state of the hub bearings. In case of excessive clearance (radial

and axial), operate as follows:

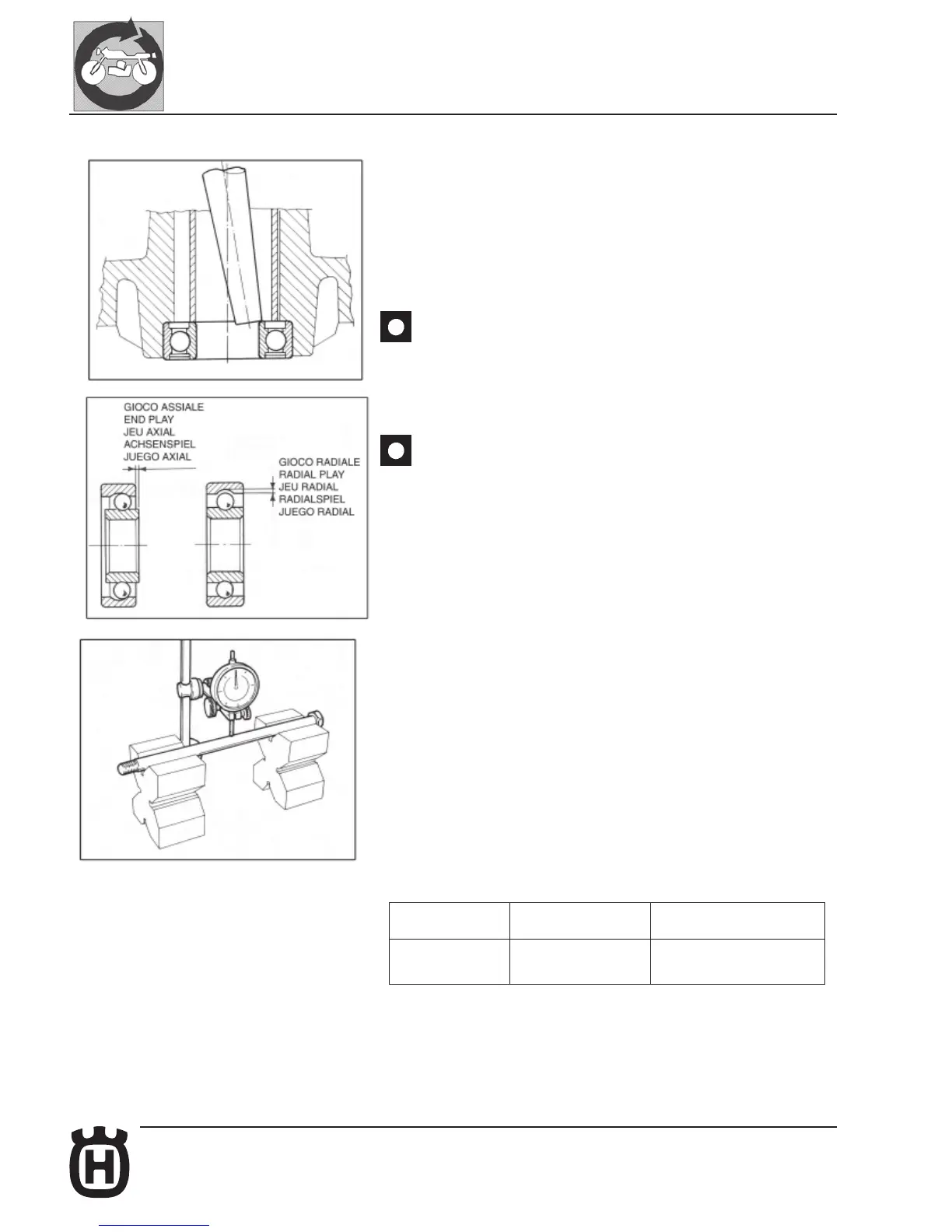

- lay the hub on a flat holder with hole, allowing for the passage of the removed

bearing;

- use a hammer and a pin to exercise pressure only on the bearing inner ring

(see figure) up to its removal;

- continuosly change the pressure position so to get an extraction as regular as

possible;

- extract the spacer and perform the same operations for the other bearing.

Removed bearings must not be reassembled.

When reassembling new bearings checl the seat. It must be clean and without

grooves or scatches. Grease the seat before fitting the bearing, then put it in the seat

using a proper tubolar pad, exercising pressure only on the bearing outer ring uo to

complete inserting. Place the spacer and the proceed with the placing of the other

bearing. Check their alignement by placing the wheel pin.

After every intervention on wheels their balancing is advisable.

Wheel axle bending

If the bending figure is over the allowable max limit, straighten or replace the axle.

If the axle can not the straightened within the prescribed limits, replace it.

Axle out of track 100 mm

Wheel axle Standard Max wear limit

Wheel axle less than 0.004 in. 0,2 mm (0.0078 in.)

Loading...

Loading...