1

11. SERVICE MODE Field Service Ver. 2.0 Jun. 2010

106

bizhub 164

ADJUSTMENT / SETTING

11.4.14 CIS SUB REGIST

A. Use

•To adjust variations in machining and installation accuracy of different scanner parts by

varying the starting position of image scanning in the sub scanning direction.

•Used when the PH unit has been replaced.

(After PRN MAIN REGIST, PRN SUB REGIST, and CIS MAIN ZOOM have been

adjusted)

•Used when the CIS module has been replaced. (After the CIS module has been adjusted

for correct position)

B. Procedure

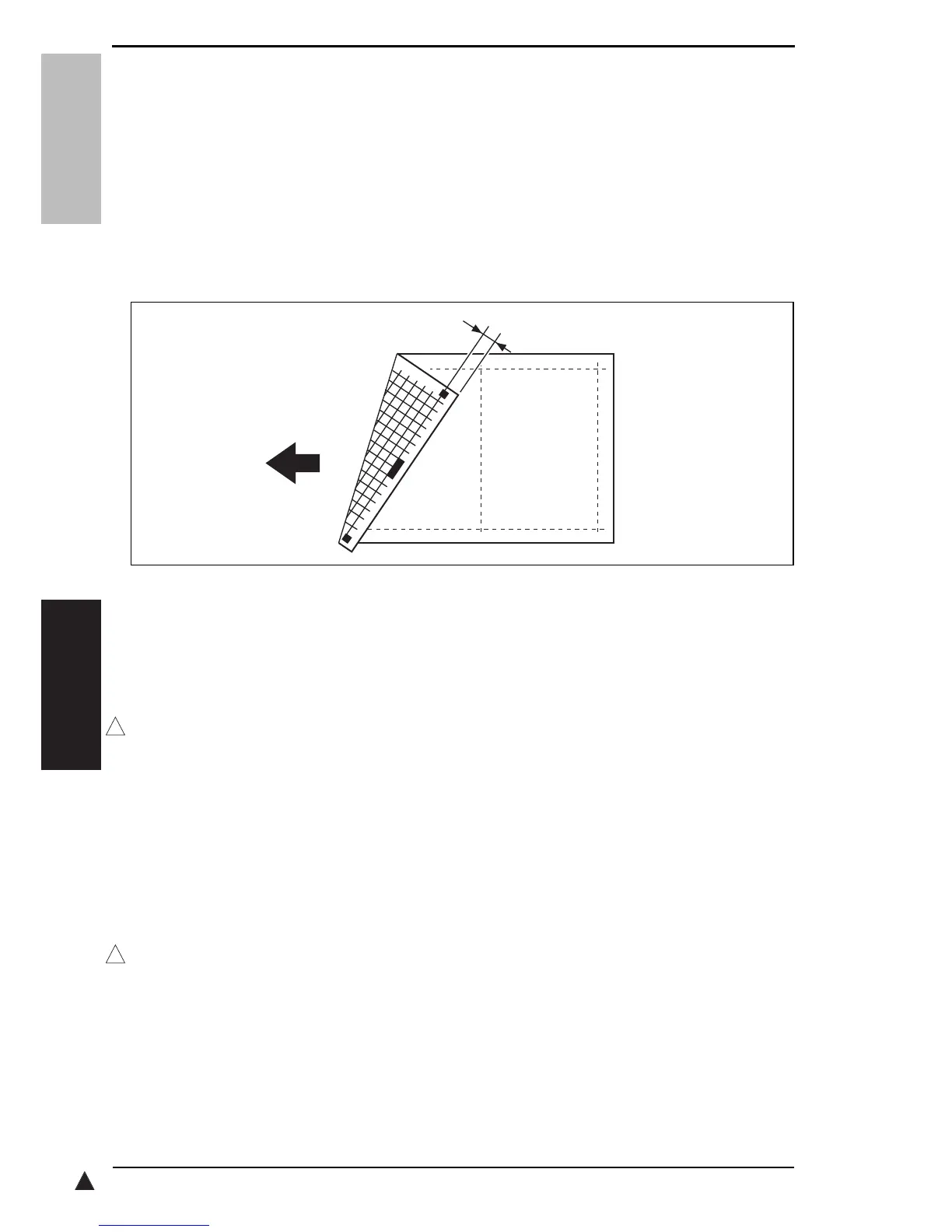

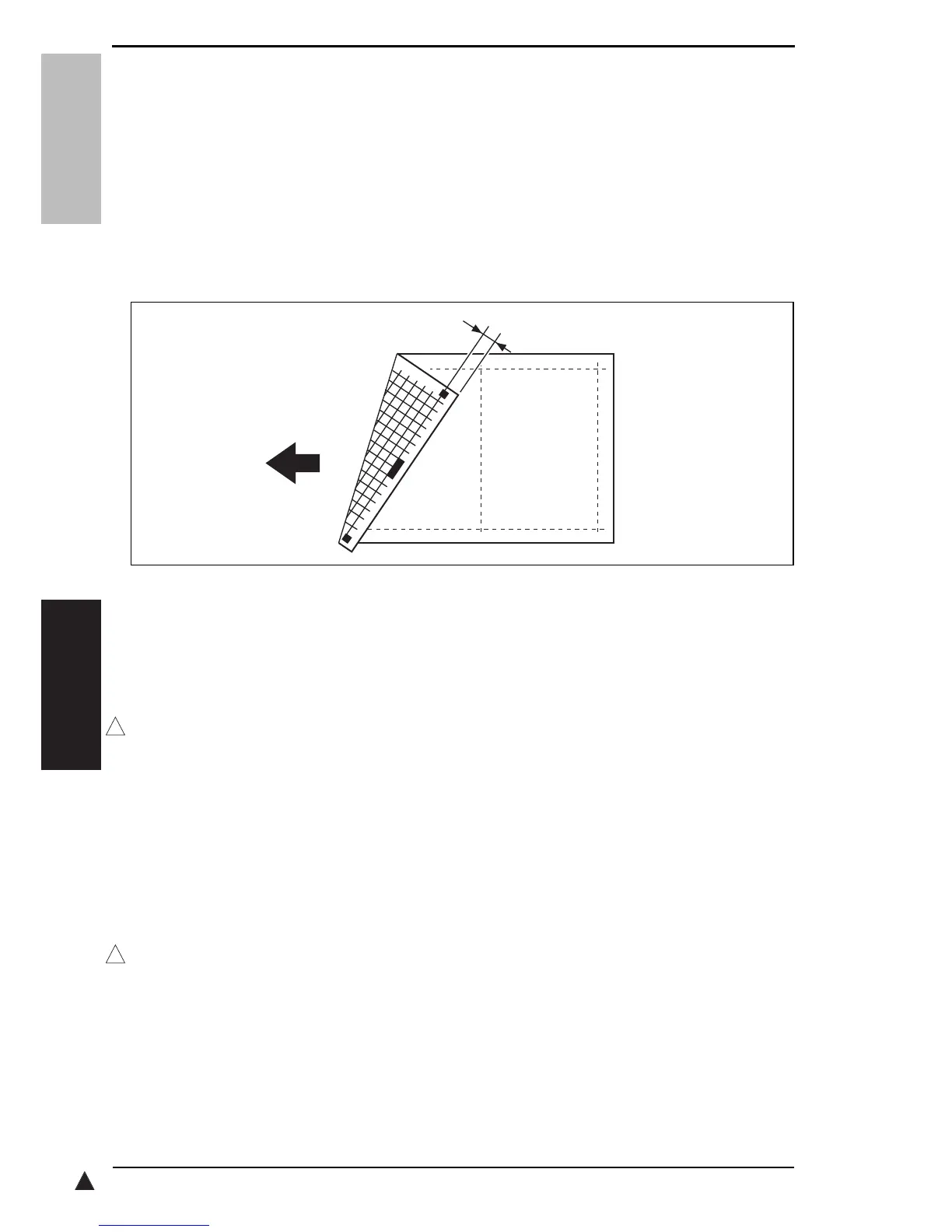

•Adjust so that deviation between width A on the test pattern produced and that on the

copy produced falls within the specified range.

•Specifications: 0 ± 1.5 mm

60 (-4.0 mm) to 140 (+4.0 mm) (1 step: 0.1 mm)

1. Load the tray 1 with A3/11 x 17 paper.

2. Enter function of the SERVICE MODE.

3. Select [FUNCTION] → [PRN TEST PATTERN] → [TRAY1] → [TEST PATTERN1].

Then, press the Menu/Select key.

This will produce a test pattern.

4. Place the test pattern produced in step 3 on the original glass and make a copy of it.

5. Place the test pattern (original) on top of the copy and check for deviation in width A.

If the deviation in width A falls outside the specified range, perform the following steps

to make an adjustment.

6. Select [CIS SUB REGIST] of [ADJUST].

7. Using [ ▲ / ▼ ] key, select the appropriate setting value.

If the deviation is longer than the specifications, increase the setting value.

If the deviation is shorter than the specifications, decrease the setting value.

8. Press the Menu/Select key to validate the setting value selected in step 7.

9. If a single adjustment procedure does not successfully bring the deviation into the

specified range, repeat steps 5 through 7.

A0XXF3C505DA

A

1

1

Loading...

Loading...