16. IMAGE QUALITY PROBLEM Field Service Ver. 2.0 Jun. 2010

138

bizhub 164

TROUBLESHOOTING

16. IMAGE QUALITY PROBLEM

16.1 How to identify problematic part

•In this chapter, troubleshooting is divided into “initial checks” and “troubleshooting proce-

dures classified by image failures.”

•If any image failure has occurred, first make the initial checks, then proceed to the corre-

sponding image failure troubleshooting procedure.

16.1.1 Initial check items

•Determine if the failure is attributable to a basic cause or causes.

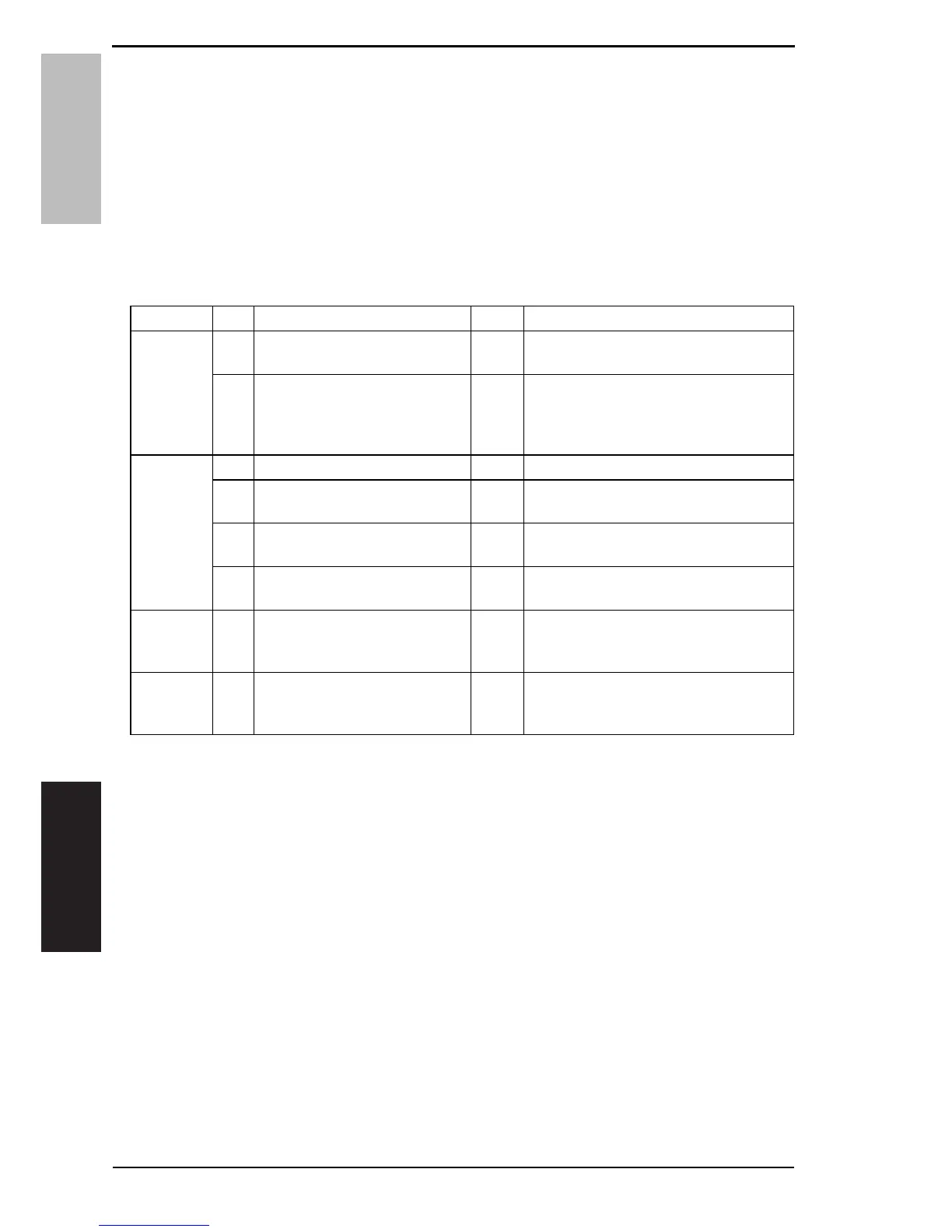

Section Step Check Result Action

Paper 1 Paper meets product specifica-

tions.

NO • Instruct user to use paper that meets

specifications and is recommended.

2Paper is damp. YES•Change paper for one that is dry.

Then, instruct user to use paper that

meets specifications and in how to

store paper.

Original 3 Original is placed correctly. NO • Reposition original.

4Original is written in light pencil.YES•Instruct user to use original with

appropriate image density.

5Original is transparent (OHP

film, etc.).

YES • Instruct user to use originals that meet

specifications.

6Original glass is dirty or

scratchy.

YES • Clean original glass.

•Change original glass.

PM parts 7 The PM parts relating to image

formation have reached the end

of cleaning/replacement cycles.

YES • Clean PM parts.

•Change PM parts.

Adjust-

ment items

8Adjustment item in which re-

adjustment is made to improve

the image faulty.

YES • Re-adjustment

Loading...

Loading...