Field Service Ver. 2.0 Jun. 2010 16. IMAGE QUALITY PROBLEM

153

bizhub 164

TROUBLESHOOTING

16.2.14 Printer section: Low image density

A. Typical faulty images

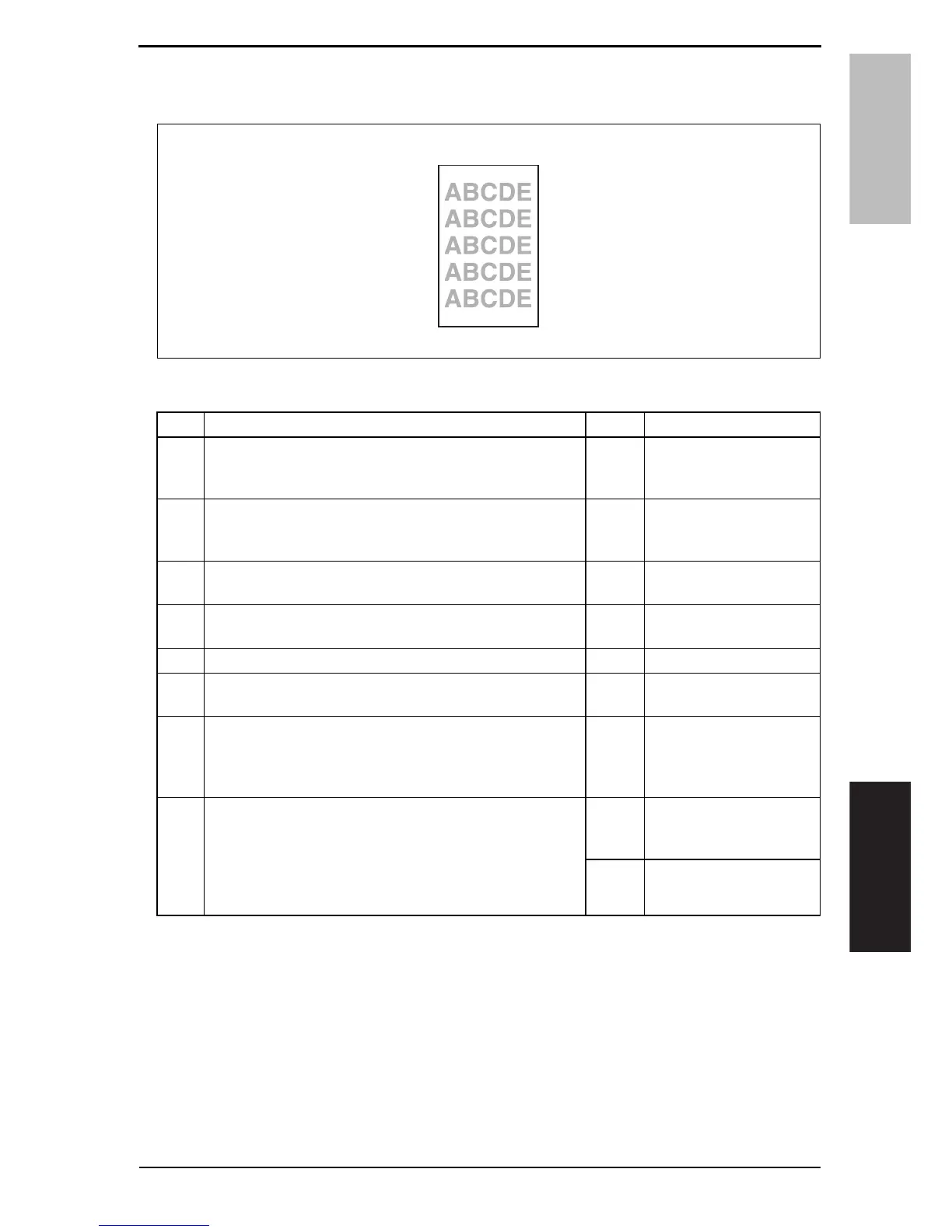

B. Troubleshooting procedure

A09AF3C524DA

Step Check Result Action

1The image changes when “TONER SUPPLY” in SERVICE

MODE is executed.

YES • Replenish the supply of

toner using “TONER

SUPPLY”.

2The image changes when “ID ADJUST” and “VG

ADJUST” are executed.

YES • Readjust.

For details, see

ADJUSTING/SETTING.

3Image transfer current contact is dirty, folded, or bent. YES•Clean, correct, or

change.

4Developing bias contact is dirty, folded, or bent. YES•Clean, correct, or

change.

5High voltage unit (HV1) connectors is loose. YES • Reconnect.

6TCR sensor (TCRS) is dirty with foreign matter

(such as paper dust) other than developer.

YES • Clean.

7Is a power voltage supplied across CN-2, 3 on PRCB?

<Check procedure>

•Check voltage across a master board pin and GND

when the power switch is turned ON.

NO • Change TCR sensor

(TCRS) and then

change developer.

8The following voltage is supplied from the printer control

board (PRCB).

<Check procedure>

•Check that there is 24 V developing across the printer

control board pin and GND when the power switch is

turned ON (during a copy cycle or a standby state).

YES • Change IU.

•Change high voltage

unit (HV1).

NO • Change printer control

board (PRCB).

Loading...

Loading...