3. PERIODICAL MIANTENANCE ITEMS Field Service Ver. 2.0 Jun. 2010

8

bizhub 164

MAINTENANCE

3.2 Periodical replacement parts list

•To ensure that the machine produces good copies and to extend its service life, it is rec-

ommended that the maintenance jobs described in this schedule be carried out as

instructed.

•Replace with reference to the numeric values displayed on the total counter, the life

counter or the messages displayed on the control panel.

•Maintenance conditions are based on the case of A4 or 8

1

/

2

x 11, standard mode* and

low power mode OFF.

3.2.1 Main body

*1: Actual durable cycle (PM counter value)

3.3 Periodical cleaning parts list

•Clean with reference to the numeric values displayed on the total counter, the life counter

or the messages displayed on the control panel.

3.3.1 Main body

*1: Total counter value

B/W

* Standard mode bizhub 164 2 pages per job

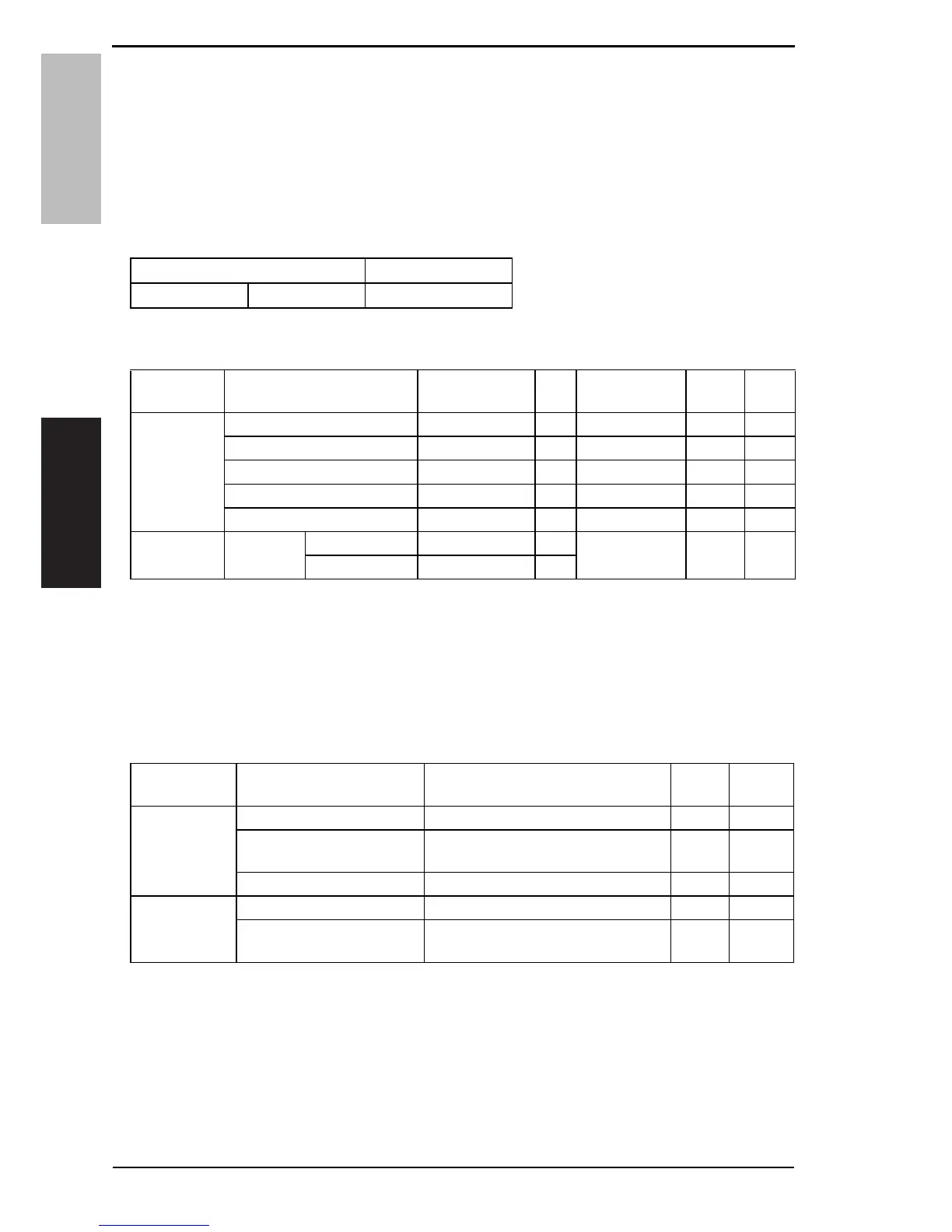

Classification Parts name Parts No. Qt. Replacing cycle

Descrip

tions

Ref.

page

Processing

section

Developer ⎯ 1 55,000 P. 1 0

Drum ⎯ 1 55,000 P. 1 4

Cleaning blade A0XX 3618 ## 1 55,000 P. 1 6

Drum charge corona assy A1XU R701 ## 1 55,000 P. 1 6

Toner b o t t l e ( TN 1 1 6 ) ⎯ 111,000 P. 1 9

Fusing

section

Fusing unit 220V - 240V A0XX PP6X ## 1 100,000 *1 P. 2 7

120V - 127V A0XX PP70 ## 1

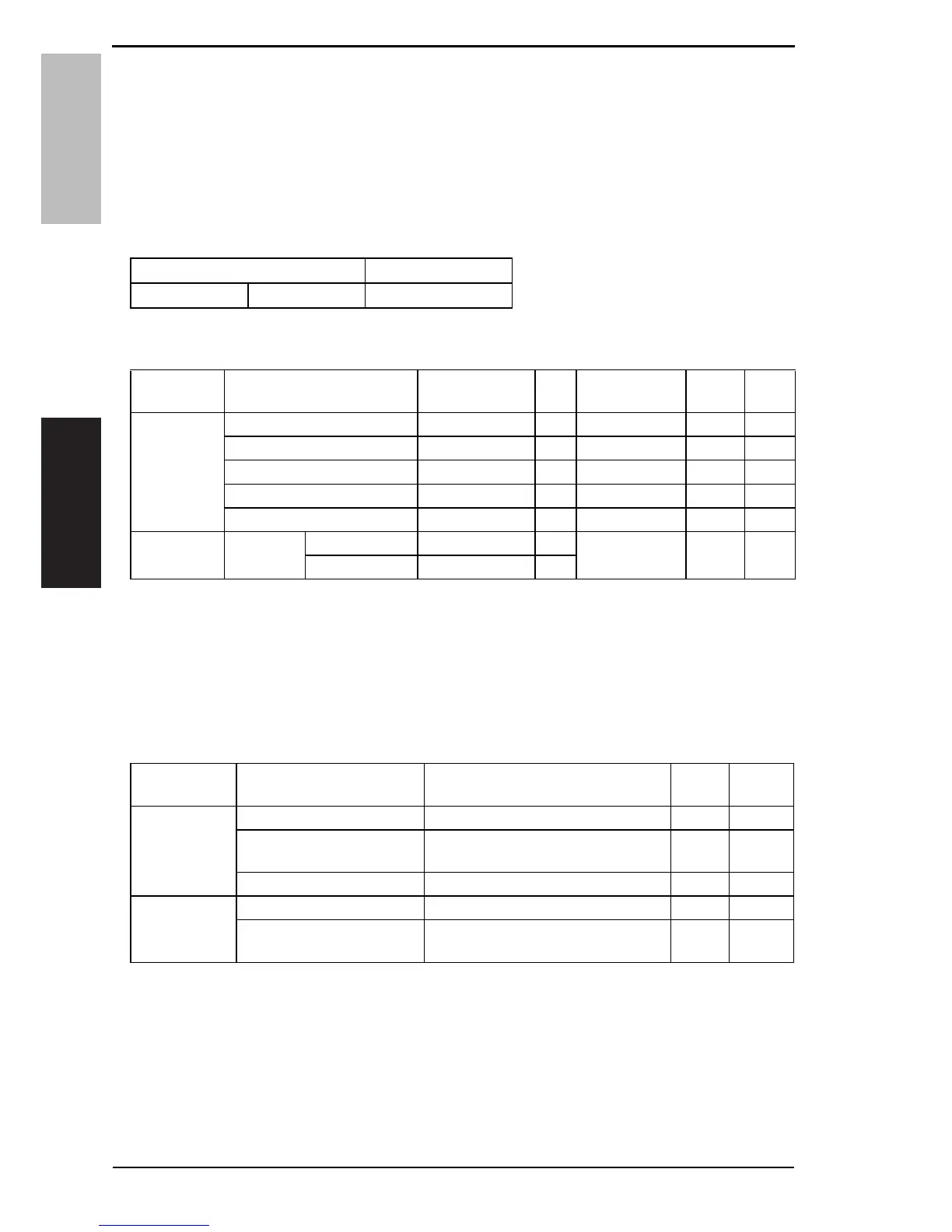

Classification Parts name Cleaning cycle

Descrip

tions

Ref.Page

Processing

section

Ds collars 55,000 *1 P. 2 1

Developer scattering

prevention plate

55,000 *1 P. 2 3

Drum separator fingers 55,000 *1 P. 2 2

Conveyance

section

Timing roller 55,000 *1 P. 2 5

Pre-image transfer guide

plate

55,000 *1 P. 2 5

Loading...

Loading...