Toyota Orderpicker Model 7BPUE 15 Service Manual

Section 7. Component Procedures

Electrical Components

Motors (General)

Motor Cleaning

within the motor.

Figure 7

-

43. Motor Cleaning with Com

p

ressed Air

Periodic cleaning is essential to prevent

overheating and shorts

-

to

-

frame. To clean a

motor properly:

1. Wear safety glasses or goggles to protect

your eyes from dust and debris.

2. Using an OSHA approved air nozzle, use

clean, dry, low pressure (30 psi or 207

kPa

or 2.1 kg/cm2) compressed air to blow

carbon dust and other foreign matter

from:

Motor housing

Brush holders

Commutator

Field and armature windings (if

accessible)

Motors (General)

ACAUTION

Never use a chemical solvent to clean a

motor, as it can carry carbon dust to

inaccessible areas and cause shorts

ACAUTION

Cleaning a motor with solvents requires

complete disassembly and drying, and

should only be performed by an

authorized motor repair shop.

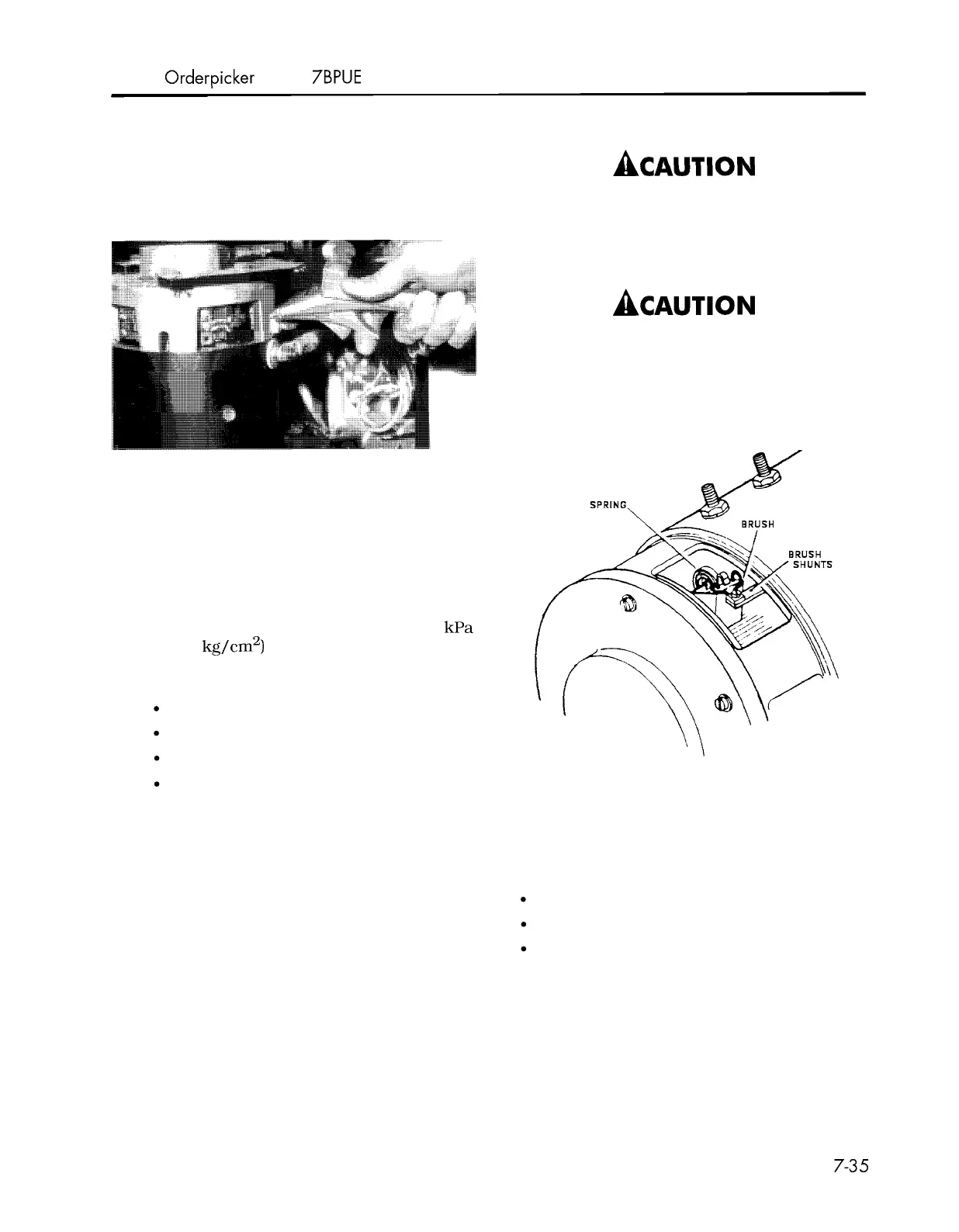

Figure 7

-

44. Motor Brush Location

Motor Brushes

Location

Drive motor brushes, see Figure 7

-

45.

Lift motor brushes, see Figure

7

-

46.

Steer motor brushes, see Figure 7

-

47.

Inspection

Conduct a partial inspection of the motor after

every 500 hours of truck operation. If you work

in an abnormally severe or caustic environment

or if you have a rigorous duty cycle, inspect the

motor more frequently.

00700

-

CL222

-

05,

1

5 March 2005

Loading...

Loading...