Section 7. Component Procedures

Toyota

Orderpicker Model 7BPUE 15 Service Manual

Motors (General)

Commutator

Electrical Components

terminal securing nut to avoid twisting the

stud.

Figure 7

-

50. View of Steer Motor Commutator

Inspection

The commutator should be inspected for

surface condition and high mica.

The commutator must be smooth and clean to

provide maximum brush wear. When

commutators are not properly maintained,

carbon dust can collect in the grooves between

the segments. This can lead to

a

short circuit in

the armature.

Good commutation will be indicated by a

dark

-

brown, polished commutator and an

evenly polished brush wearing surface.

If

the commutator appears rough, pitted, or has

signs of burning or heavy arcing between the

commutator bars, the motor should be removed

for servicing.

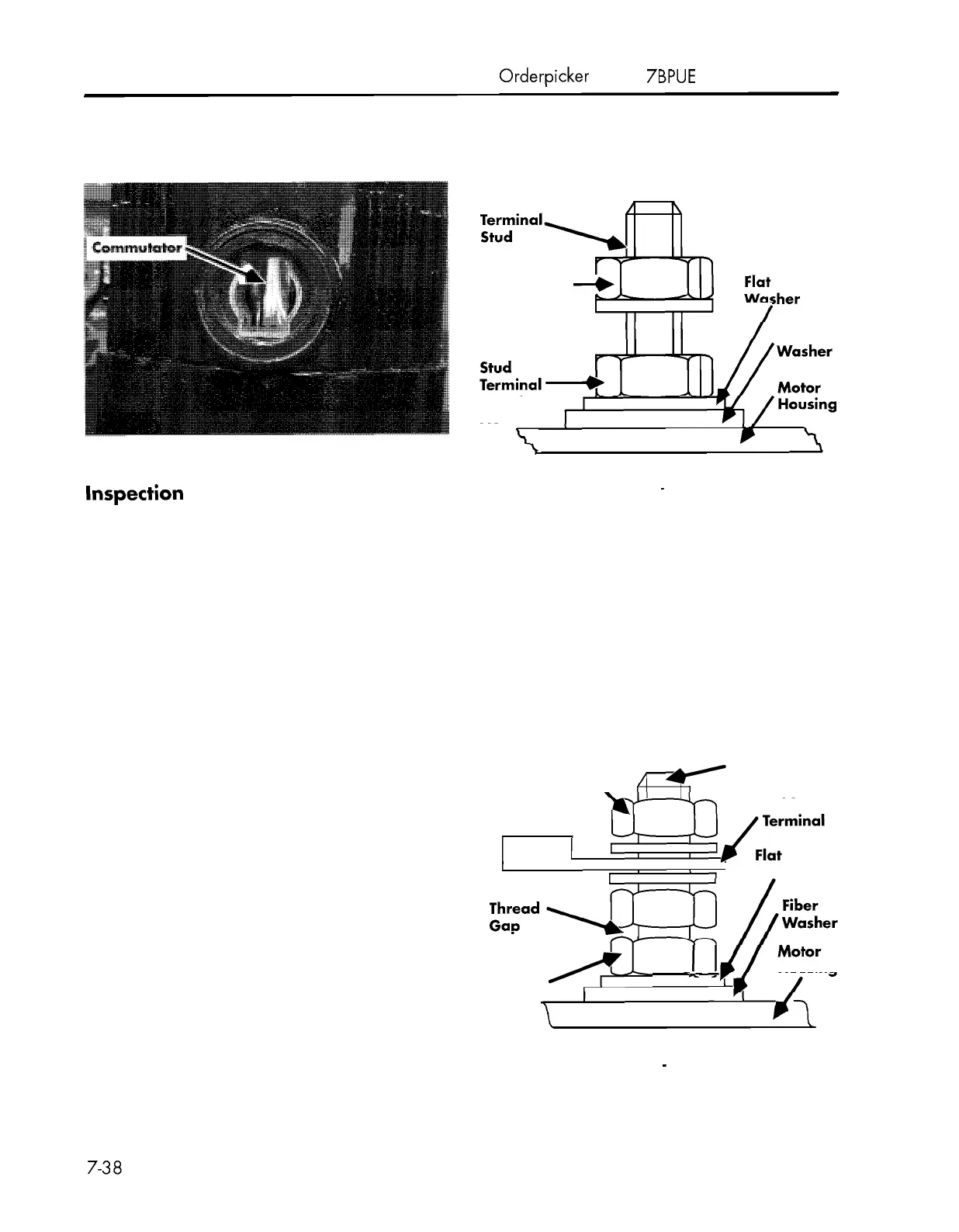

Terminal Nuts

Whenever you disconnect and reconnect any

power leads to a motor, always tighten the

motor cable securing nuts with a torque wrench

to prevent over

-

tightening them and damaging

the motor. Use a second wrench on the stud

Motor Cable

Securing Nut

Fiber

Securing

Nut

Figure

7

-

5

1.

Motor Terminal

-

Double Nut

Stud terminal securing nuts should be torqued

to 140

-

160 in. lbs. (15.8

-

18.1 Nm) and motor

cable securing nuts to 100

-

120 in. lbs.

(1 1.2

-

13.6 Nm). Check these torques each time

you check motor brushes.

Two different methods are used to connect

power leads on this truck. The double nut

method is shown in Figure 7

-

5 1. The triple nut

method is shown in Figure 7

-

52. The torques

listed in the paragraph above apply to both

methods.

Motor Cable

-

Terminal Stud

Securing Nut

\

Cable Lug

/Fzminal

I

Washer

1

or2

Stud

Terminal

&-

-

A

Housing

Securing

Nut

Figure 7

-

52.

Motor Terminal

-

Triple Nut

00700

-

CL222

-

05,

1

5

March 2005

Loading...

Loading...