Toyota Orderpicker Model 7BPUE 15 Service Manual Section 7. Component Procedures

Hydraulic Components Lift Pressure Relief Valve Adjustment

Lift Pressure Relief Valve

required to lift maximum rated load

(value recorded earlier).

Adjustment

b.

TO

increase pressure, turn adjusting

screw

clockwise. To decrease pressure,

turn adjusting screw

counterclockwise.

c. Tighten locknut on lift pressure relief

valve.

9. Check pressure again. If value has

changed, repeat this procedure until the

correct pressure reading is obtained.

10. Turn key switch OFF.

1 1. Disconnect pressure gauge and reinstall

cap on lift pressure test port

(Gl).

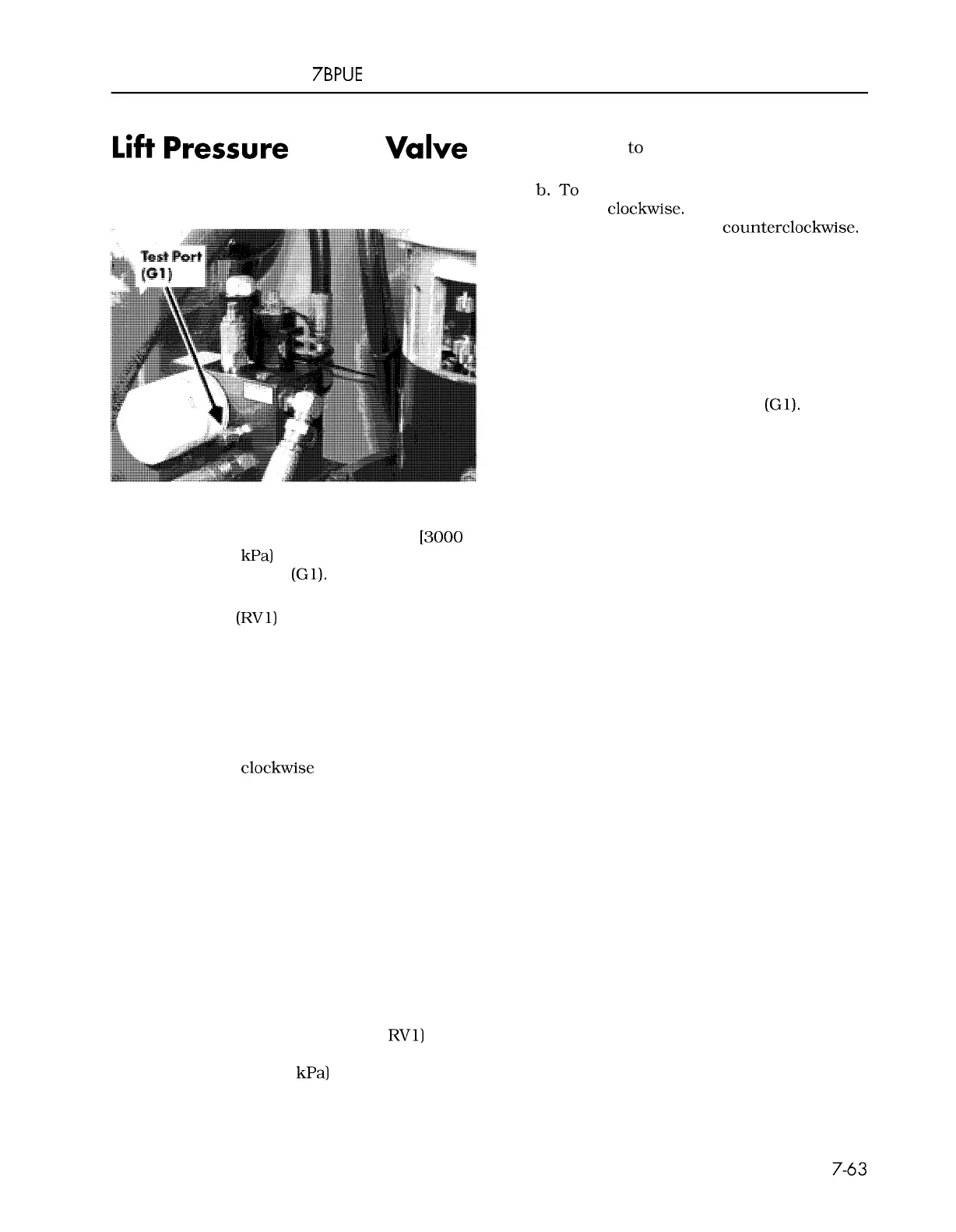

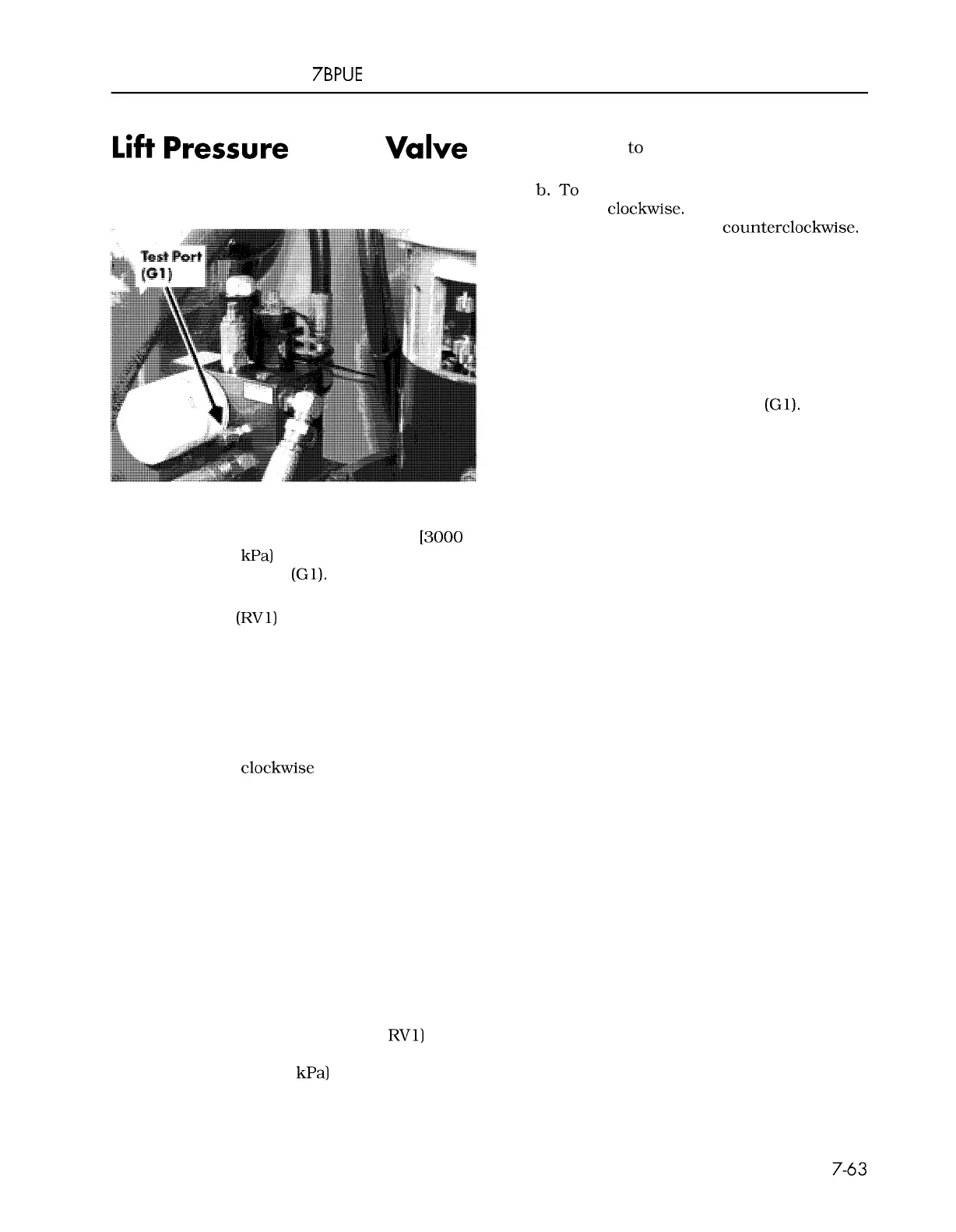

Figure

7

-

94.

Adjusting Lift Pressure

1. Install a calibrated pressure gauge [3000

psi (20,682 kPa) at mid

-

range] in the lift

pressure test port

(Gl). See Figure 7

-

94.

2. Loosen the locknut on the lift pressure

relief valve

(RV1) to back out the

high

-

pressure relief.

3.

Make sure emergency lower valve is

closed.

4. Place a maximum rated load

+

200 lb.

(90.7 kg.) on the forks.

5.

Start the lift system and turn the pressure

relief screw

clockwise until the platform

starts to lift. Note the pressure required

when the platform starts to elevate. On

three

-

stage trucks, continue lifting until

the third stage of the mast starts lifting.

Record the pressure reading.

6. Lower the operator platform and remove

the load.

7. Chain the mast sections together and lift

or lift the operator platform until the

upper limit is reached.

8.

To adjust pressure:

a. Continue trying to elevate, and turn lift

pressure adjusting screw (at

RV1) to

obtain a pressure reading of 100 to 300

psi (689 to 2068

kPa) greater than that

00700

-

CL222

-

05,

1

5 March 2005

Loading...

Loading...