Toyota Orderpicker Model 7BPUE

1

5 Service Man ual Section 7. Component Procedures

Electrical Components

If the end of the brush is not already contoured

to fit the commutator:

Figure 7

-

48. Motor Brush, Steer Motor

N

O

T

E

:

Form the brush contour using a brush

seating stone.

Spring

Scale

-

Rotation

\

Pull paper in direction of rotation

Motors (General)

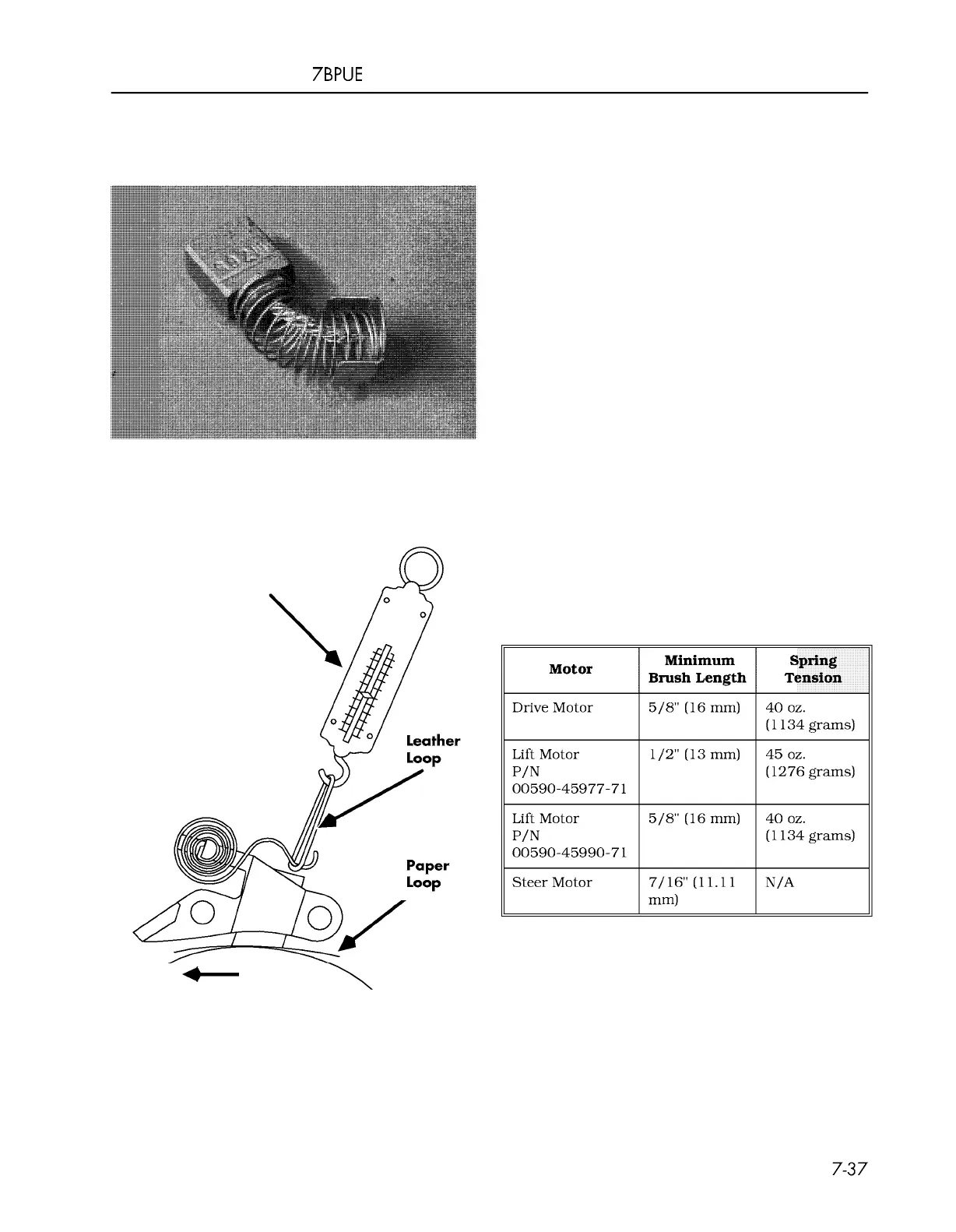

Motor Brush Spring Tension

Inspection

1.

Turn the key switch OFF and disconnect

the battery connector.

2.

Remove the tractor cover.

3.

Slide the brush up slightly in its holder.

4.

Insert a paper strip between the brush

face and the commutator.

5.

Place a small leather loop around the coil

spring for the brush. If the brush spring

has a loop at the brush, hook the spring

scale directly to the spring.

6.

Attach a

5

lb.

(2.27

kilogram) spring scale

to the leather loop.

7.

While gently pulling the scale outward,

slowly pull the paper strip in the direction

that the commutator normally rotates.

8.

When the paper strip begins to move

freely, the spring scale will read the spring

brush tension.

9.

Refer to the table below for proper spring

tension:

10.

Repeat steps

3

through

9

for the

remaining brushes.

Figure 7

-

49. Motor Brush Spring Tension Inspection

00700

-

CL222

-

05,

1

5 March 2005

Loading...

Loading...