ENGINE

3-4

EAS20472

ENGINE

EAS20520

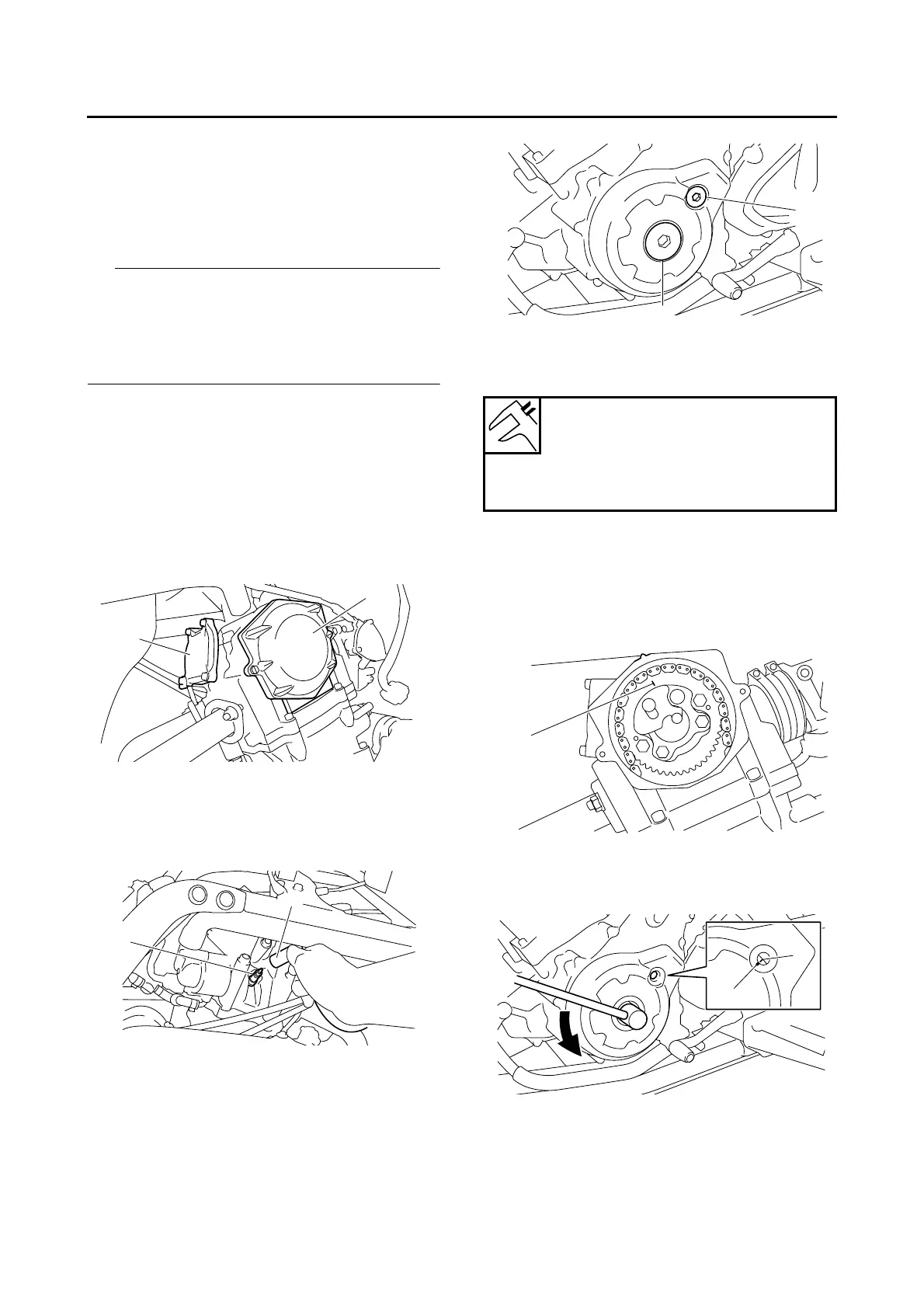

ADJUSTING THE VALVE CLEARANCE

The following procedure applies to all of the

valves.

IP

• Valve clearance adjustment should be made

on a cold engine, at room temperature.

• When the valve clearance is to be measured or

adjusted, the piston must be at top dead center

(TDC) on the compression stroke.

1. Remove:

• Seat

• Front fender

• Fuel tank

Refer to “GENERAL CHASSIS” on page 4-1.

2. Remove:

• Intake tappet cover

• Exhaust tappet cover “1”

• Camshaft sprocket cover “2”

3. Disconnect:

• Spark plug cap “1”

4. Remove:

• Spark plug “2”

5. Remove:

• Timing mark accessing screw “1”

• Crankshaft end accessing screw “2”

6. Measure:

• Valve clearance

Out of specification → Adjust.

▼▼▼▼▼▼▼▼▼ ▼ ▼▼▼▼ ▼ ▼▼▼▼ ▼ ▼▼▼▼ ▼ ▼▼▼▼ ▼▼▼

a. Turn the crankshaft counterclockwise.

b. When the piston is at TDC on the compres-

sion stroke, align the punch mark “a” in the

camshaft sprocket with the stationary pointer

“b” on the cylinder head.

c. Align the TDC mark “c” on the AC magneto

rotor with the stationary pointer “d” on the AC

magneto cover.

d. Measure the valve clearance with a thickness

gauge “1”.

Out of specification → Adjust.

2

1

2

1

Valve clearance (cold)

Intake

0.09–0.13 mm (0.0035–0.0051 in)

Exhaust

0.16–0.20 mm (0.0063–0.0079 in)

1

2

b

a

c

d

Loading...

Loading...