GENERAL INFORMATION

1-15

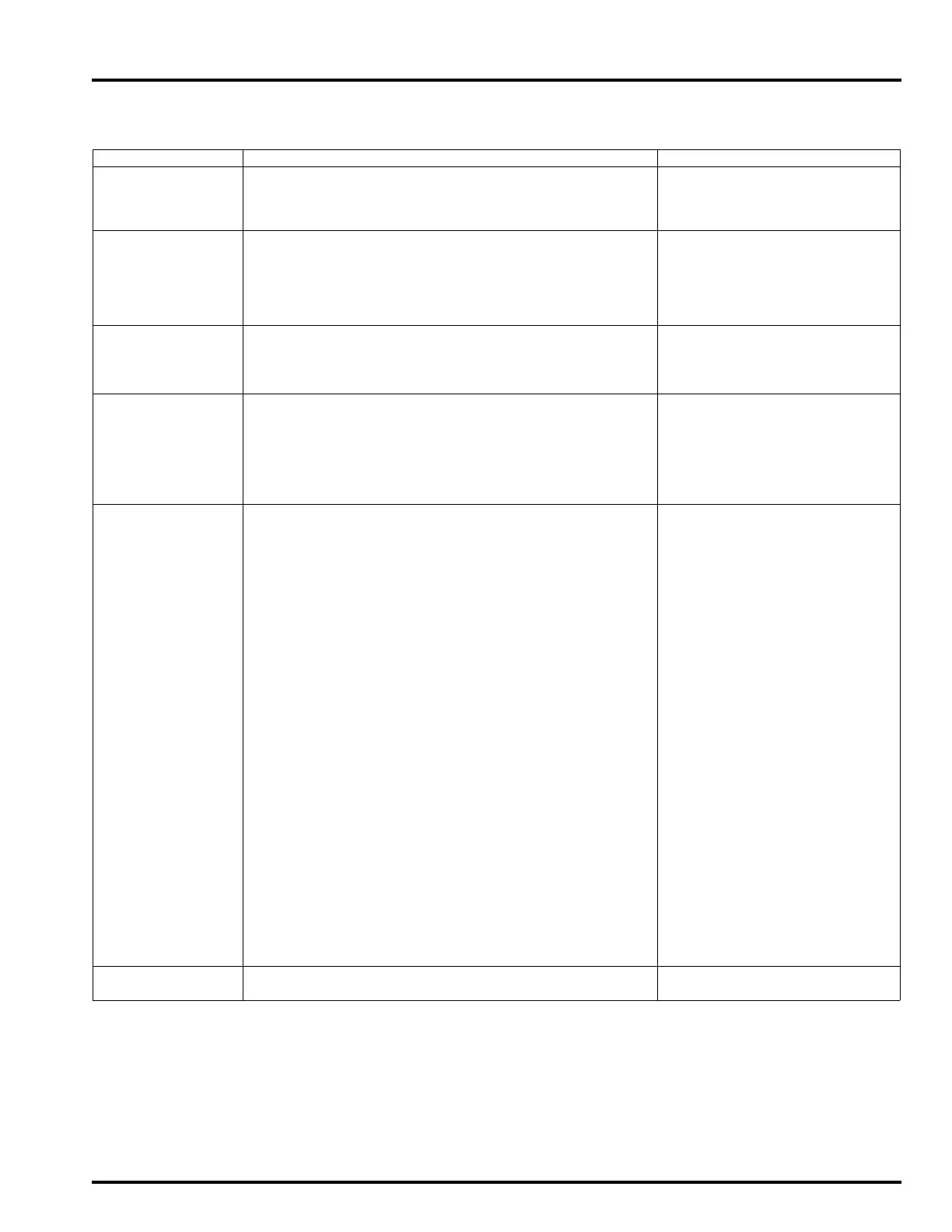

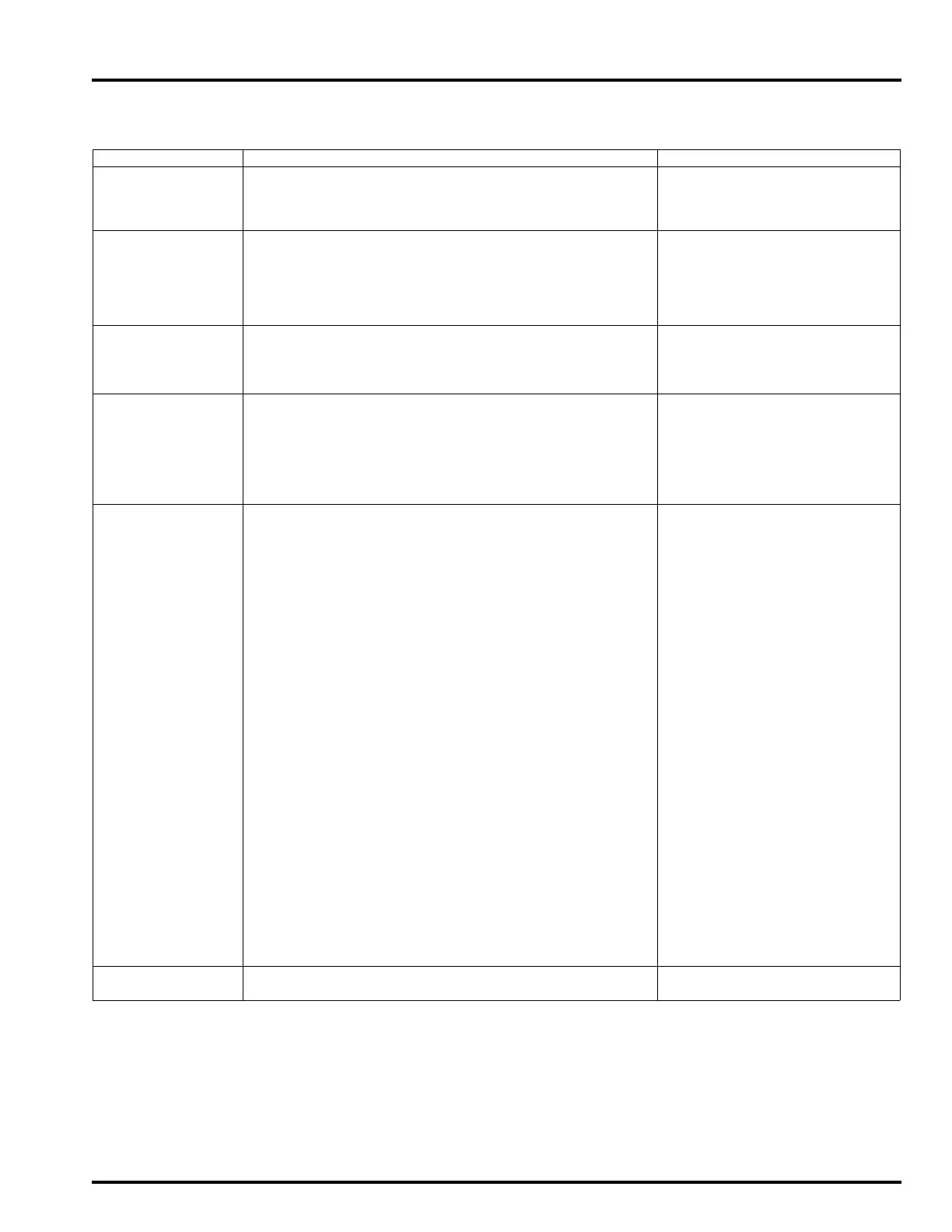

LUBRICATION & SEAL POINTS

ENGINE

MATERIAL LOCATION REMARKS

Liquid sealant

(recommended:

Three Bond 1215

or equivalent)

Right crankcase mating surface See page 14-9

Final reduction case/breather hose grommet mating sur-

face

See page 12-14

Molybdenum

disulfide oil (a

mixture of 1/2

engine oil and 1/2

molybdenum

disulfide grease)

Camshaft cam lobes

Multi-purpose

grease

Driven face needle bearing

Driven face ball bearing

Crankcase main stand pivot area

Movable driven face oil seal lip

Grease (Shell

ALVANIA R3 or

SHIN-NIHON

POWERNOC WB3

or IDEMITSU

AUTOREX B or

equivalent)

Driven face inner surface 7 – 8 g

Movable driven face guide groove 2.0 – 2.5 g

Starter pinion gear shaft (both end) 0.1 – 0.3 g

Engine oil (With-

out molybdenum

additives)

Oil pump rotor whole surface

Oil pump shaft and teeth

Water pump chain whole surface

Water pump shaft and driven gear teeth

Washer surface of the camshaft holder nut

Cylinder stud bolt threads (camshaft holder side)

Rocker arm shaft sliding surface

Rocker arm roller sliding area

Camshaft bearing

Cam sprocket teeth

Cam chain whole surface

Valve stem (valve guide sliding area)

Valve stem seal inner surface

Piston, piston ring and cylinder sliding surfaces

Piston pin outer surface

Oil pump drive gear teeth of crankshaft

Timing sprocket teeth of crankshaft

Connecting rod small end inner surface

Crankshaft bearings Fill up 2 cc minimum

Connecting rod big end bearing Fill up 3 cc minimum

Bearing area of drive, counter and final shaft

Drive, counter and final gear teeth

Ball/needle bearing sliding area

Each O-ring whole surface (Except coolant passage)

Oil seal lips and outer surfaces

Water pump bearing

Fuel pump packing Apply 1.0 g max

Degrease Right crankshaft tapered area

Drive/driven pulley face and drive belt

Loading...

Loading...