1-S58

BX24, RCK54(P)-23BX, RCK60B-23BX, LA240, BT601, WSM

ENGINE

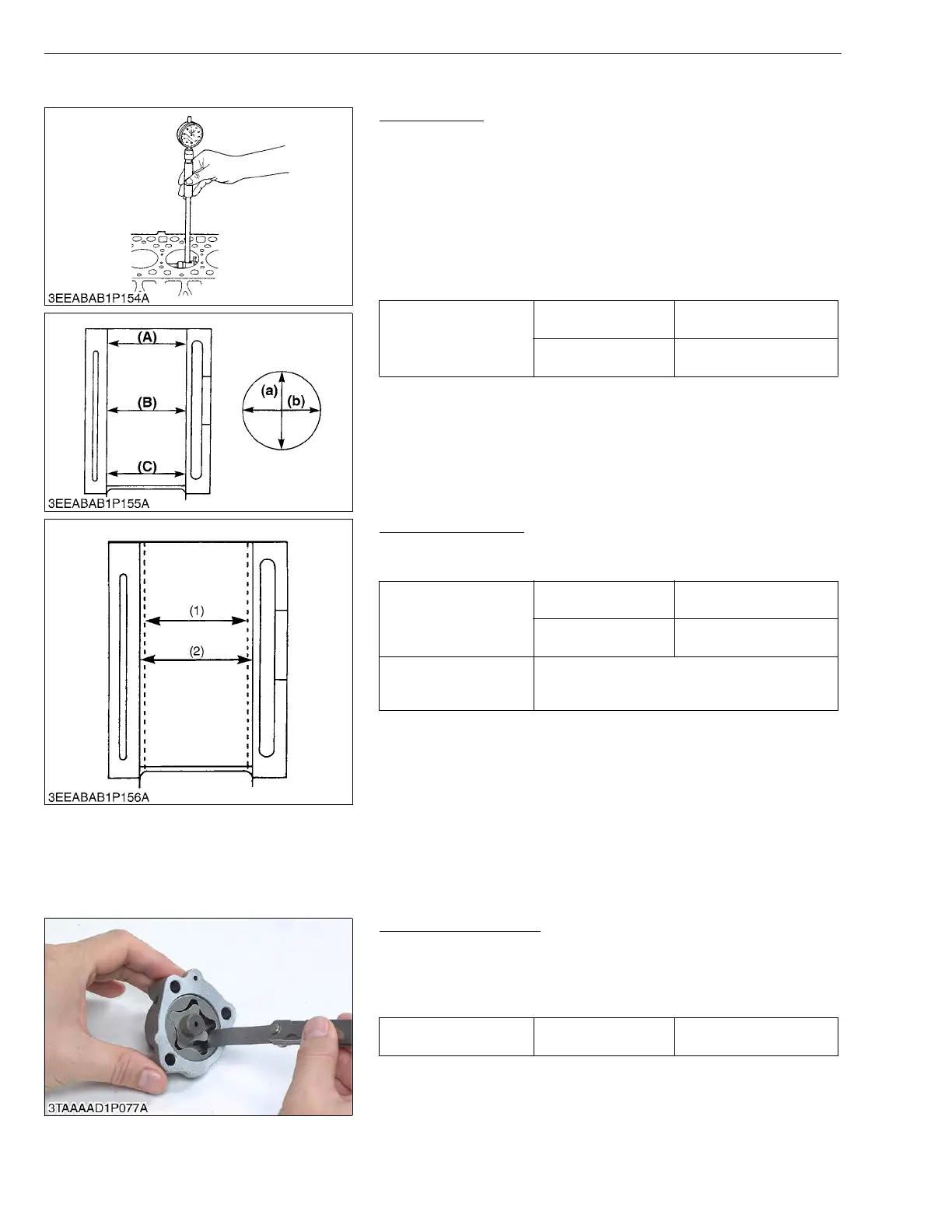

(5) Cylinder

Cylinder Wear

1. Measure the cylinder liner I.D. at the six positions (see figure)

with a cylinder gauge to find the maximum and minimum I.D.’s.

2. Get the difference (Maximum wear) between the maximum and

the minimum I.D.’s.

3. If the wear exceeds the allowable limit, bore and hone to the

oversize dimension. (Refer to “Correcting Cylinder”.)

4. Visually check the cylinder wall for scratches. If deep scratches

are found, the cylinder should be bored. (Refer to “Correcting

Cylinder”.)

W10360060

Correcting Cylinder

1. When the cylinder is worn beyond the allowable limit, bore and

hone it to the specified dimension.

2. Replace the piston and piston rings with oversize ones.

Oversize : 0.25 mm (0.0098 in.)

Marking : 025

• When the oversize cylinder is worn beyond the allowable

limit, replace the cylinder block with a new one.

W10367470

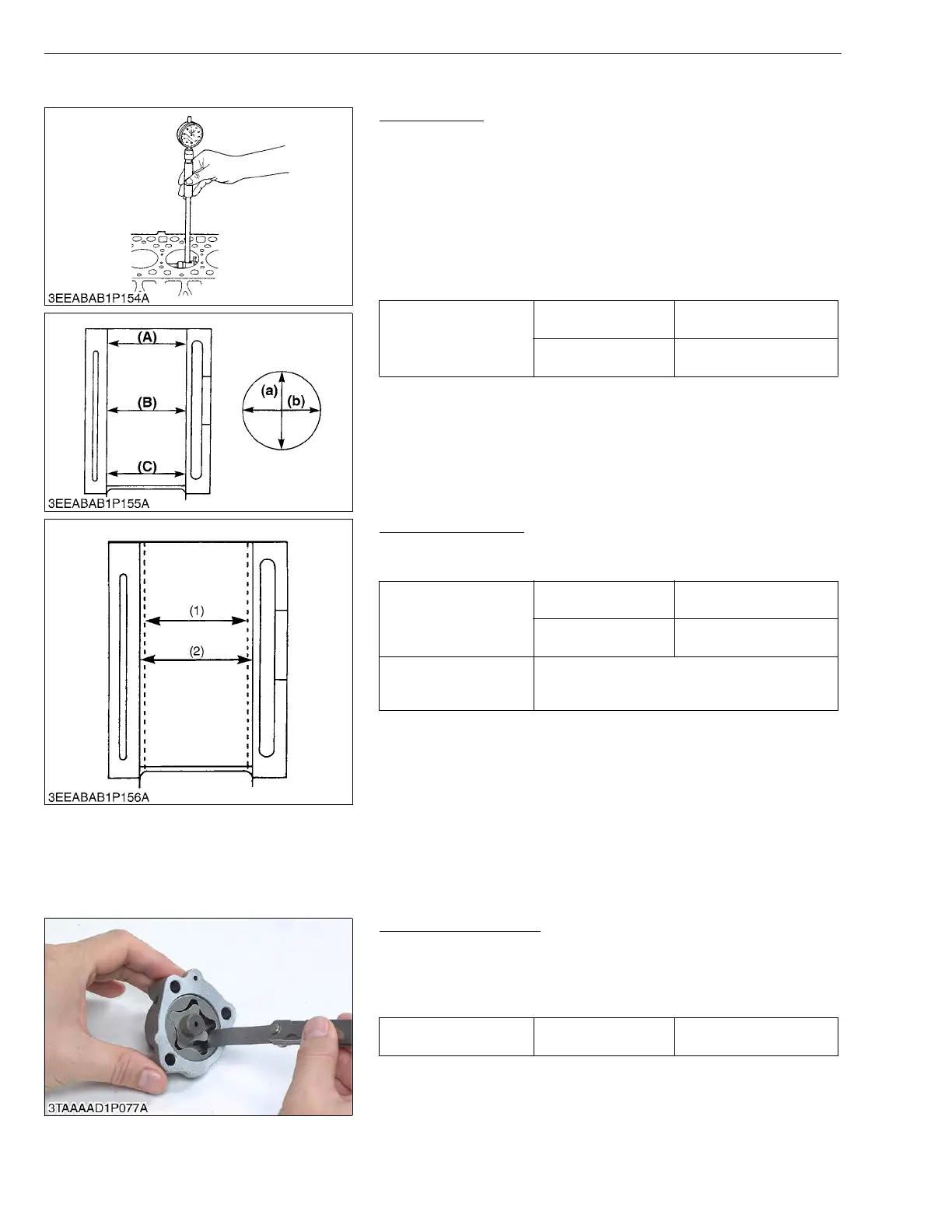

(6) Oil Pump

Rotor Lobe Clearance

1. Measure the clearance between lobes of the inner rotor and the

outer rotor with a thickness gauge.

2. If the clearance exceeds the factory specifications, replace the oil

pump rotor assembly.

W10378950

Cylinder liner I.D.

Factory spec.

72.000 to 72.019 mm

2.83464 to 2.83539 in.

Allowable limit

72.150 mm

2.84055 in.

(A) Top

(B) Middle

(C) Bottom (Skirt)

(a) Right-angled to Piston Pin

(b) Piston Pin Direction

Cylinder liner I.D.

Factory spec.

72.250 to 72.269 mm

2.84449 to 2.84524 in.

Allowable limit

72.400 mm

2.85040 in.

Finishing

Hone to 2.2 to 3.0 mRz.

(0.000087 to 0.00012 in.Rz)

(1) Cylinder I.D. (Before Correction) (2) Cylinder I.D. [Oversize]

Rotor lobe clearance Factory spec.

0.03 to 0.14 mm

0.0012 to 0.0055 in.

Loading...

Loading...