Maintenance

5-2

P/N 7105144G

2008 Nordson Corporation

VersaBlue_NW

Processing Materials

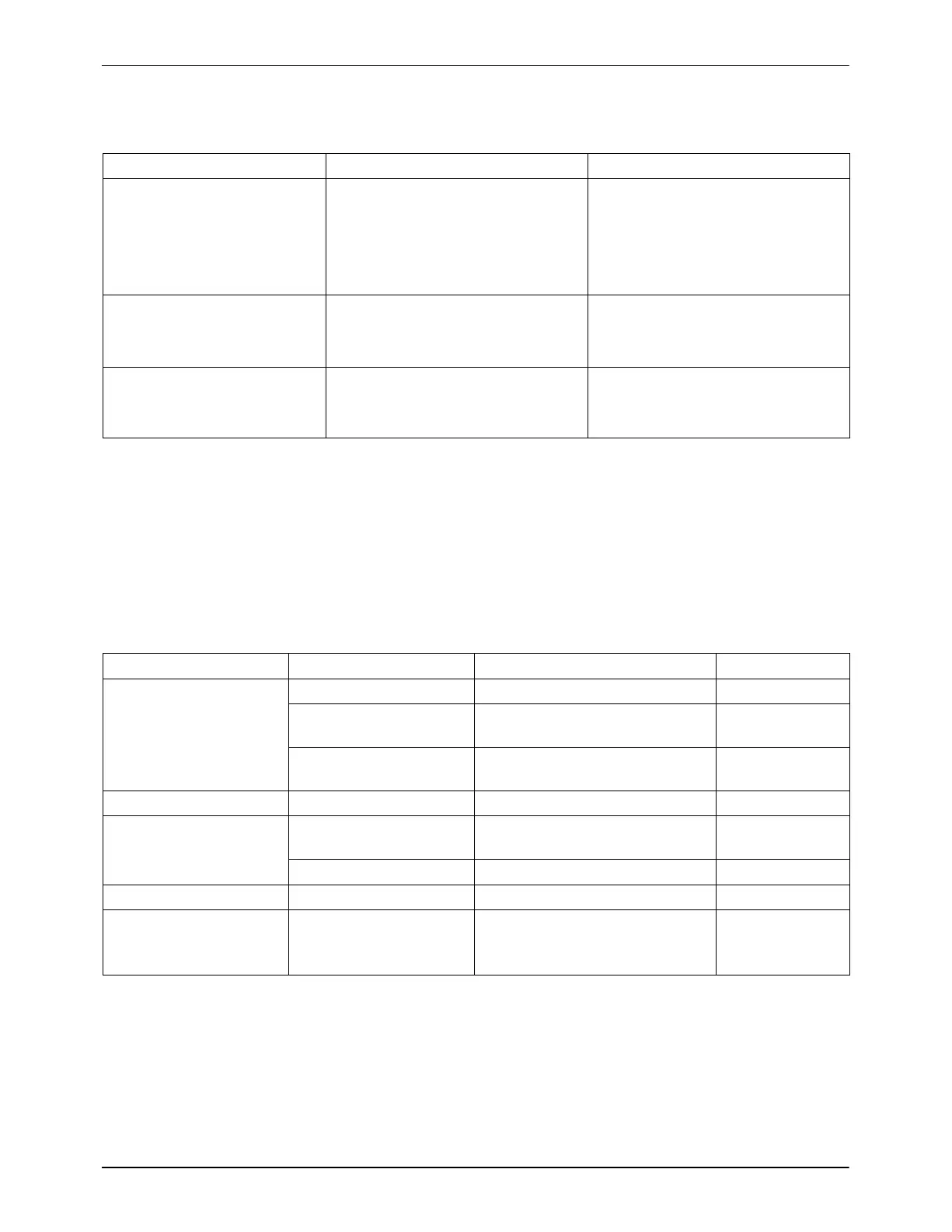

Designation Order number Use

High temperature grease To be applied to O-rings and

threads

NOTE: The grease may not be

mixed with other lubricants.

Oily/greasy parts must be cleaned

before application.

Can 10 g

P/N 394 769

Tube 250 g

P/N 783 959

Cartridge 400 g

P/N 402 238

Temperature-resistant

adhesive Loctite 640

Secures screw connections

50 ml

P/N 290 359

Heat transfer compound

NTE303

To improve heat conducting of

temperature sensors

1 g

P/N 1023441

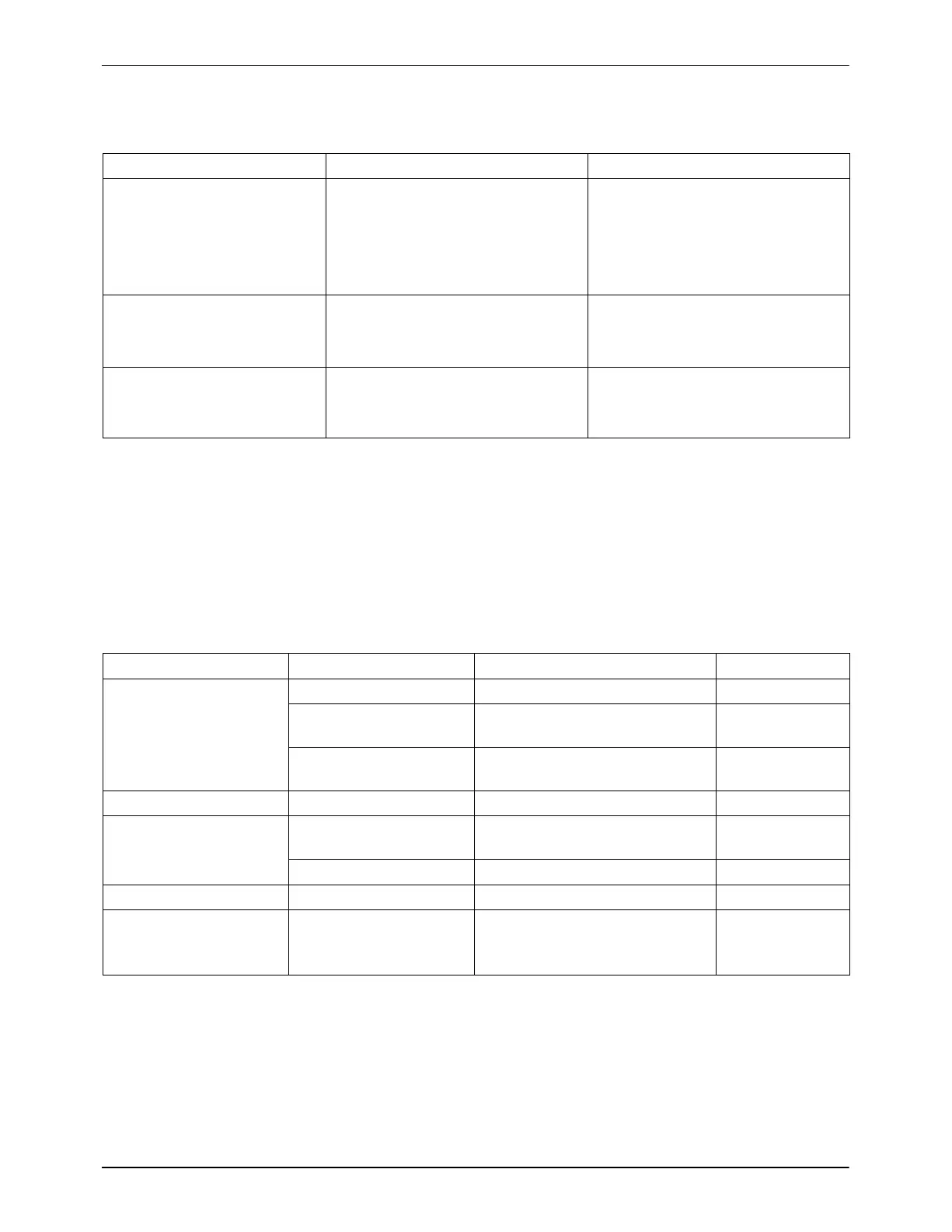

Preventive Maintenance

The maintenance intervals are general guidelines based on experience.

Depending on the operating environment, production conditions and melter

hours of operation, other scheduled maintenance tasks may prove

necessary.

NOTE: Coupling and motor controller are maintenance-free.

Melter part

Activity Interval Refer to

Complete melter External cleaning Daily 5-4

Inspect for external

damage

Daily 5-5

Purge melter with

cleaning agent

When material is changed 5-6

Displays and lamps Safety and function tests Daily 5-5

Tank Clean tank by hand When there is material residue in

tank

5-6

Tighten fixing screws Every 500 hours of operation 5-6

Safety valve Activate piston Monthly 5-6

Fan and

Air filter

Check filter, clean or

replace if necessary

Clean fan screen

Depending on dust

accumulation; daily if necessary

5-8

Loading...

Loading...