1

2

3

2

1

1

Introduction

2-7

P/N 7105144G

2008 Nordson Corporation

VersaBlue_NW

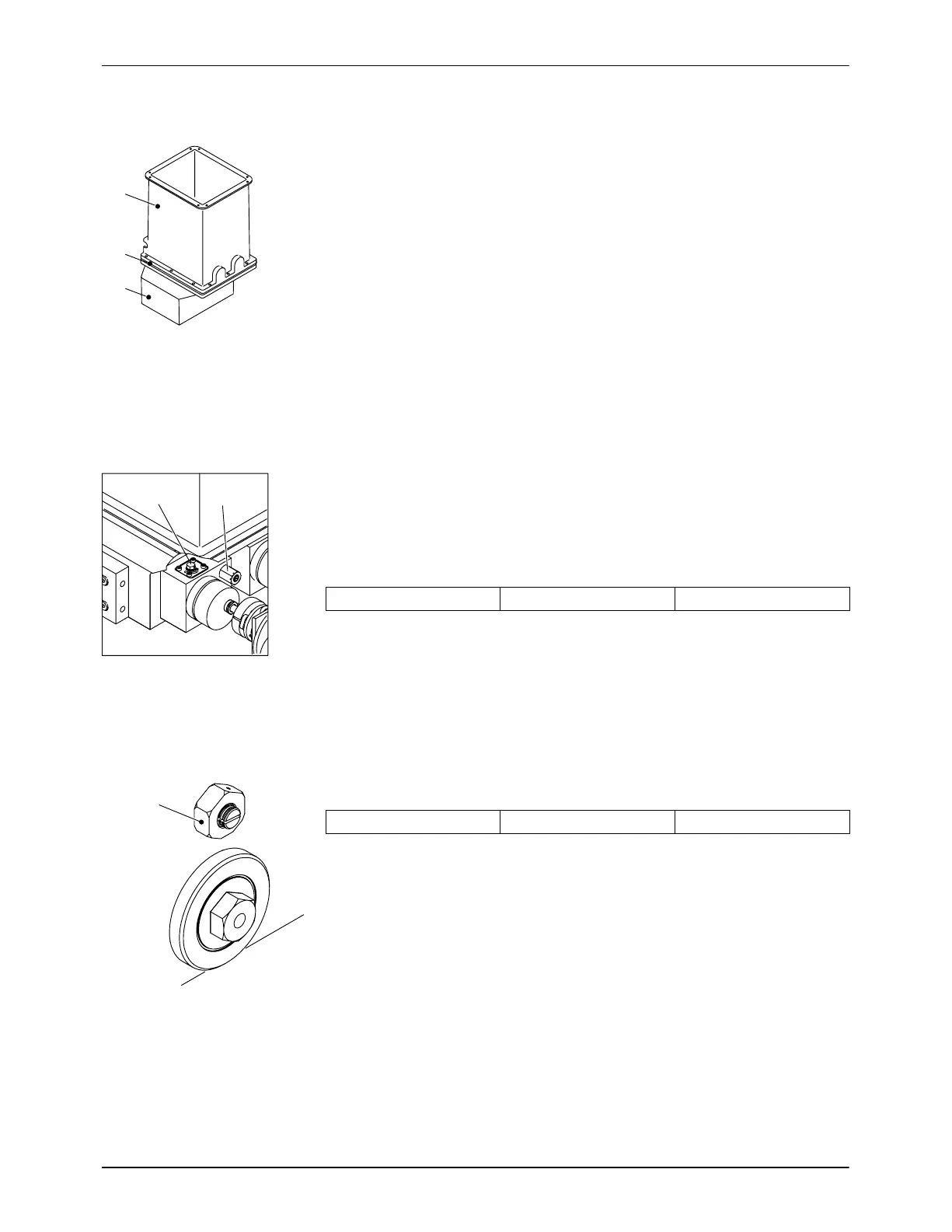

Tank

The tank is divided into grid (low melt) and reservoir (high melt) sections. An

insulating seal (2) provides a temperature barrier between the two sections.

The temperature barrier allows the material in the grid section (1) to be

gently melted at a low temperature. The material is then melted to

processing temperature in the reservoir (3).

Fig. 2-2

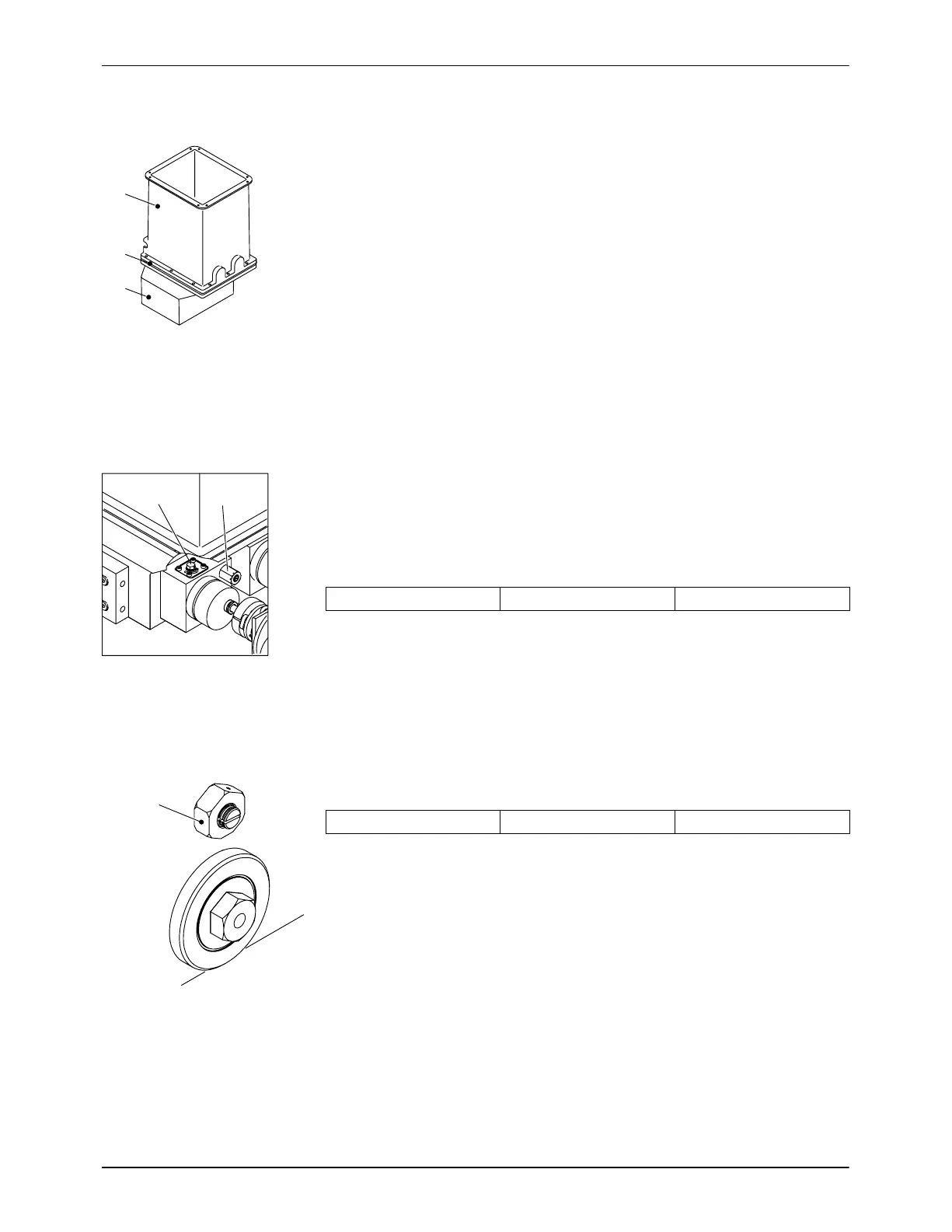

Safety Valve Plate

Tank Isolation Valve

The tank isolation valve (1) enables replacement of the gear pump without

first emptying the tank.

Safety Valve

The standard safety valve (2) is fixed at

8500 kPa

85 bar 1235 psi

When the pressure is exceeded, the safety valve opens, allowing the

material to circulate within the safety valve plate.

Fig. 2-3

Mechanical Pressure Control Valve

The mechanical pressure control valves (1) are built into the manifold above

the filter cartridge. They can be adjusted manually within the range of

500 to 9000 kPa

5 to 90 bar 72.5 to 1305 psi

One pressure control valve per pump is standardly installed after the filter

cartridge.

Fig. 2-4

Loading...

Loading...