Rockwell Automation Publication 2198-UM005C-EN-P - February 2022 219

Appendix C Motor Control Feature Support

Speed Limited Adjustable

Torque (SLAT)

Speed limited adjustable torque (SLAT) is a special mode of operation used

primarily in web handling applications. While configured for SLAT, the drive

typically operates as a torque regulator. The drive can automatically enter

velocity regulation based on conditions within the velocity regulator and the

magnitude of the velocity regulator's output, relative to the applied

TorqueTrim attribute.

A torque regulated application can be described as any process requiring

tension control. For example, a winder or unwinder with material being drawn

or pulled with a specific tension required. The process also requires that

another element set the speed.

When operating as a torque regulator, the motor current is adjusted to achieve

the desired torque. If the material being wound or unwound breaks, the load

decreases dramatically and the motor can potentially go into a runaway

condition.

The SLAT feature is used to support applications that require a robust

transition from torque regulation to velocity regulation (and vice versa). The

SLAT feature can be configured via the SLATConfiguration attribute as:

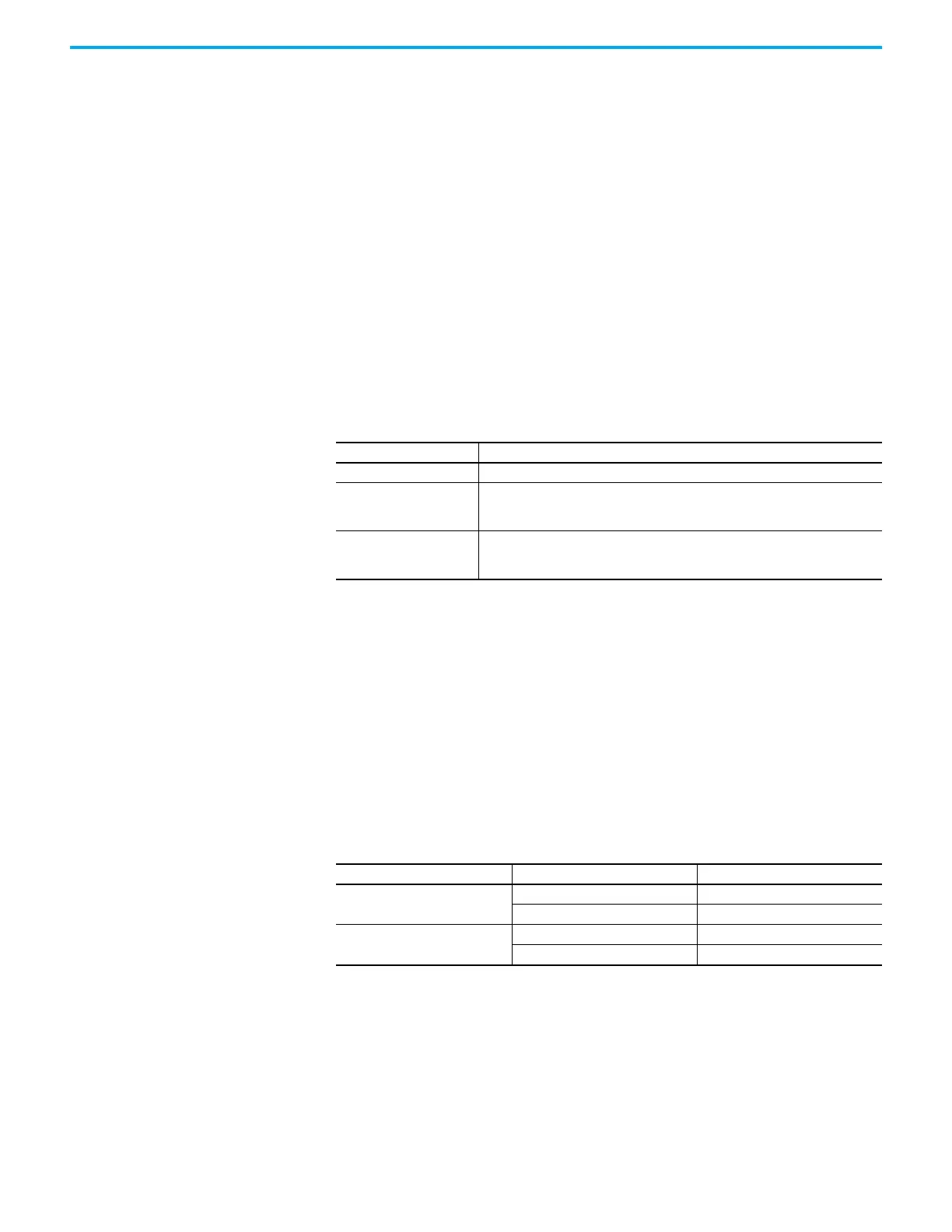

Table 100 - SLAT Configuration Descriptions

Direction of the applied torque and direction of the material movement

determine whether SLAT minimum or SLAT maximum mode should be used.

Motion Polarity Setting

The Motion Polarity setting in the Logix Designer application>Axis

Properties>Polarity does not affect SLAT behavior, however, you may require

clarification on whether to use the SLAT Min Speed/Torque or SLAT Max

Speed/Torque configuration when Motion Polarity is set to Inverted. In this

case, the velocity error displayed in the Logix Designer application is inverted

compared to what is actually used by the axis to control the SLAT function. So,

if the SLAT configuration is set to Min and then Motion Polarity is switched to

Inverted, change the SLAT configuration to Max.

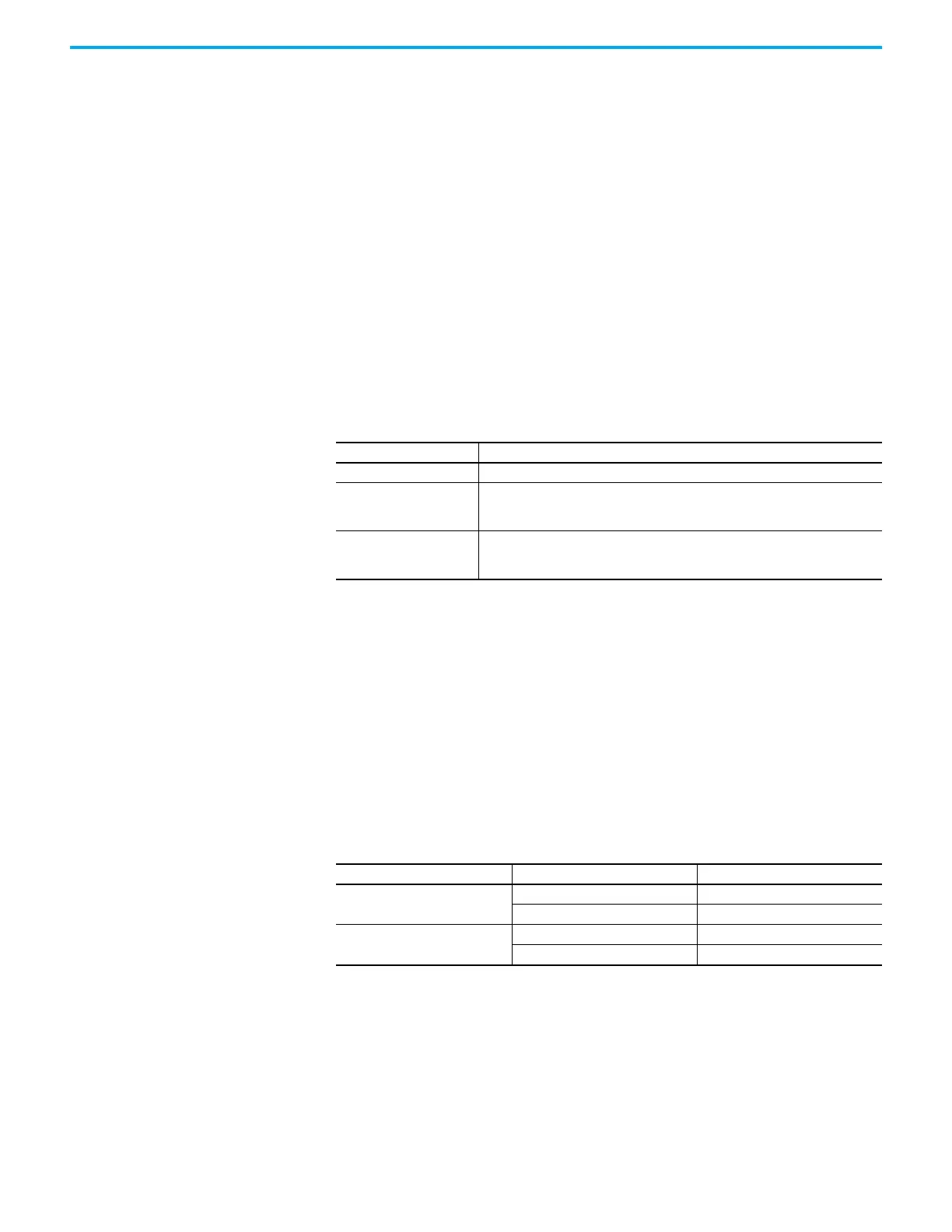

Table 101 - SLAT Operation When Motion Polarity Is Inverted

SLAT Min Speed/Torque

SLAT Min Speed/Torque is a special mode of operation primarily used in web

handling applications. The drive typically operates as a torque regulator,

provided that the TorqueTrim attribute is less than the torque output due to

the velocity regulator's control effort. The drive can automatically enter

velocity regulation based on conditions within the velocity regulator and the

magnitude of the velocity regulator's output relative to the torque reference.

Name Description

SLAT Disable SLAT function is disabled. Normal Velocity Loop operation.

SLAT Min Speed/Torque

Drive automatically switches from Torque regulation to Velocity regulation if

VelocityError < 0 and switches back to Torque regulation if VelocityError > SLATSetPoint

for SLATTimeDelay.

SLAT Max Speed/Torque

Drive automatically switches from Torque regulation to Velocity regulation if

VelocityError > 0 and switches back to Torque regulation if VelocityError < SLATSetPoint

for SLATTimeDelay.

Velocity Command Motion Polarity SLAT Configuration

Positive (clockwise)

Normal Min

Inverted Max

Negative (CCW)

Normal Min

Inverted Max

Loading...

Loading...