Rockwell Automation Publication 2198-UM005C-EN-P - February 2022 71

Chapter 5 Connect the Kinetix 5300 Drive System

Ground the Drive System All equipment and components of a machine or process system must have a

common earth ground point connected to chassis. A grounded system

provides a ground path for protection against electrical shock. Grounding your

drives and panels minimize the shock hazard to personnel and damage to

equipment caused by short circuits, transient overvoltages, and accidental

connection of energized conductors to the equipment chassis.

Ground the System Subpanel

Ground Kinetix 5300 drives to a bonded cabinet ground-bus with a braided

ground strap of at least 10 mm

2

(0.0155 in

2

) in cross-sectional area. Keep the

braided ground strap as short as possible for optimum bonding.

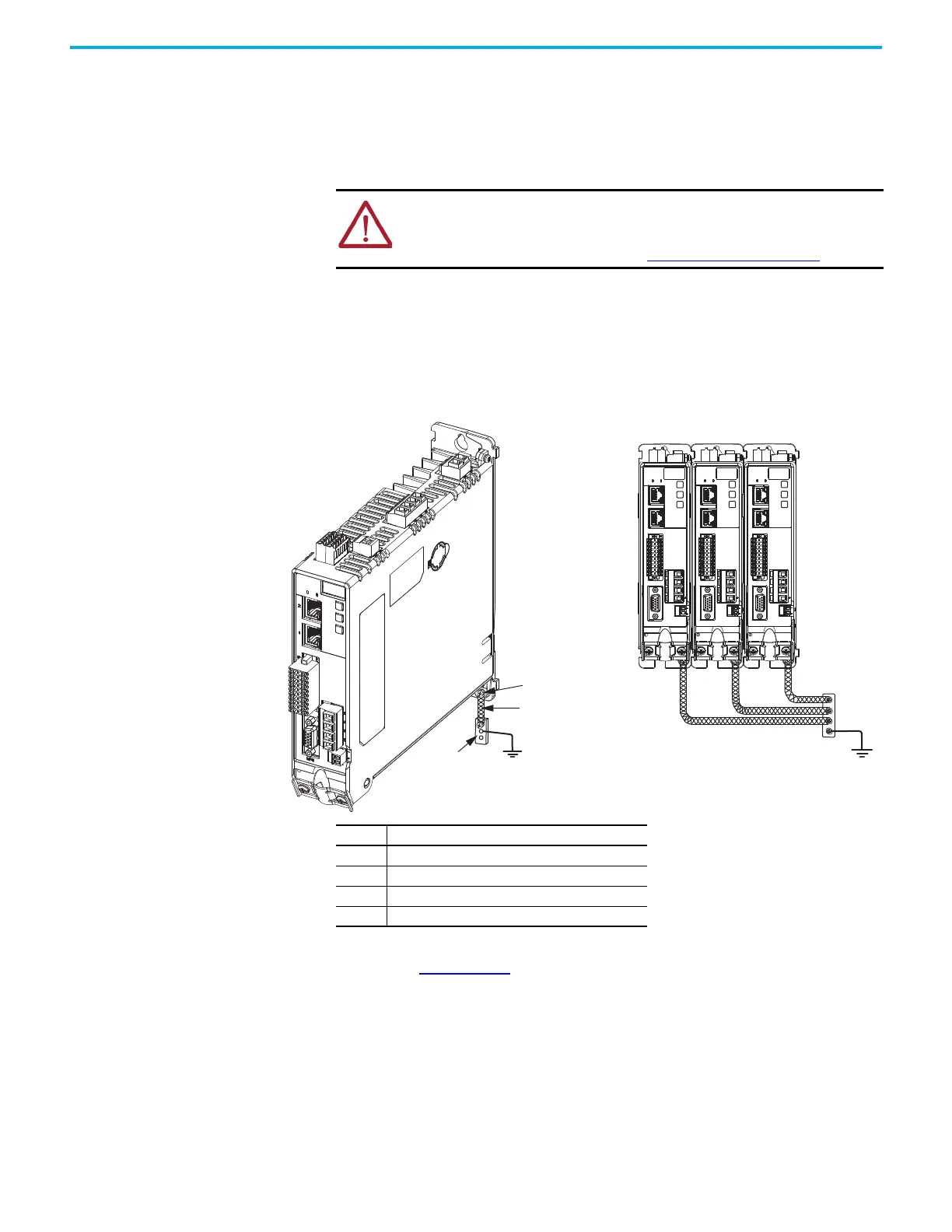

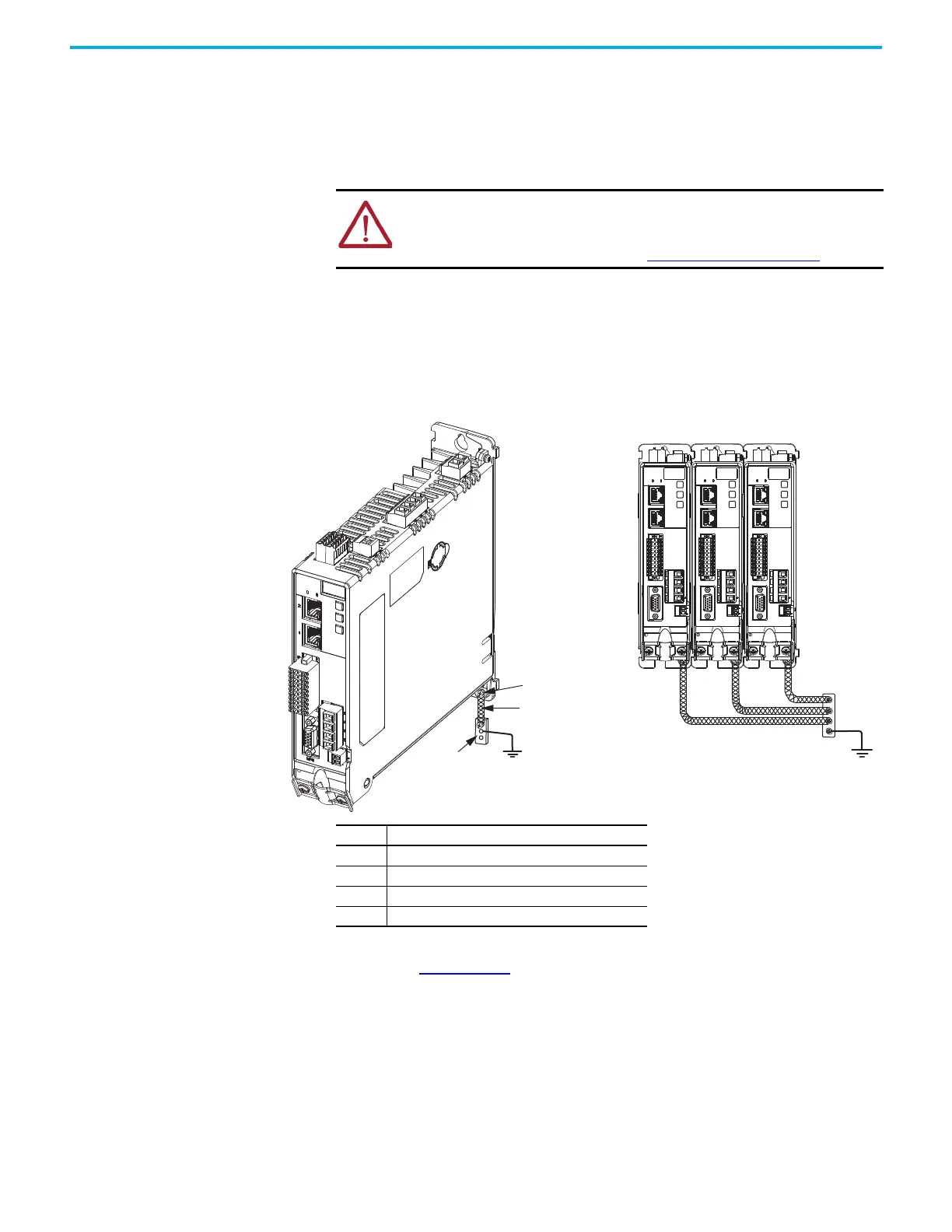

Figure 36 - Connect the Ground Terminal

Refer to the System Design for Control of Electrical Noise Reference Manual,

publication GMC-RM001, for more information.

ATTENTION: The National Electrical Code contains grounding requirements,

conventions, and definitions. Follow all applicable local codes and regulations to

safely ground your system.

For CE grounding requirements, refer to Agency Compliance

on page 24.

MBRK

W

V

U

1

10

1

2

MFB

MBRK

W

V

U

1

10

1

2

MFB

MBRK

W

V

U

1

10

1

2

MFB

Make braided ground straps

with at least 10 mm

2

(0.0155 in

2

)

cross-sectional area.

Keep straps as short as possible.

4

3

2

1

Kinetix 5300

Servo Drive

(standalone)

Kinetix 5300

Servo Drives

(zero-stack)

Item Description

1 Ground screw (green) 2.0 N•m (17.7 lb•in), max

2 Braided ground strap (customer supplied)

3 Ground grid or power distribution ground

4 Bonded cabinet ground bus (customer supplied)

Loading...

Loading...