Short instructions for configuring a reversing starter

SIMOCODE pro

GWA 4NEB 631 6050-22 DS 03

2-7

General procedure for parameterizing a reversing starter

Parameterization means:

1. Setting values

2. Connecting function blocks

Where this example is concerned, this means:

• Select the control function "Reversing Starter". This establishes all the

interlocks and connections for the reversing starter in the basic unit.

• Determine the set current I

s

for motor protection. In this case, the set current

corresponds to the motor rated current, i.e. 3 A.

• The "BU Outputs" function block must be connected to the sockets of the

"Protection/Control" function block via the software, i.e:

– "BU Output 1" plug to "Contactor Control QE1" socket (right)

– "BU Output 2" plug to "Contactor Control QE2" socket (left).

• The plugs on the "Protection/Control" function block must be connected via

software to the sockets on the "BU Inputs" function block, i.e.

– Control station plug - Local Control [LC] ON< to "BU Input 1" socket

– Control station plug - Local Control [LC] OFF to "BU Input 2" socket

– Control station plug - Local Control [LC] ON> to "BU Input 3" socket.

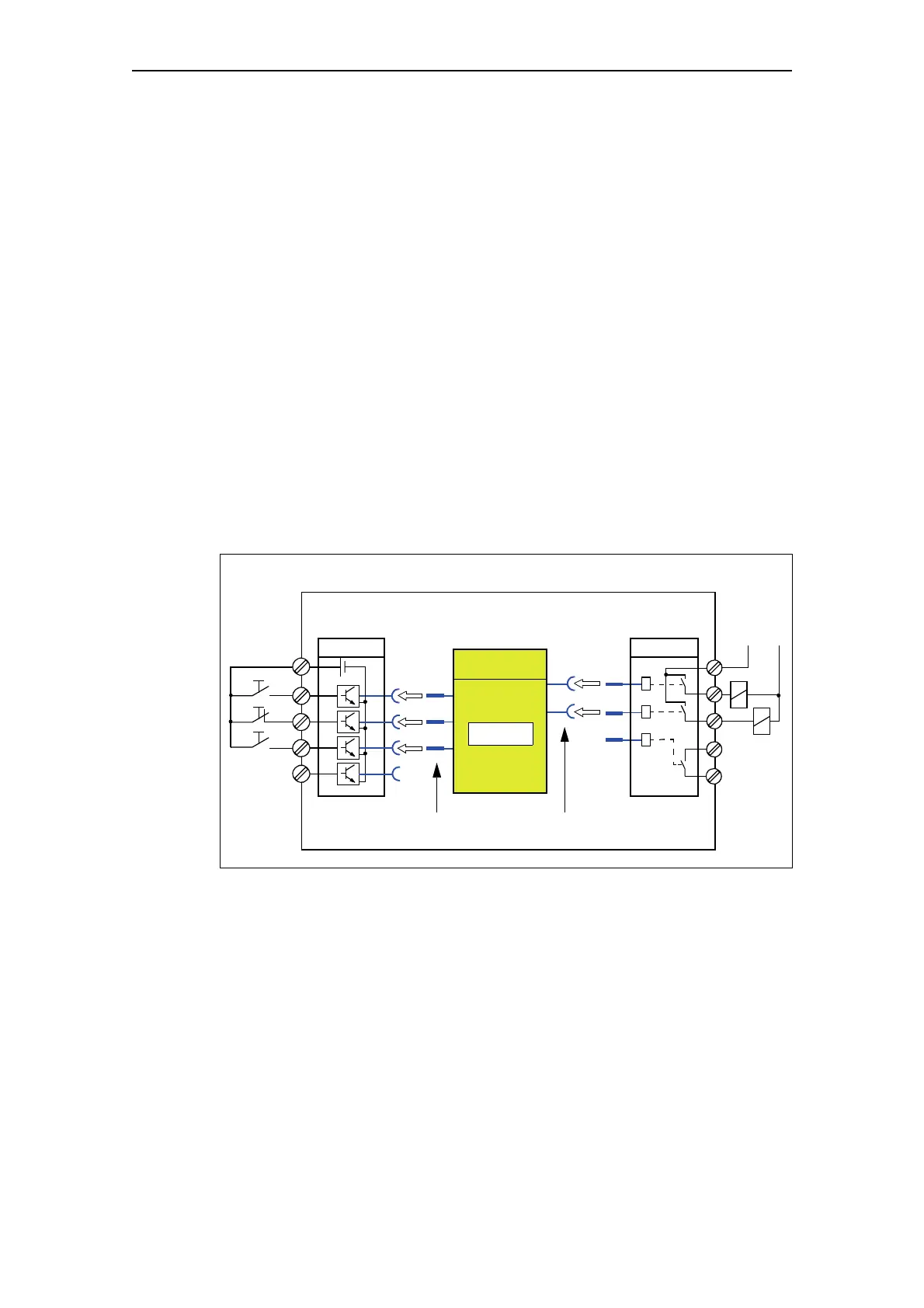

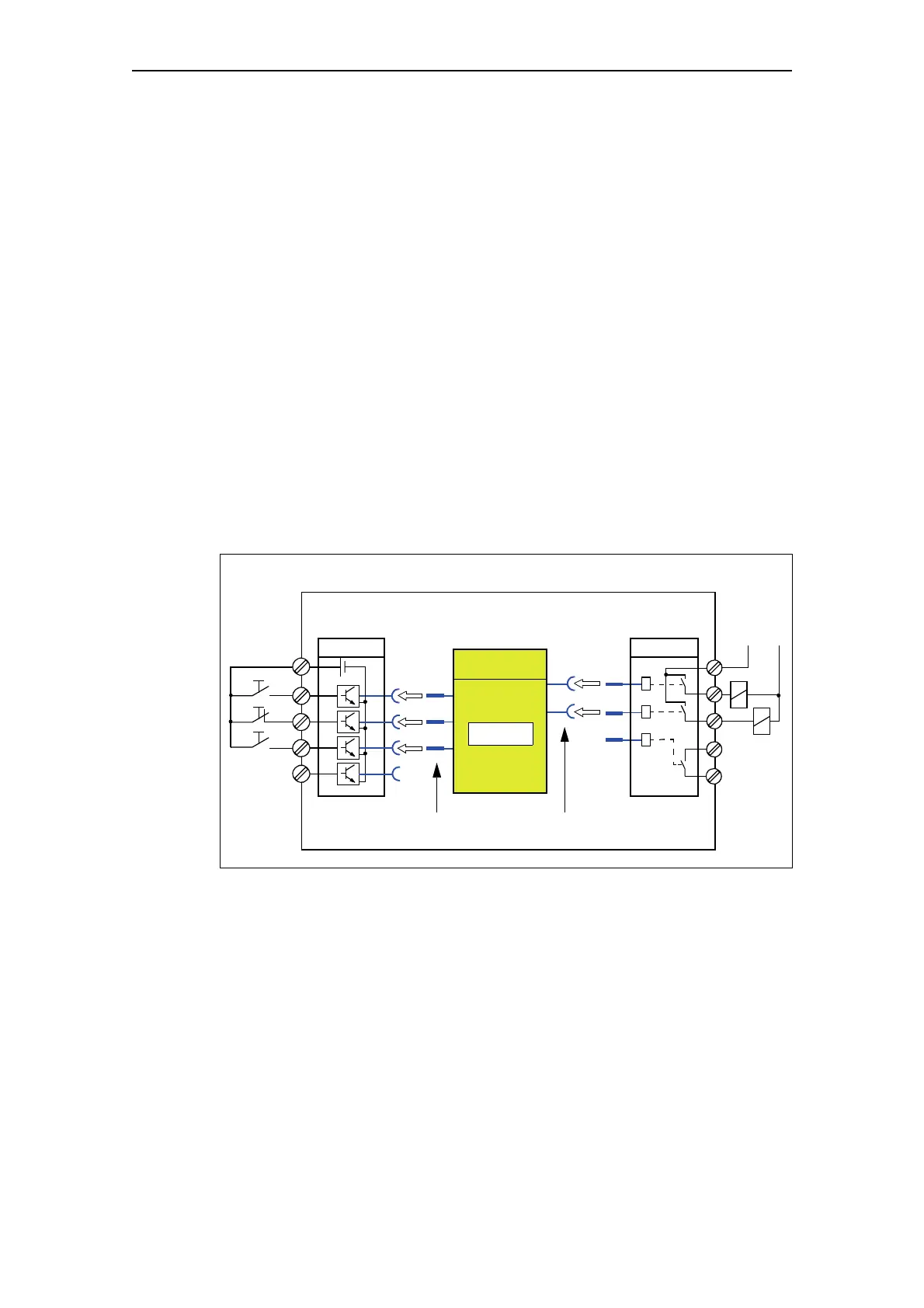

Fig. 2-3: Schematic of a parameterization example

The assignment of the contactor controls QE depends on the parameterized

control function. See Chapter 4.3 "Active control stations, contactor

controls, lamp controls and status information for the control functions".

SIMOCODE pro

• Connect

relay outputs

1

2

1

2

3

BU Inputs

Control station - Local Control [LC] Contactor controls

• Select reversing starter

• Set I

s

• Connect

digital inputs

BU Outputs

QE1

QE2

ON<

OFF

ON>

Protection/Control

I

s

= 3 A

Right

Left

Loading...

Loading...