om 5184516-100 Rev. 5 9-10

Only service personnel specifically trained on medical x-ray equipment should

work on or maintain this equipment.

SECTION 6

LABELING

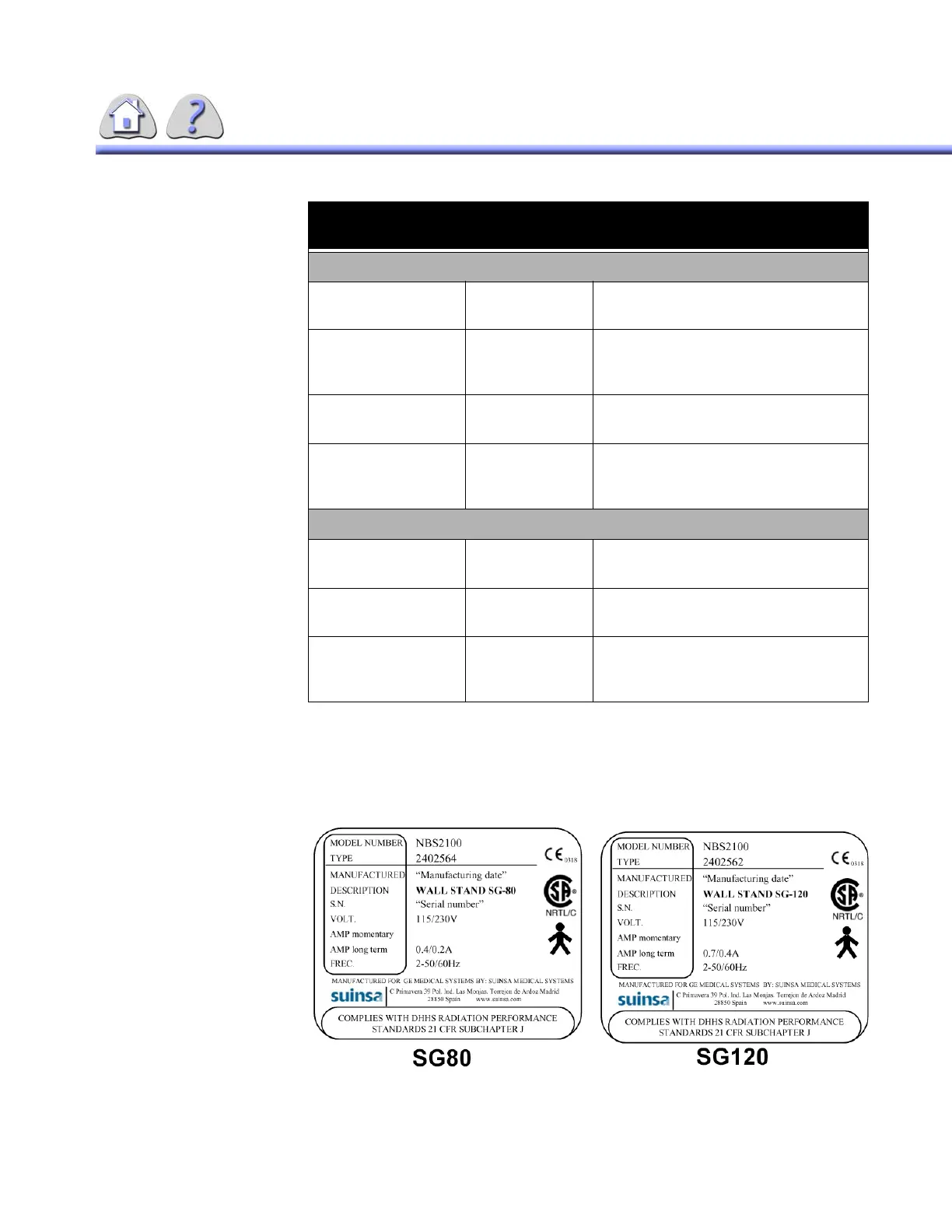

MAINTENANCE

ITEM

FREQUENCY

(MONTHS)

PROCEDURE

GENERAL

Visual Inspection 18 Check for debris that would indicate

abnormal wear

General cleaning

and painting

As required Wipe exterior parts using soft cloth,

water and mils soap. Vacuum interior

if any dust or lints is present

Functional checks 18 Perform tasks described in SG80/

120 Service Manual

Electrical checks 18 Inspect and replace any damaged

cables or connectors. Check ground-

ing

MECHANICAL

Counterweight

chain

18 Inspect and grease length of chains.

Replace if excessively rusty

Carriage roller bear-

ing inspection

18 Clear roller bearing and tracks

Vertical lock 18 Lock notched rail. General cleaning.

Functional check (see Service Man-

ual)

FOR TRAINING PURPOSES ONLY!

NOTE: Once downloaded, this document is UNCONTROLLED, and therefore may not be the latest revision. Always confirm revision status against a validated source (ie CDL).

Loading...

Loading...