8.7.5 Motor speed monitoring

This funcon monitors the motor speed during operaon.

Precondions

•

In order to detect the current motor speed, the inverter must be enabled and the motor

must rotate.

•

For an exact monitoring, rated motor speed 0x2C01:004 (P320.04) and rated motor fre-

quency 0x2C01:005 (P320.05) must be set correctly.

Details

•

If the motor speed reaches the threshold set in 0x2D44:001 (P350.01), the response set in

0x2D44:002 (P350.02) takes place.

•

With the seng 0x2D44:002 (P350.02) = "No response [0]", the monitoring funcon is

deacvated.

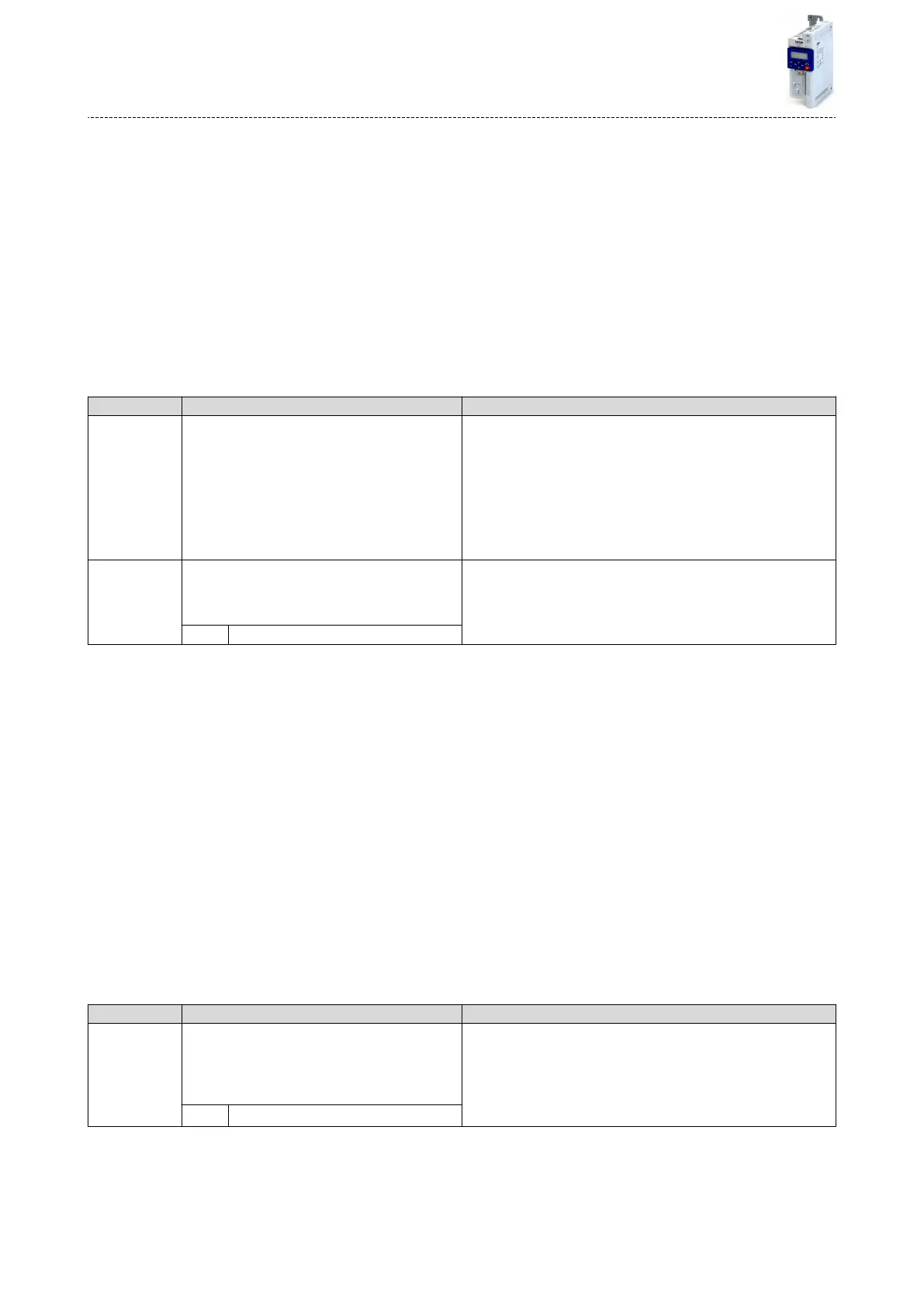

Parameter Name / value range / [default seng] Info

0x2D44:001

(P350.01)

Overspeed monitoring: Threshold

(Overspeed monit.: Threshold)

50 ... [8000] ... 50000 rpm

Warning/error threshold for motor speed monitoring.

•

If the motor speed reaches the threshold set, the response selected in

0x2D44:002 (P350.02) is eected.

•

The parameter is calculated and set in the course of the automac

idencaon of the motor.

•

The parameter can also be set and thus overwrien by selecng a

motor in the engineering tool from the "motor catalog" or calibrang

the motor.

4Opmisaon of the control loops ^ 140

0x2D44:002

(P350.02)

Overspeed monitoring: Response

(Overspeed monit.: Response)

•

For further possible sengs, see parameter

0x2D45:001 (P310.01). ^ 169

Selecon of the response to the triggering of motor speed monitoring.

Associated error code:

•

65286 | 0xFF06 - Motor overspeed

3 Fault

8.7.6 Motor torque monitoring

This funcon monitors the motor torque during operaon.

Precondions

The motor torque monitoring can only be used for the following motor control types with

speed controller:

•

Sensorless control (SL PSM)

•

Sensorless vector control (SLVC)

Details

This funcon sets the internal status signal "Torque limit reached [79]" = TRUE if the maximum

possible torque has been reached.

•

The status signal is set irrespecve of the response 0x2D67:001 (P329.01) and delay me

0x2D67:002 (P329.02) set for this monitoring.

•

The user can use the status signal to acvate certain funcons. 4Flexible I/O congura-

on ^ 344

•

The status signal also serves to set a digital output or a bit of the NetWordOUT1 status

word. 4

Conguraon of digital outputs ^ 415

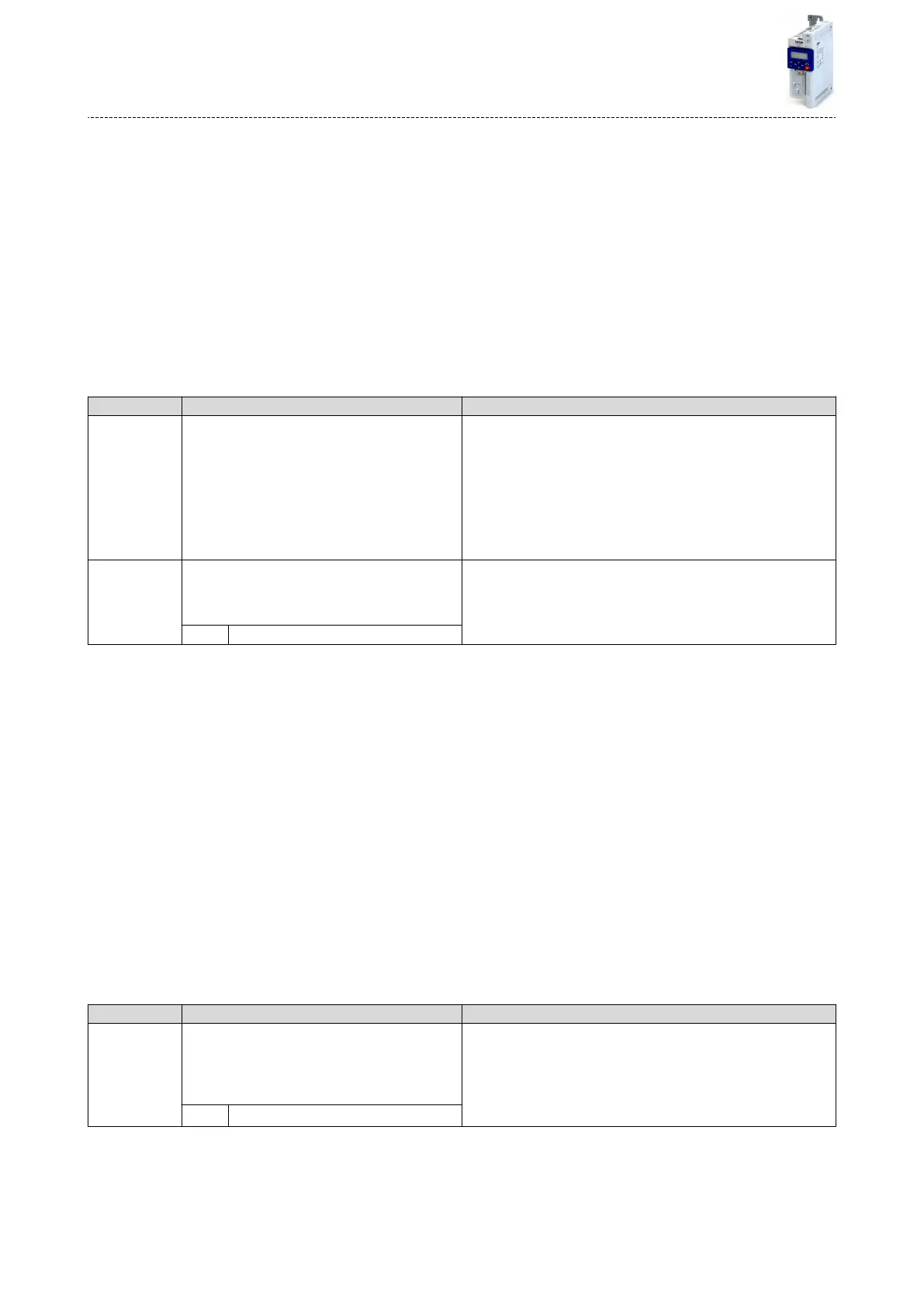

Parameter Name / value range / [default seng] Info

0x2D67:001

(P329.01)

Maximum torque monitoring: Response

(MaxTrq.Monitor: Response)

•

From version 02.00

•

For further possible sengs, see parameter

0x2D45:001 (P310.01). ^ 169

Selecon of response to reaching the maximum possible torque.

•

The selected response takes place if the status signal "Torque limit

reached [79]" = TRUE and the deceleraon me set in 0x2D67:002

(P329.02) has elapsed.

Associated error code:

•

33553 | 0x8311 - Torque limit reached

0 No response

Motor control

Motor protecon

Motor speed monitoring

170

Loading...

Loading...