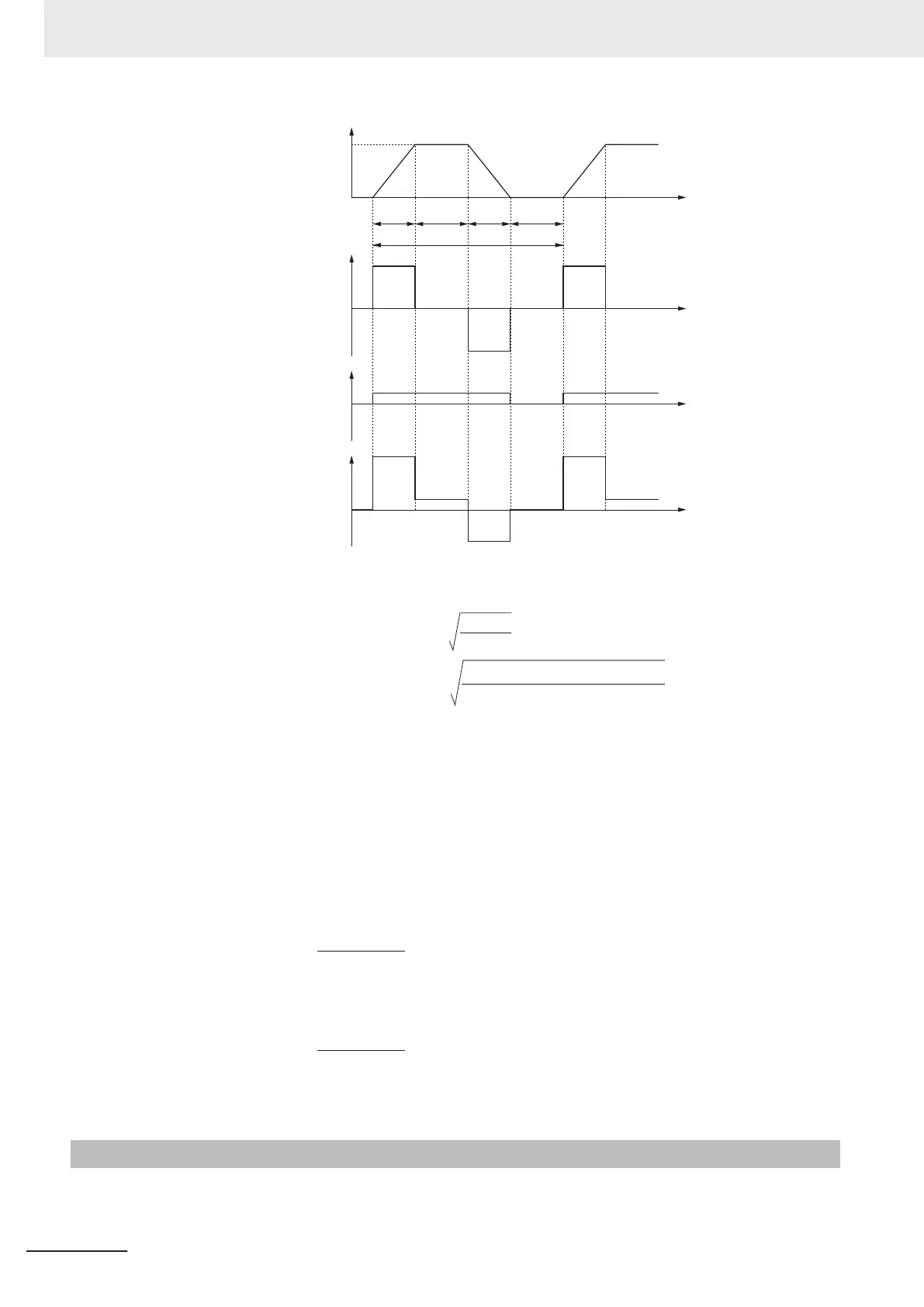

[r/min]

Time

[N·m]

Time

t1 t2 t3 t4

0

Acceleration/

Deceleration

torque

Rotation

speed

[N·m]

Time

0

Load

torque

TA

Combined

torque

Time

0

T1

TL

T2

T3

T4

N

1 cycle

[N·m]

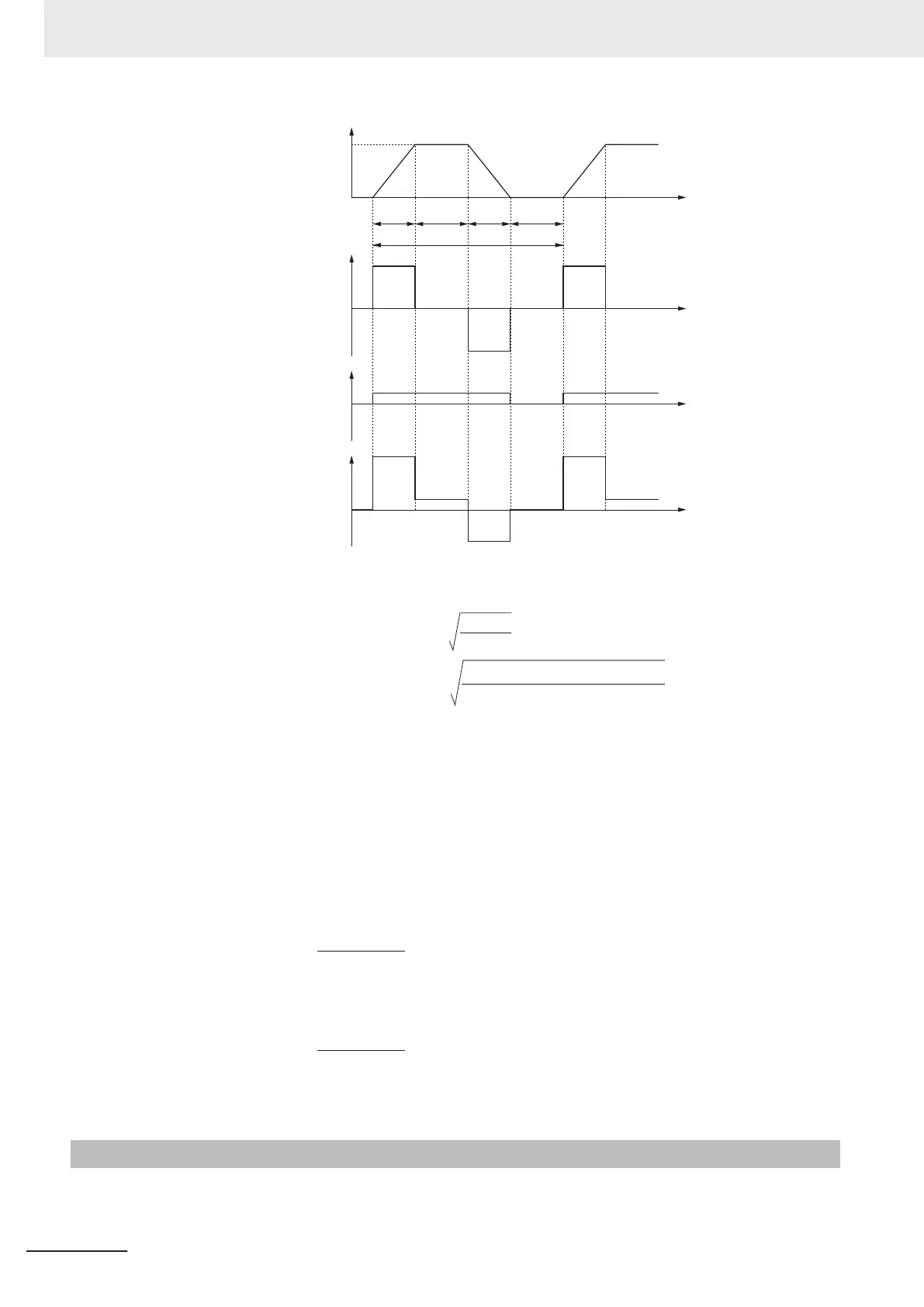

• Effective torque T

RMS

[N·m]

TR

MS[N·m]

=

=

Σ(Ti

2

·ti)

Σ

ti

T1

2

·t1 + T2

2

·t2 + T3

2

·t3 + T4

2

·t4

t1

+ t2 + t3 + t4

• Maximum torque T

MAX

[N・m] = T

1

= T

A

+T

L

Motor selection

Based on the above calculation results, select the motor capacity by using the following formulae.

Select the larger of the two calculated values as the motor capacity. Also, when selecting a motor

,

take into consideration the errors in calculation and modeling. Select a motor whose capacity is at

least approximately 20% larger.

• Motor capacity conversion to effective torque

Motor capacity [kW] = × 10

-3

60

2

π · T"#$ · N

N : Maximum rotation speed [r/min]

• Motor capacity required for maximum torque output

Motor capacity [kW] = × 10

-3

60 × 1.5

2

π · T"#$ · N

N : Maximum rotation speed [r/min]

Note

The above calculation formulae assume that the maximum motor toque is 150% of the rated torque.

A-10-2

Inverter Capacity Selection

Select an inverter that can be used with the motor you selected based on the result of motor capacity

selection.

Appendices

A-298

M1 Series EtherCAT Type User’s Manual (I670)

Loading...

Loading...