Be sure

to

wear

heavy gloves

10

avoid bums when

handling the heated

case cover.

Using a lorch

10

heal the cover

may

cause warpage.

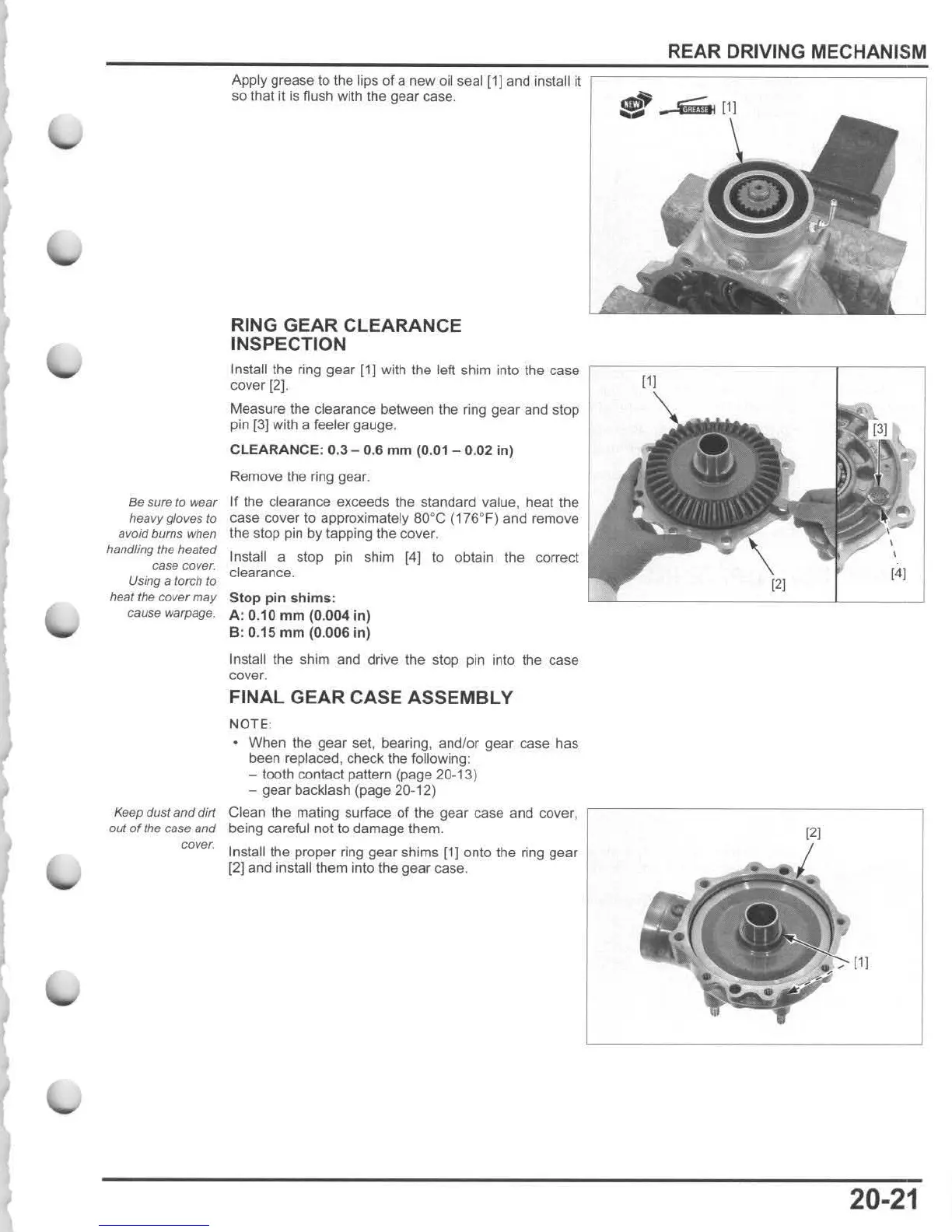

Apply grease to

the

lips

of

a new oil seal [1] and install it

so that it is flush wilh

Ihe gear case.

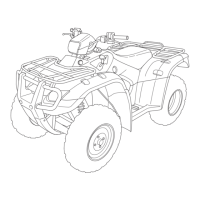

RING GEAR CLEARANCE

INSPECTION

Install the ring gear

[1)

with the left shim into the case

cover

[2].

Measure

the

clearance between the ring gear

and

stop

pin

[3]

with a feeler gauge.

CLEARANCE: 0.3 - 0.6

mm

(0,01 - 0 .02 in)

Remove the ring gear.

If Ihe clearance exceeds Ihe standard value. heat the

case cover to approximately

80°C (176°F) and remove

the stop

pin

by

tapping

the

cover.

Install a stop pin shim

[4]

to

obtain the correct

clearance.

Stop

pin

shims:

A: 0.10

mm

(0

.004 in)

B: 0.15

mm

(0

.006 in)

Inslall the shim and drive the stop pin inlo the case

cover.

FINAL GEAR CASE ASSEMBLY

NOT E:

When

the

gear sel, bearing, and/or gear case has

been replaced, check the

following:

- looth contact pattern (page 20-13)

- gear

backlash (page 20-12)

REAR DRIVING MECHANISM

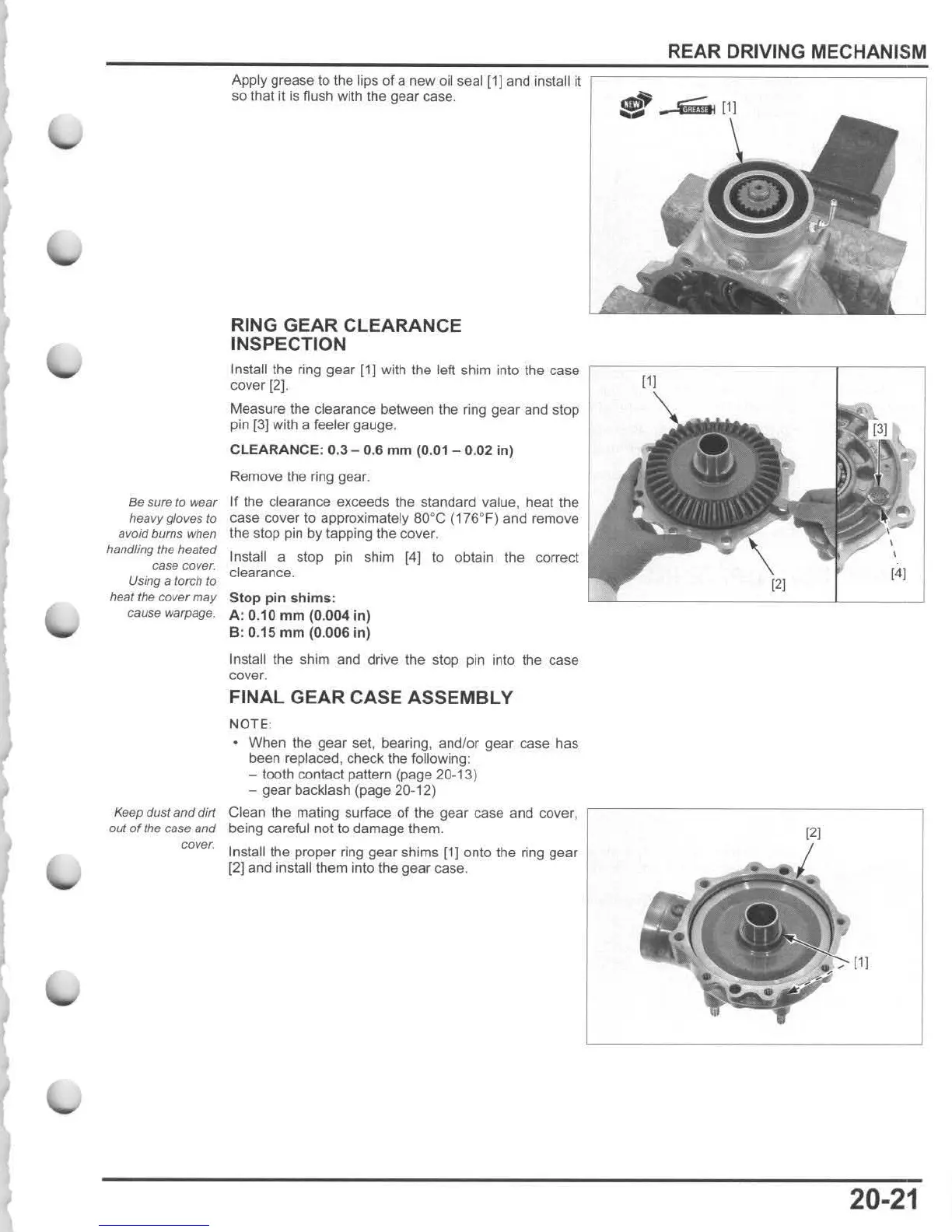

Keep

dusl

and

dirt Clean Ihe mating surface

of

the gear case and cover.

~-

----------------

~

out

of

the case

and

being careful nol

to

damage them.

cover.

Inslall the proper ring gear shims [1] onto Ihe ring gear

[2] and

install them into the gear case.

12J

I1J

20·21

Loading...

Loading...