Appendix-698 Cooperative operation function

7Appendix

(2) Adjustment 2: Setting of the common tool

Use the robot program BFRM.prg to set the common tool in robot No.1 and robot No.2. (Establish the tool

position at midpoint between the workpiece grasp positions for robot No.1 and robot No.2.)

■Outline of setting procedure

1) Teach the workpiece grasp positions for robot No.1 and robot No.2. (PPK1, PPK2)

(PPK1: Workpiece picking position of robot 1. PPK2: Workpiece picking position of robot 2.)

2) Set the tool coordinate of robot 1.

<Program>

PBT=(PPK1+PPK2)/2 ‘ Determine the midpoint by calculation between the work-

piece removing positions for robot No.1 and robot No.2.

PTL=Inv(PPK1)*PBT ‘ Determine the common tool by calculation in robot No.1 and

robot No.2.

Tool PTL

3) Set the tool coordinate of robot 2.

<Program>

PBT=(PPK1+PPK2)/2 ‘ Determine the midpoint by calculation between the work-

piece removing positions for robot No.1 and robot No.2.

PTL=Inv(PPK2)*PBT ‘ Determine the common tool by calculation in robot No.1 and

robot No.2.

Tool PTL

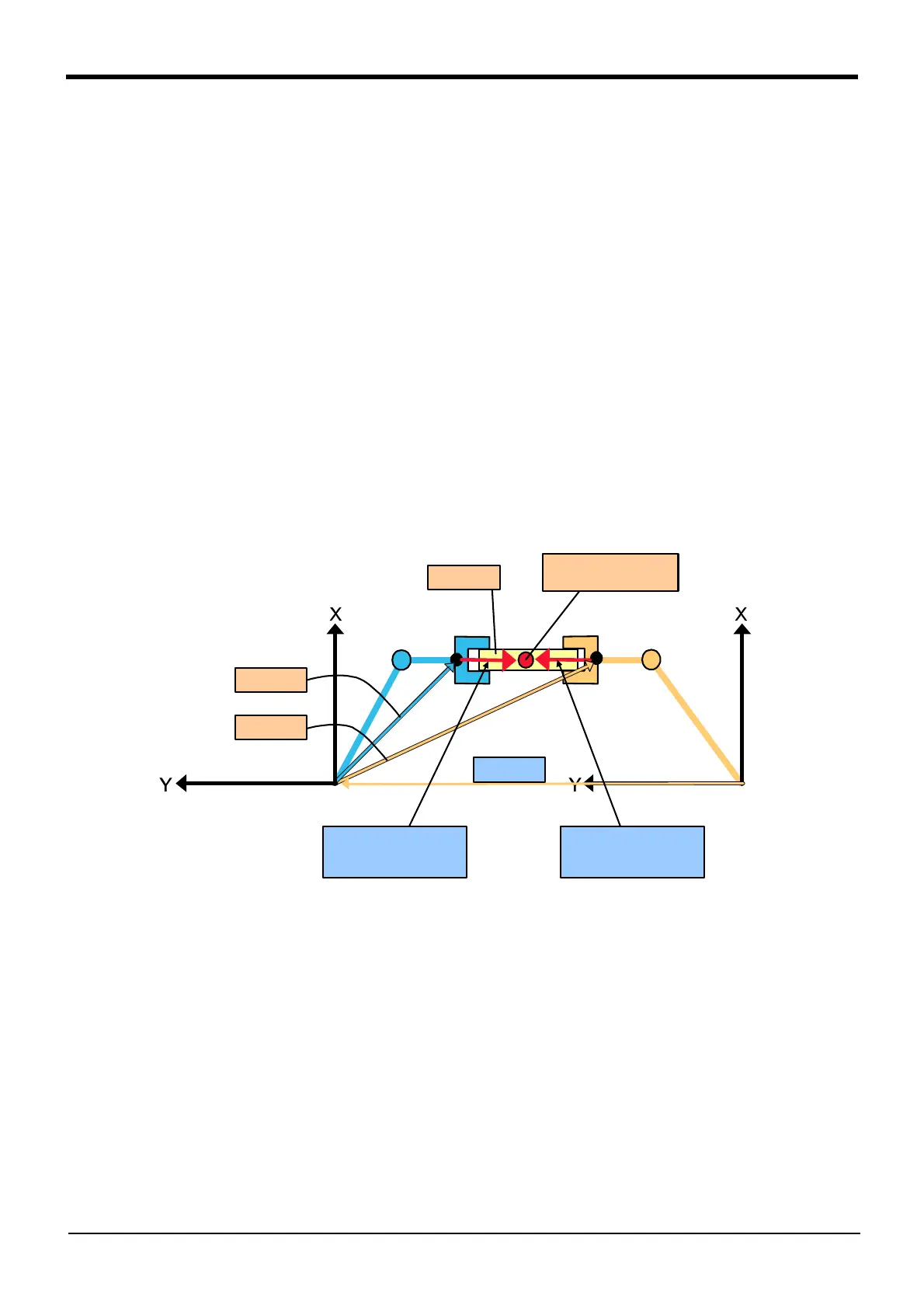

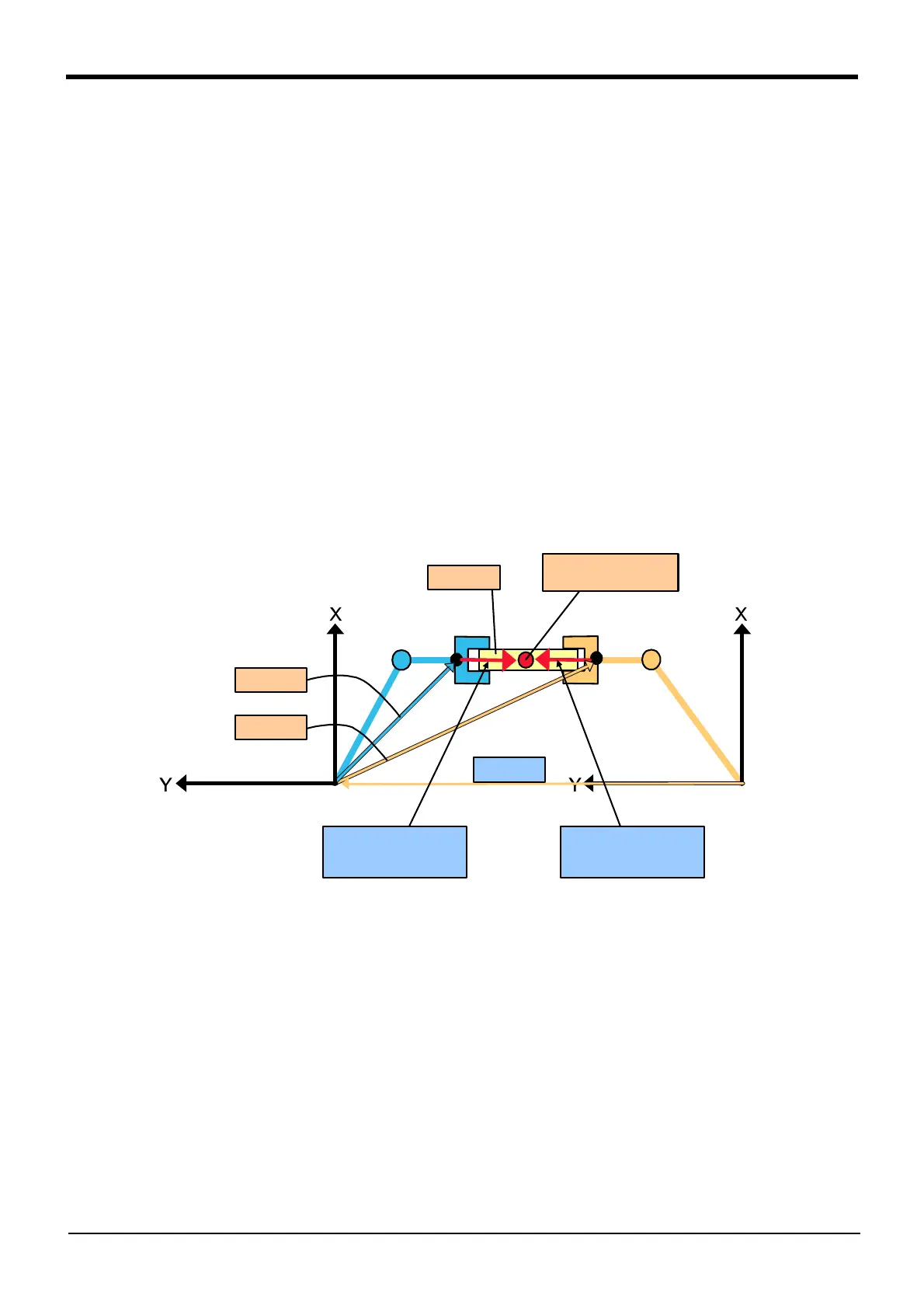

Fig.7-122:Setting of the common tool

Common tool

position

Wprkpiece

PPK1

PPK2

PBASE

Robot No.1 tool

(PLT1)

Robot No.2 tool

(PLT2)

Robot No.1

(Master)

Robot No.2

(Slave)

Loading...

Loading...