Rockwell Automation Publication 2198-UM001M-EN-P - November 2022 215

Appendix D Motor Control Feature Support

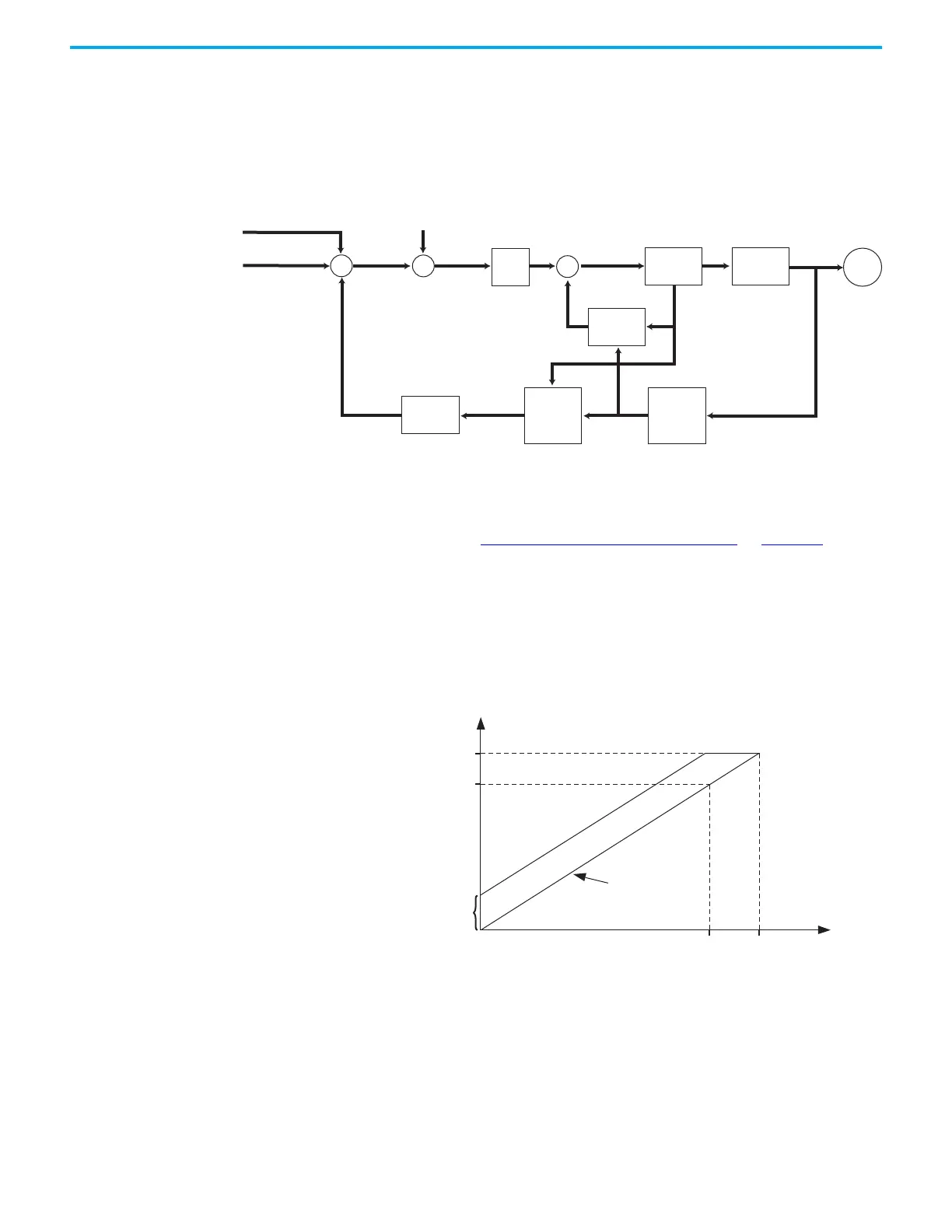

Sensorless Vector

The Sensorless Vector method uses a volts/hertz core that is enhanced by a

current resolver, slip estimator, and a voltage-boost compensator based on the

operating conditions of the motor.

Figure 117 - Sensorless Vector Method

The algorithms operate on the knowledge of the relationship between the rated

slip and torque of the motor. The drive uses applied voltages and measured

currents to estimate operating slip-frequency. You can enter values to identify

the motor resistance value or you can run a motor test to identify the motor

resistance value (see Motor Tests and Autotune Procedure

on page 228). Motor

nameplate data and test results are ways to accurately estimate the required

boost voltage.

The sensorless vector method offers better torque production and speed

regulation over a wider speed range than basic volts/hertz.

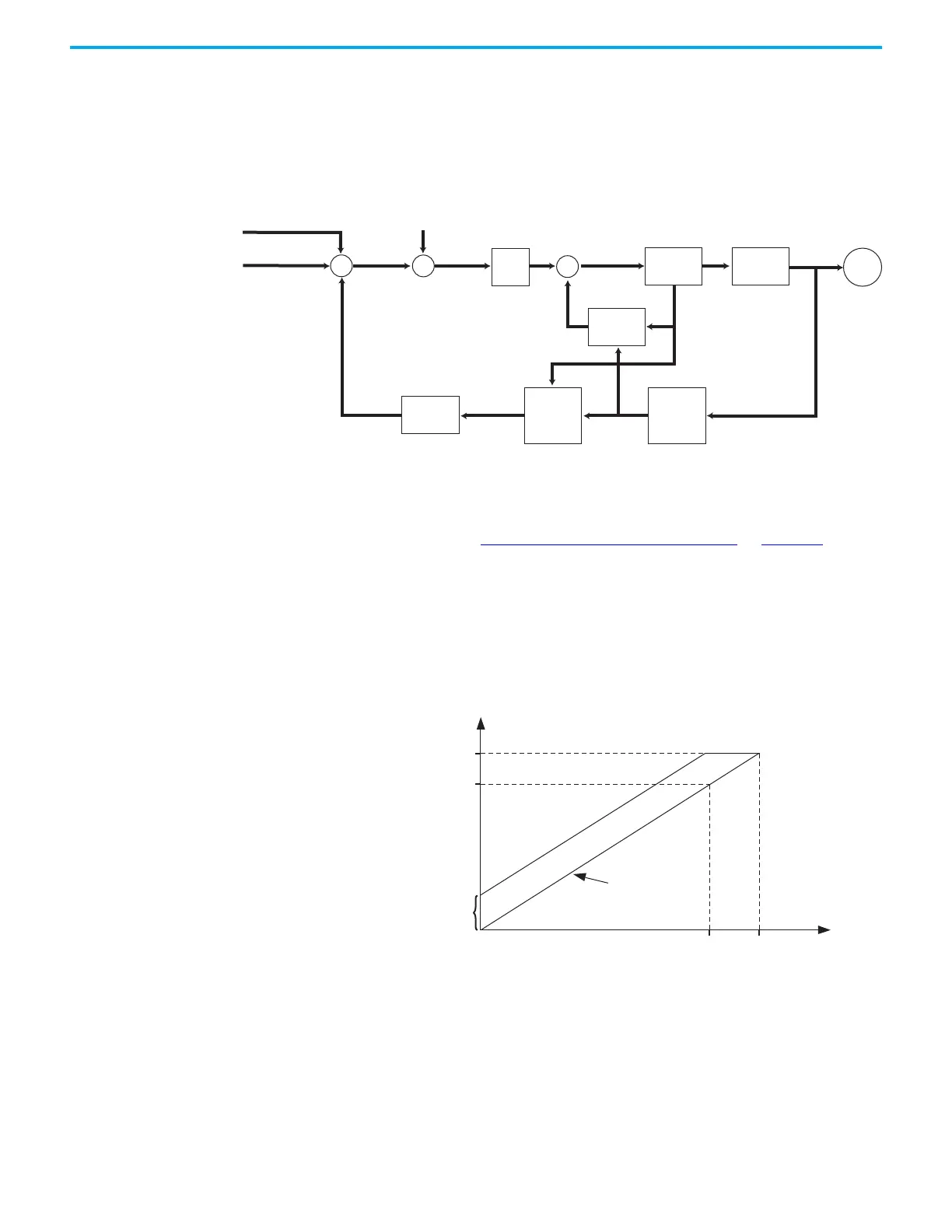

Dynamic boost is applied internally to compensate voltage drop and improve

starting torque.

Figure 118 - Approximate Load Curve

Velocity Trim

Velocity Command

Slip Speed

VHz

Motor Pole

Pairs

Vboost

Estimator

Voltage

Control

Current

Feedback

Current

Resolver

Torque

Estimate

Load

Torque

Estimator

Slip

Estimation

Inverter

Motor

Frequency,

max

Ideal, volts/hertz

Base Frequency

(nameplate)

Dynamic Boost Applied

Base Voltage

(nameplate)

Voltage, max

Loading...

Loading...