42 Rockwell Automation Publication 2198-UM001M-EN-P - November 2022

Chapter 2 Plan the Kinetix 5500 Drive System Installation

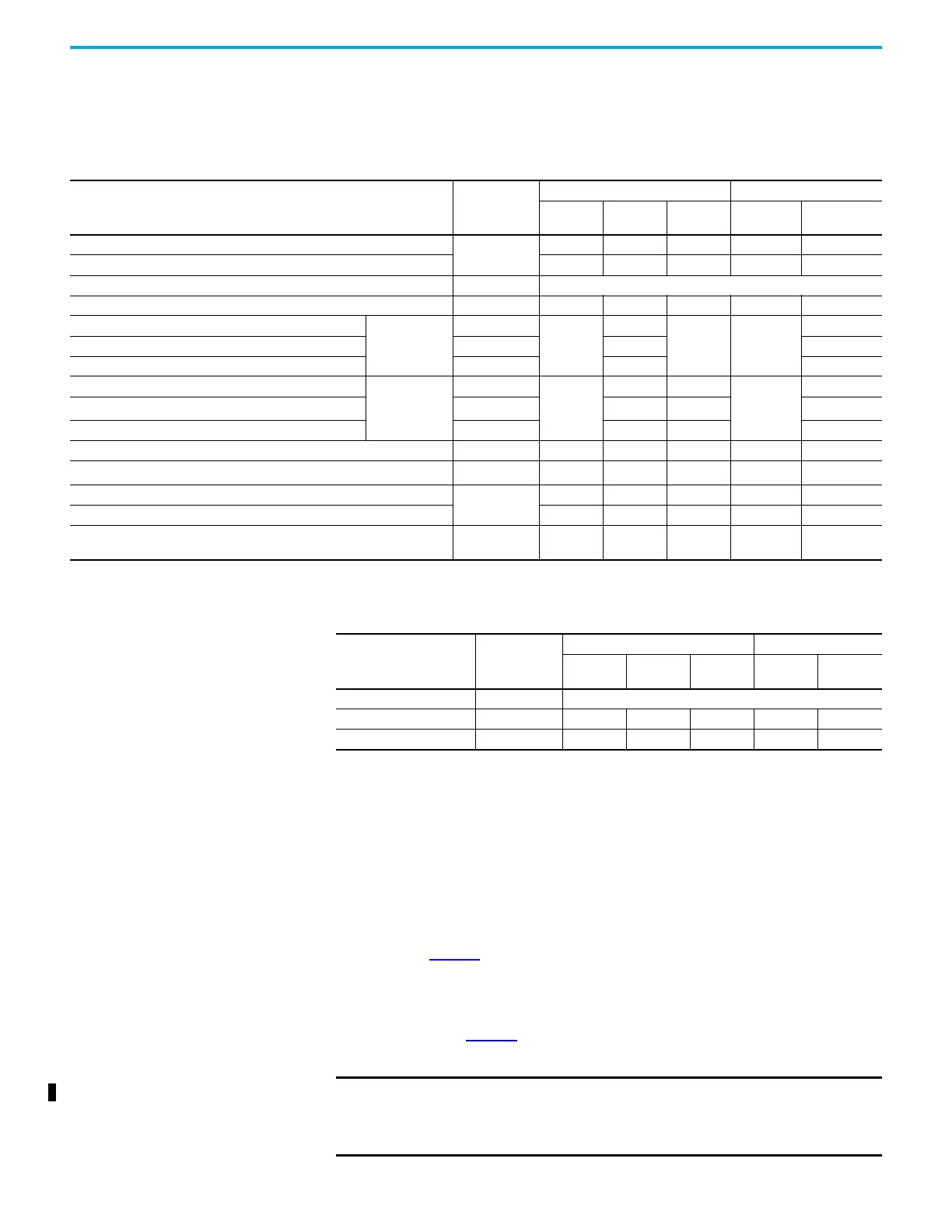

Cable Categories for Kinetix 5500 Systems

These tables indicate the zoning requirements of cables connecting to the

Kinetix 5500 drive components.

Noise Reduction Guidelines for Drive Accessories

See this section when mounting an AC (EMC) line filter or external

passive-shunt resistor for guidelines that are designed to reduce system

failures caused by excessive electrical noise.

AC Line Filters

Observe these guidelines when mounting your AC (EMC) line filter (refer to

the figure on page 41

for an example):

• Mount the AC line filter on the same panel as the Kinetix 5500 drive and

as close to the drive as possible.

• Good HF bonding to the panel is critical. For painted panels, refer to the

examples on page 39

.

• Separate input and output wiring as far as possible.

Table 18 - Kinetix 5500 Drive

Wire/Cable Connector

Zone Method

Very Dirty Dirty Clean

Ferrite

Sleeve

Shielded Cable

L1, L2, L3 (shielded cable)

IPD

—X —— X

L1, L2, L3 (unshielded cable) X — — — —

DC-/DC+ (DC bus) DC Busbar only, no wiring connector.

DC+/SH (shunt) RC — X — — —

U, V, W (motor power)

Kinetix VP

motors/

actuators

MP

—

X

——

X

Motor feedback MF X X

Motor brake BC X X

U, V, W (motor power)

Kinetix MP

motors/

actuators

MP

—

X—

—

X

Motor feedback

(1)

MF — X X

Motor brake BC X — X

24V DC CP — X — — —

Safety enable for Safe Torque Off (hardwired)

(2)

STO — X — — —

Registration input

IOD

——X — X

Dedicated digital inputs (other than registration inputs) — X — — —

Ethernet

PORT1

PORT2

——X — X

(1) When the 2198-H2DCK converter kit is used, the feedback cable routes in the clean wireway.

(2) STO connector applies to only 2198-Hxxx-ERS (hardwired) servo drives.

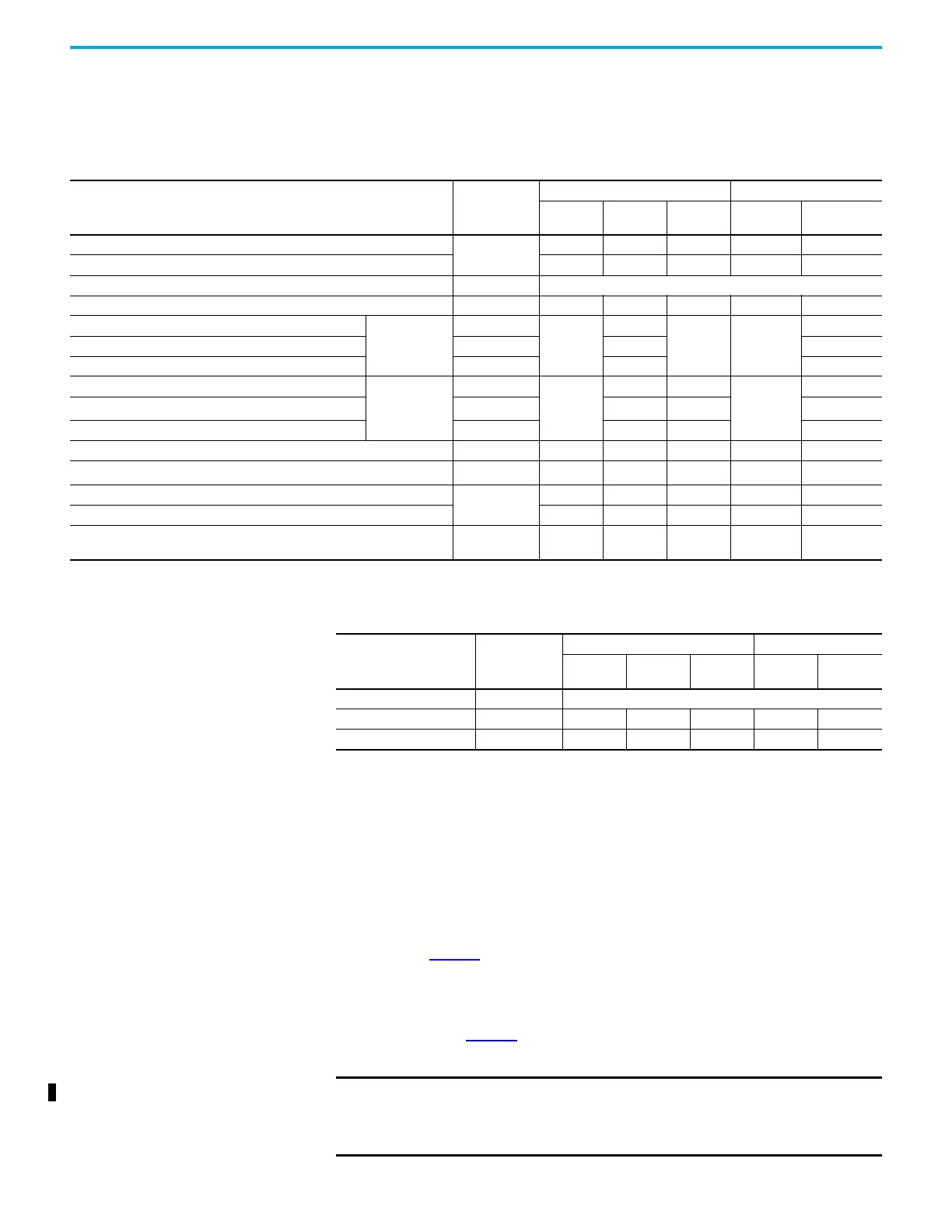

Table 19 - Capacitor Module

Wire/Cable Connector

Zone Method

Very Dirty Dirty Clean

Ferrite

Sleeve

Shielded

Cable

DC-/DC+ (DC bus) DC Busbar only, no wiring connector.

24V DC CP — X — — —

Module status MS — X — — —

IMPORTANT CE and UK test certification applies to only the AC line filter used with a

single drive or the line filter used in multi-axis drive configurations.

Sharing a line filter with more than one multi-axis drive configuration

can perform satisfactorily, but the customer takes legal responsibility.

Loading...

Loading...