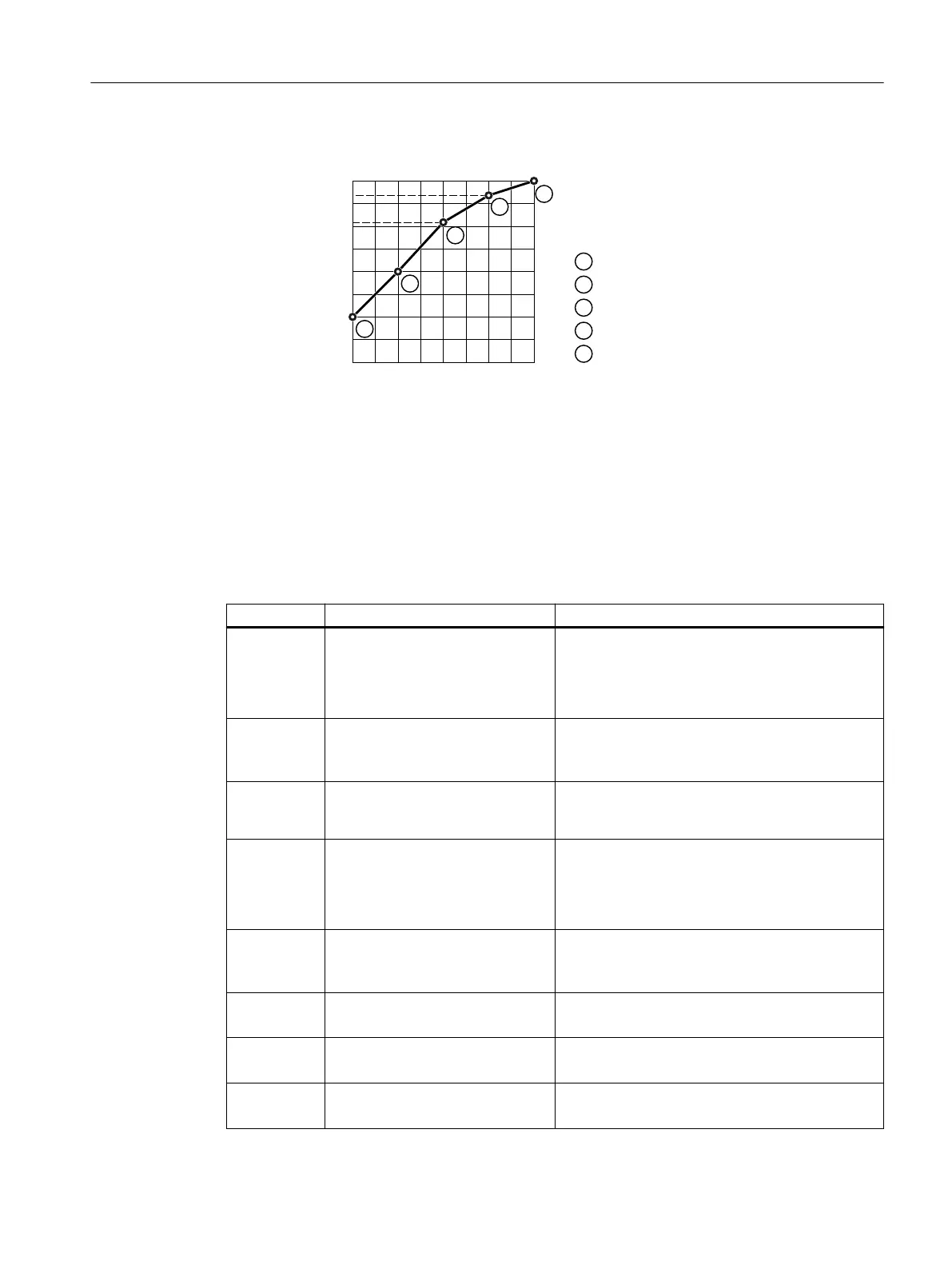

Flow characteristic

6SHHGLQ

3RZHULQ

6SHHGSRZHU

SS

SS

SS

SS

SS

To set the characteristic, you require the following data from the machine manufacturer for

each speed interpolation point:

• The ow rate of the uid-ow machine associated with the 5 selected converter speeds

• At constant speed, the power drawn which is associated with the 5 ow rates corresponds to

the line frequency and mechanical throttling of the ow rate.

Parameters

Parameter Description Setting

r0039[0...2] CO: Energy display [kWh] [0] Energy consumption since the last reset.

[1] Energy drawn since the last reset.

[2] Energy fed back since the last reset.

r0039 serves as reference signal of r0042.

p0040 Reset energy consumption display Setting p0040 = 1 to reset the display in r0039 and

r0041.

Factory setting: 0

r0041 Energy saved [kWh] Displays the saved energy referred to 100 operat‐

ing hours. For an operating time of below 100

hours, the display is interpolated up to 100 hours.

r0042[0...2] CO: Process energy display [Wh] [0] Energy consumption since the last reset.

[1] Energy drawn since the last reset.

[2] Energy fed back since the last reset.

For display as process variable. Enable with p0043.

p0043 BI: Energy consumption display en‐

abled

Sets the signal source (BI: p0043 = 1 signal) to en‐

able/reset the process energy display in r0042.

Factory setting: 0

p3320[0…n] Fluid ow machine power, point 1

[%]

Species the power (P) of point 1 as a [%].

Factory setting: 25

p3321[0…n] Fluid ow machine speed, point 1

[%]

Species the speed (n) of point 1 as a [%].

Factory setting: 0

p3322[0…n] Fluid ow machine power, point 2

[%]

Species the power (P) of point 2 as a [%].

Factory setting: 50

Advanced commissioning

7.29Calculating the energy saving for uid ow machines

SINAMICS G115D Wall Mounted distributed drive

Operating Instructions, 07/2023, FW V4.7 SP14, A5E52808211A AA 339

Loading...

Loading...