12.3.8 Gearbox with foot mounting

The foundation should be designed in such a way that no resonance vibrations are created and

no vibrations are transmitted from adjacent foundations.

The foundation structure on which the gearbox is to be mounted must be torsionally

rigid. It must be dimensioned according to the weight and torque, taking into account the

forces acting on the gearbox. If the substructure is too weak, it will cause radial or axial

displacement oset during operation that cannot be measured at a standstill.

If the gearbox is fastened to a concrete foundation, use foundation blocks for the appropriate

recesses.

Align and grout the slide rails into the foundation.

Align the gearbox carefully with the units on the input and output side. Take into account the

elastic deformation due to operating forces.

Prevent displacement from external forces due to lateral impacts.

Use stud bolts or headless screws of property class8.8 or higher for the mounting foot.

Observe the tightening torque.

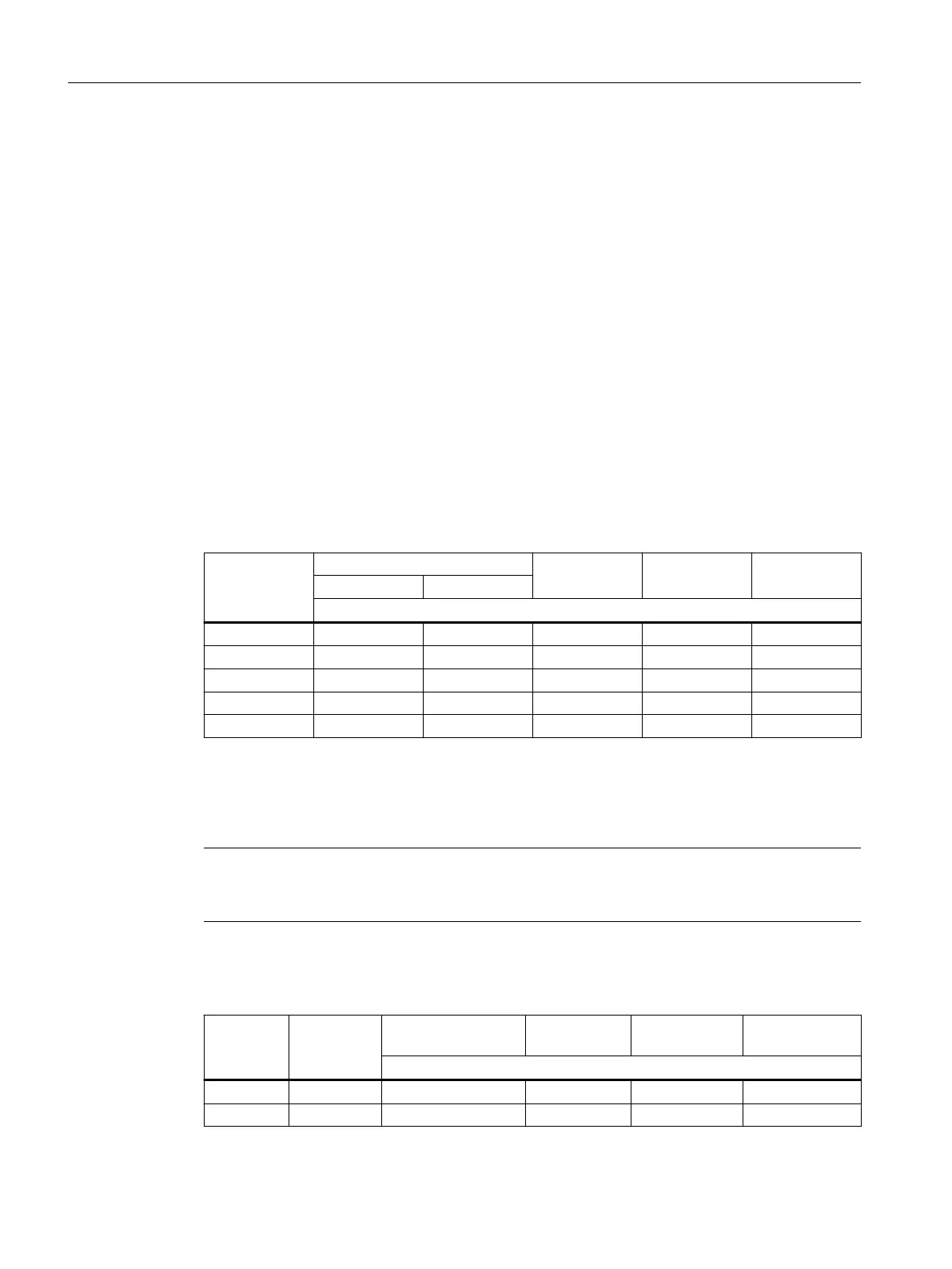

Table 12-30 Thread size of the xing screw

Thread size Helical gearbox Parallel shaft

gearbox F

Bevel gearbox

B,K

Helical worm

gearboxC

E D/Z

Size

M8 ‑ 19, 29, 39 29, 39 B19, B29, B39 29

M10 39 ‑ 49 B49, K39, K49 39, 49

M12 49 49, 59, 69 69, 79 K69, K79 69

M16 69, 89 79, 89 89 K89 89

M20 ‑ ‑ ‑ K109 ‑

12.3.9 Gearbox with ange mounting

Note

Siemens recommends an anaerobic adhesive to enhance the friction lock between ange and

mounting surface.

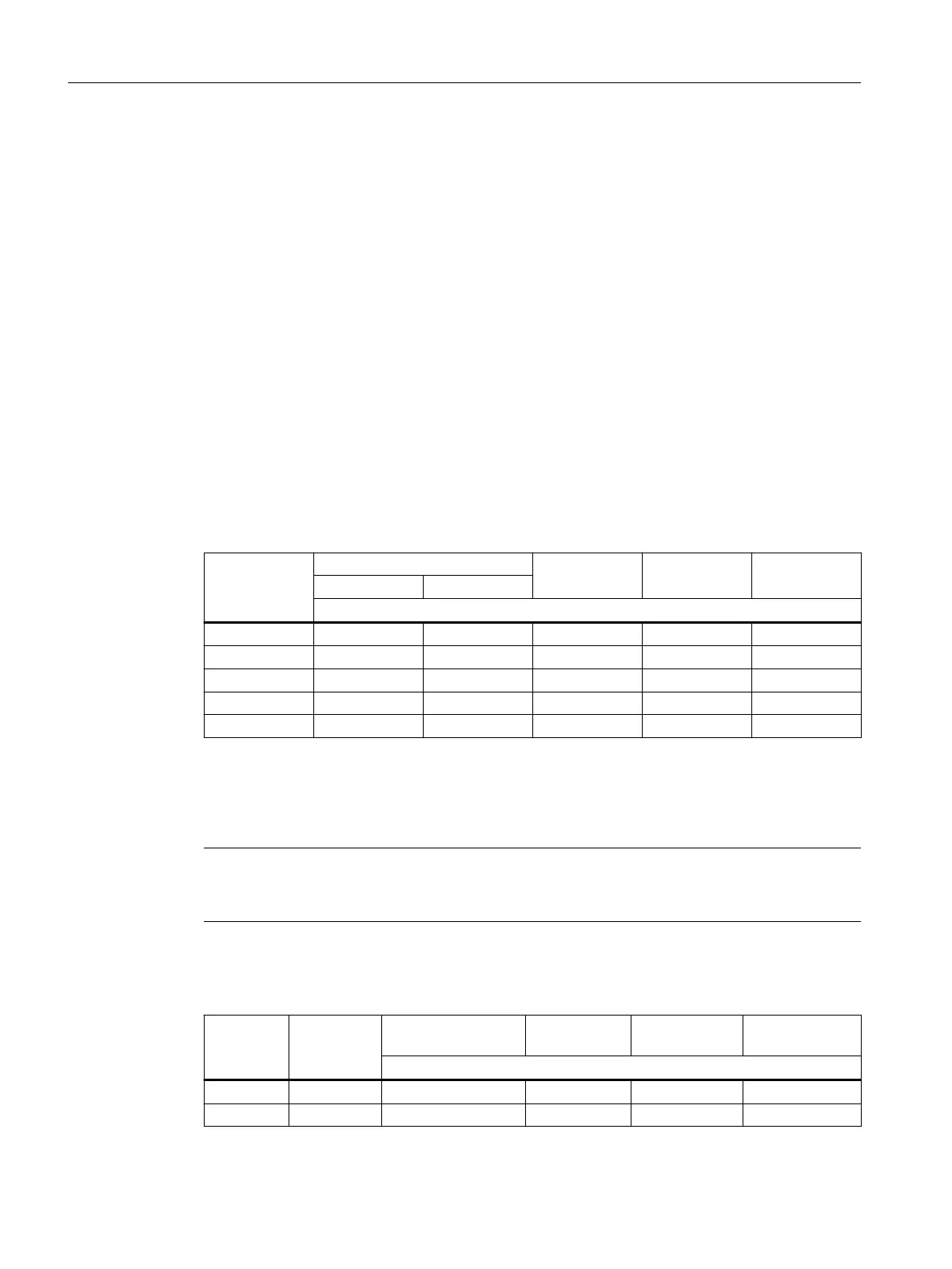

Table 12-31 Thread size of the xing screw

Thread

size

Flange Helical gearbox

E, D/Z

Parallel shaft

gearbox F

Bevel gearbox

B,K

Helical worm

gearboxC

Size

M6 A120 19,29,39 29 B19,B29 29

M8 A140,A160 19,29,39,49,59 29,39 B29,B39,K39 29,39

Additional information on the SIMOGEAR geared motor

12.3Specic data gearbox

SINAMICS G115D Wall Mounted distributed drive

486 Operating Instructions, 07/2023, FW V4.7 SP14, A5E52808211A AA

Loading...

Loading...