Note

Coat the contact surfaces with the mounting paste supplied with the product or any suitable

lubricant to prevent frictional corrosion.

Note

Observe the permissible concentricity tolerance of the cylindrical shaft extension of the

machine shaft to the housing axle according to DIN42955.

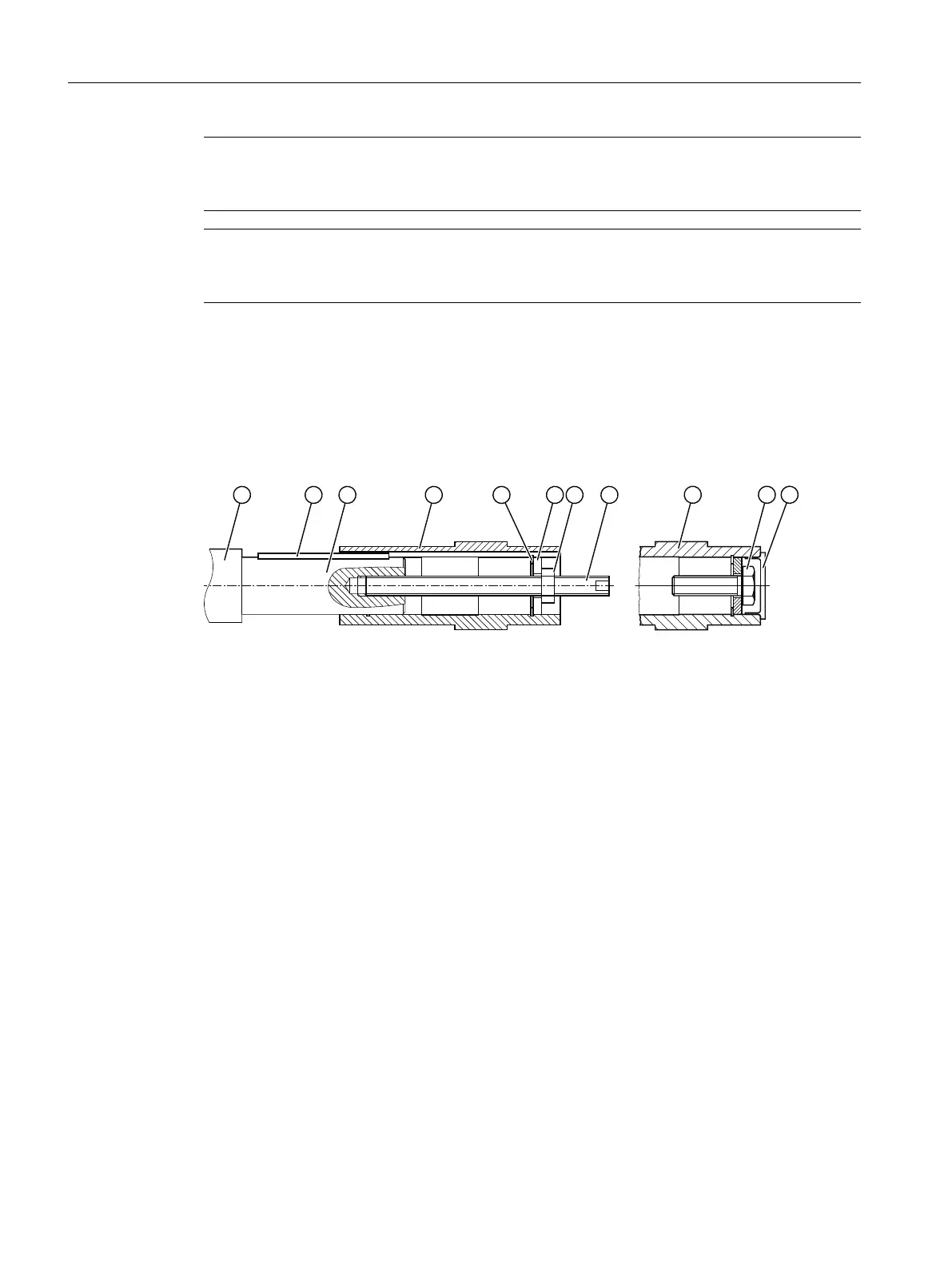

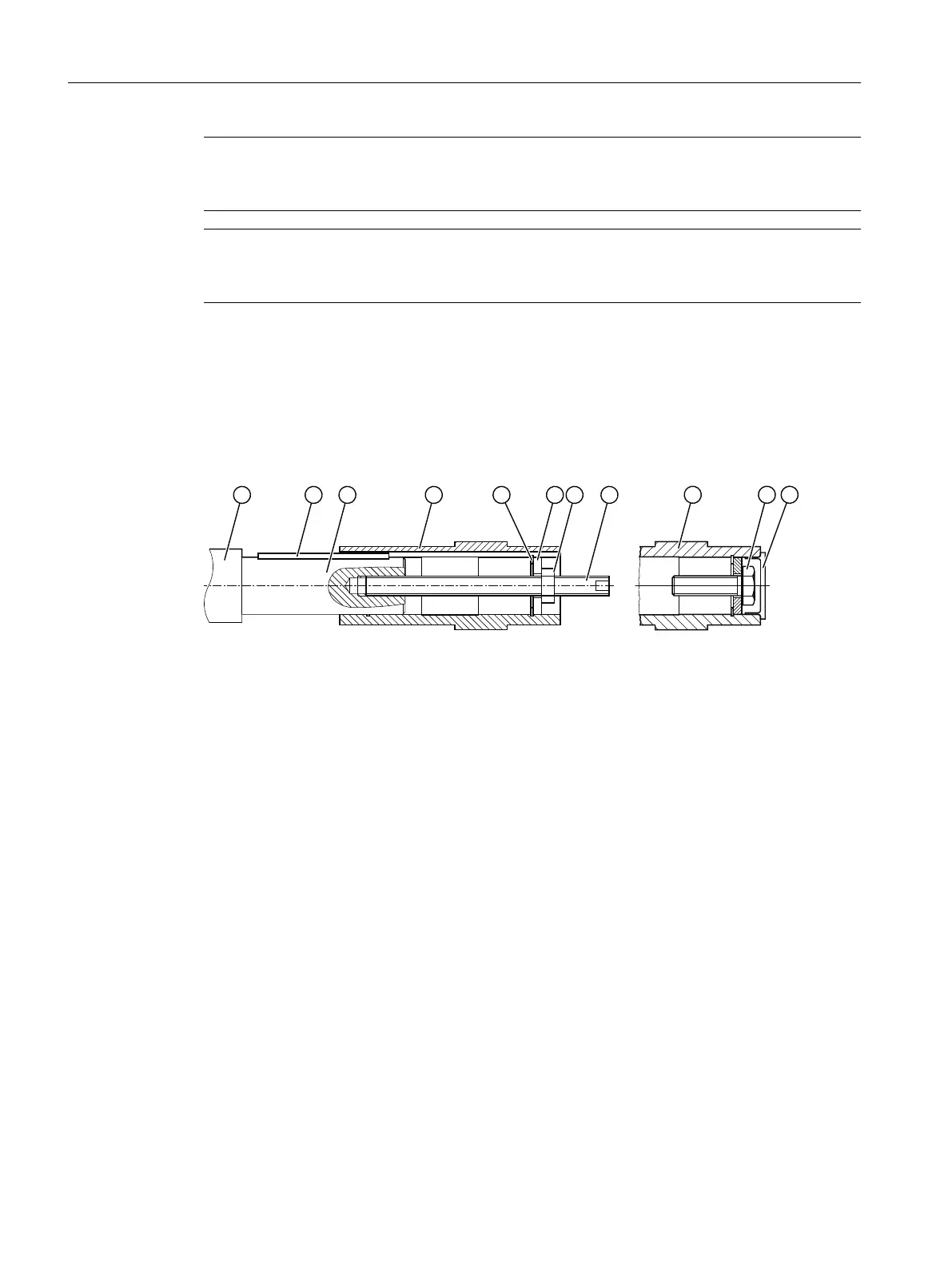

12.3.14 Hollow shaft with feather key

12.3.14.1 Mounting the hollow shaft with parallel key

* Not included in scope of supply

① Machine shaft ⑥ Locking ring

② Hollow shaft ⑦ Parallel key

③ Hexagon nut ⑧ Mounting paste

④ Threaded spindle ⑨ Screw

⑤ Disk ⑩ Sealing cap

Figure12-20 Mounting the hollow shaft with parallel key

Instead of the nut and threaded spindle shown in the diagram, other types of equipment

such as hydraulic lifting equipment may be used.

Procedure

1. Using benzine or a solvent, remove the anti-corrosion protection from the shaft ends and

anges.

2. Check the seats or edges of the hollow and machine shafts for any damage. Contact

Technical Support if you notice any damage.

3. Apply the mounting paste provided ① to the machine shaft ⑧. Apply the paste uniformly.

Carefully wipe away the rest at the shaft sealing ring of the gearbox.

4. Fit the gearbox using the disk ⑤, threaded spindle ④ and nut ③. Use the hollow shaft ②

for support.

Additional information on the SIMOGEAR geared motor

12.3Specic data gearbox

SINAMICS G115D Wall Mounted distributed drive

492 Operating Instructions, 07/2023, FW V4.7 SP14, A5E52808211A AA

Loading...

Loading...