Cable gland

NOTICE

Damage to the cable jacket

An excessively high tightening torque with a dierent cable jacket material will damage the

cable jacket.

When dierent cable jacket materials are used, apply a lower tightening torque.

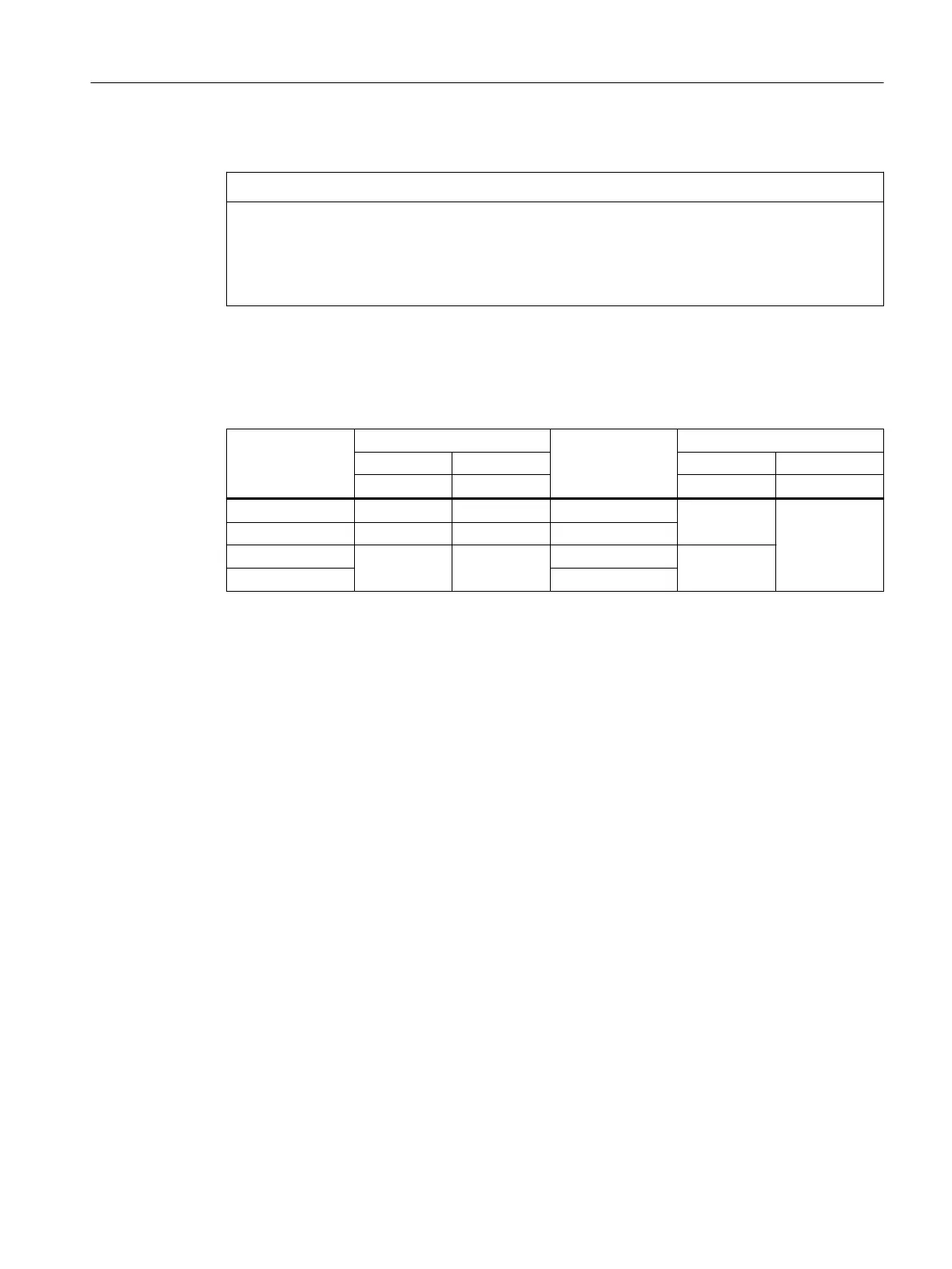

For metal or plastic cable glands, please use the following tightening torques for direct

mounting. The O-ring cross-section is 2mm.

Table 12-14 Tightening torque for cable glands and blanking plugs

Thread size Tightening torque ±10% Thread size Tightening torque ±10%

Metal Plastic Metal Plastic

Nm Nm Nm Nm

M12x1.5 8 1.5 M32x1.5 18 6

M16x1.5 10 2 M40x1.5

M20x1.5 12 4 M50x1.5 20

M25x1.5 M63x1.5

12.2.11 Converter operation

Suitably shielded cables and EMC cable glands must be used to connect the motors.

The maximum length of the motor cables is 15m (49ft), see section AUTOHOTSPOT.

Permissible voltage stress

For drives with G115D and EMC-adequate connection, the motor windings are designed to

be converter-suitable (against partial discharge).

Bearing currents

Additional bearing currents due to steep voltage edges when switching. Make sure the drive

system is installed in accordance with EMC requirements.

Mechanical stress and grease lifetime

High speeds that exceed the rated speed and the resulting increased vibrations alter the

mechanical running smoothness and the bearings are subjected to increased stress. This

reduces the service life of the grease and bearings.

Additional information on the SIMOGEAR geared motor

12.2Specic data motor

SINAMICS G115D Wall Mounted distributed drive

Operating Instructions, 07/2023, FW V4.7 SP14, A5E52808211A AA 459

Loading...

Loading...