NOTICE

Improper maintenance

Only authorized qualied personnel may perform the maintenance and servicing. Only original

parts supplied by Siemens may be installed.

Only qualied personnel may perform the inspection, maintenance and service work.

Carefully follow the General information gearbox (Page479).

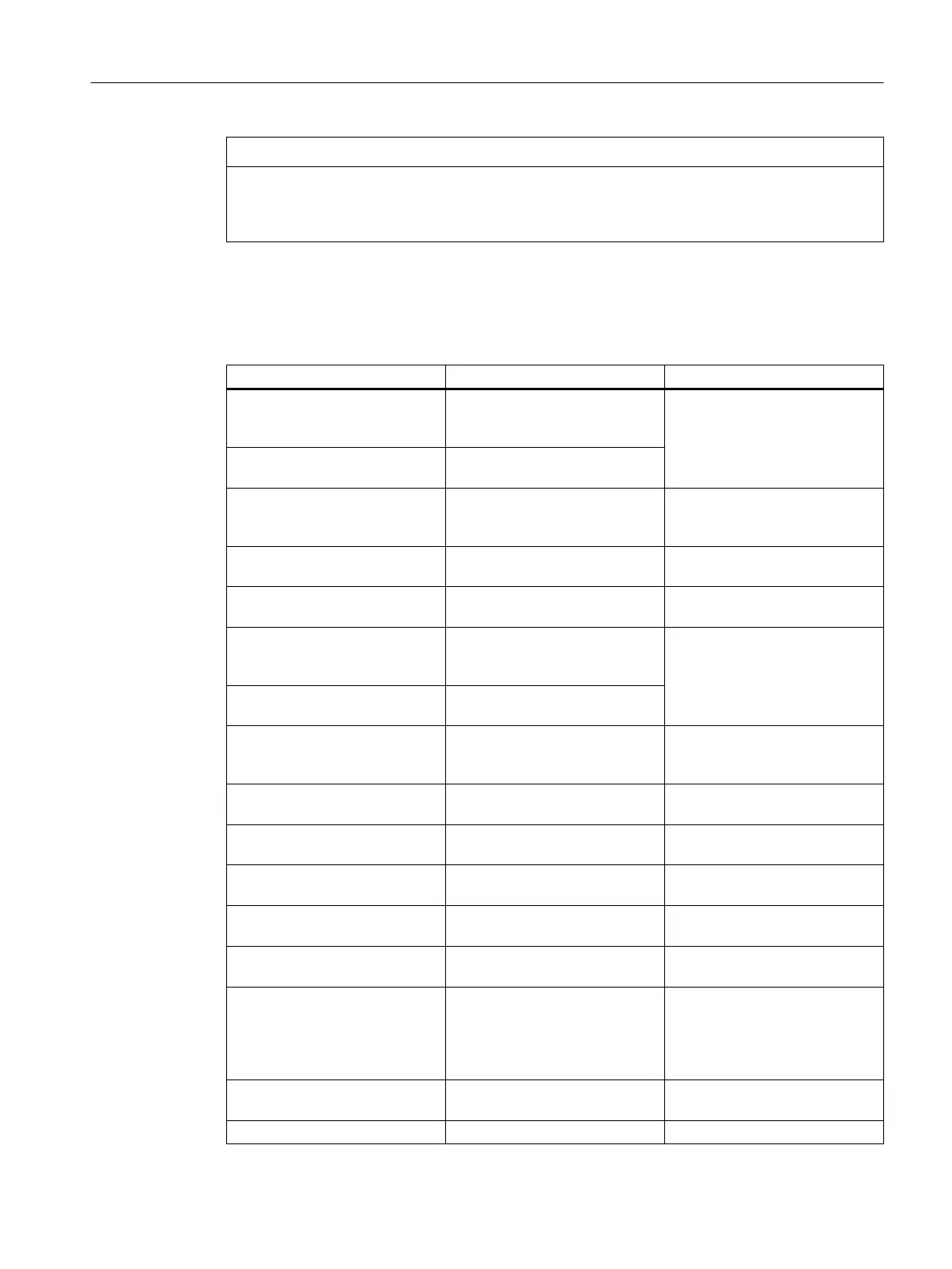

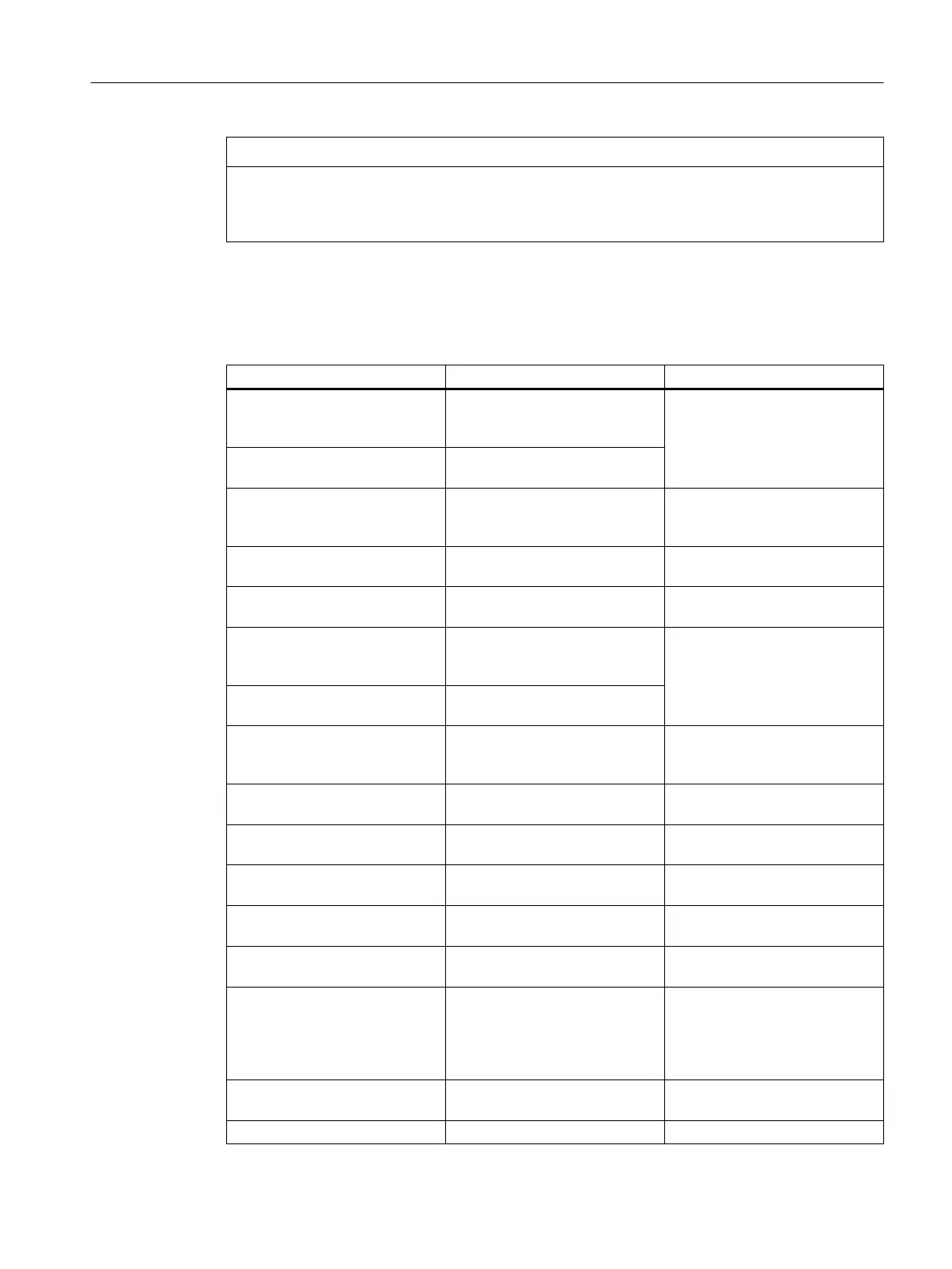

Table 12-42 Maintenance measures

Remedy Interval Description of work

Monitor andcheck the geared

motor for unusual noise, vibra‐

tions, and changes.

Daily; if possible, more frequent‐

ly during operation.

Operation (Page437)

Check the housing temperature. After 3hours, on the rst day,

thereafter monthly.

Check the oil level. After the rst day, and then every

3000 operating hours, or at the

latest after 6months.

Checking and changing lubri‐

cants (Page514)

Check the oil level sensor Regularly and after oil changes. Checking the oil level sensor (op‐

tional) (Page525)

Check the oil quality. Every 6months. Checking the oil quality

(Page517)

First oil change after commission‐

ing.

After approximately 10000oper‐

ating hours or at the latest after

2years.

Checking and changing lubri‐

cants (Page514)

Subsequent oil changes. Every 2 years or 10000 operating

hours

1)

.

Visual inspection of the gear‐

boxandshaft sealing ring for

leaks.

After the rst day, thereafter

monthly.

Checking the gearbox for leaks

(Page525)

When required, replace the

breather valve.

Once a year. Replacing the vent valve

(Page525)

Clean the gearbox. Depending on degree of soiling,

at least every 6months.

Cleaning the geared motor

(Page437)

Carry out a complete inspection

of the geared motor.

Every 12months. Inspecting the geared motor

(Page438)

Check the friction clutch and ad‐

just if necessary.

After 500 hours, thereafter once

a year and after every blockage.

Follow the BA 2039 Operating In‐

structions.

Check the coupling. For the rst time after 3months. Follow the separate operating in‐

structions.

Check that fastening bolts on

gearboxes and add-on elements

are securely tightened. Check

that covers and plugs are secure‐

ly fastened.

After 3hours, and then every 2

years.

Checking the tightness of fasten‐

ing bolts (Page526)

Change the roller bearing grease. When the oil is changed. Change the roller bearing grease

(Page521)

Replace the bearing. - Replace bearings (Page524)

Additional information on the SIMOGEAR geared motor

12.3Specic data gearbox

SINAMICS G115D Wall Mounted distributed drive

Operating Instructions, 07/2023, FW V4.7 SP14, A5E52808211A AA 513

Loading...

Loading...